About Selecting a Mixer

More

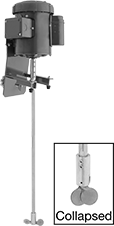

Electric Mixers for Tanks

Attach these mixers to your tank wall. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing. Motor is totally enclosed fan cooled (TEFC) for use in environments with splashing water and dust.

Mixers with two propellers are used for thorough mixing in tanks that are deeper than they are wide and for faster mixing than mixers with one propeller.

Mixers with high-flow propellers have specialized propellers for 40% greater flow than standard propellers.

Mixers for thin liquids are for liquids with a viscosity similar to water and light oils. Also known as direct-drive mixers, they operate at high speeds for rapid tank turnover.

Mixers for thick liquids are for liquids with a viscosity similar to honey and molasses. Also known as gear-drive mixers, they turn propellers at low speeds.

Propellers | Shaft | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Features | Each | |

120/240V AC Single Phase—Wire Leads | ||||||||||||||

For Thin Liquids | ||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 4.4/2.2 | 60 | 51" | 48 | 3" | High-Flow Propeller | 00000000 | 000000000 |

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 4.4/2.2 | 60 | 63" | 49 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 32" | 5/8" | 6/3 | 60 | 45 1/2" | 53 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 6/3 | 60 | 61 1/2" | 54 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 5/8" | 6/3 | 60 | 73 1/2" | 59 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/2 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 7.4/3.7 | 60 | 61 1/2" | 61 | 3" | __ | 00000000 | 00000000 |

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 3/4" | 8.4/4.2 | 60 | 73 1/2" | 68 | 3" | __ | 00000000 | 00000000 |

| 3/4 | 1,725 | 2 | 4" | 316 Stainless Steel | 48" | 3/4" | 10.8/5.4 | 60 | 70 1/4" | 66 | 4" | __ | 0000000 | 00000000 |

For Thick Liquids | ||||||||||||||

| 1/4 | 350 | 1 | 7 5/8" | 316 Stainless Steel | 36" | 3/4" | 4.4/2.2 | 60 | 53 5/8" | 59 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/4 | 350 | 1 | 10" | 316 Stainless Steel | 48" | 3/4" | 4.4/2.2 | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 350 | 1 | 6" | 316 Stainless Steel | 32" | 3/4" | 6.6/3.3 | 60 | 49 5/8" | 52 | 4" | __ | 0000000 | 00000000 |

| 1/3 | 350 | 1 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 6/3 | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 350 | 2 | 7 5/8" | 316 Stainless Steel | 36" | 3/4" | 6/3 | 60 | 53 5/8" | 60 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 350 | 2 | 10" | 316 Stainless Steel | 60" | 3/4" | 6/3 | 60 | 77 5/8" | 67 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/2 | 350 | 2 | 10" | 316 Stainless Steel | 48" | 3/4" | 8/4 | 60 | 66 1/2" | 62 | 4" | __ | 0000000 | 00000000 |

| 3/4 | 350 | 2 | 11" | 316 Stainless Steel | 60" | 3/4" | 10.8/5.4 | 60 | 78 3/4" | 71 | 4" | __ | 0000000 | 00000000 |

240/460V AC Three Phase—Wire Leads | ||||||||||||||

For Thin Liquids | ||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 1.3/0.7 | 60 | 51" | 48 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 3/1.5 | 60 | 61 1/2" | 72 | 3" | __ | 00000000 | 00000000 |

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.8/1.9 | 60 | 81 3/4" | 76 | 4" | __ | 0000000 | 00000000 |

For Thick Liquids | ||||||||||||||

| 1/3 | 350 | 1 | 6" | 316 Stainless Steel | 32" | 3/4" | 1.6/0.8 | 60 | 49 3/8" | 61 | 4" | __ | 0000000 | 00000000 |

| 1/3 | 350 | 1 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 1.6/0.8 | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1/3 | 350 | 2 | 10" | 316 Stainless Steel | 60" | 3/4" | 1.6/0.8 | 60 | 77 5/8" | 67 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 3/4 | 350 | 2 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 3/1.5 | 60 | 65 5/8" | 66 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 3/4 | 350 | 2 | 11 13/16" | 316 Stainless Steel | 60" | 3/4" | 3/1.5 | 60 | 77 5/8" | 68 | 3" | High-Flow Propeller | 00000000 | 00000000 |

| 1 1/2 | 350 | 2 | 13" | 316 Stainless Steel | 60" | 1" | 5/2.5 | 60 | 78 3/4" | 79 | 4" | __ | 0000000 | 00000000 |

Hazardous Location Electric Mixers for Tanks

Motor is UL listed for use in environments with flammable gases and combustible dust. Attach these mixers to your tank wall. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Mixer for thin liquids is for liquids with a viscosity similar to water and light oils. Also known as a direct-drive mixer, it operates at high speeds for rapid tank turnover.

Mixers for thick liquids are for liquids with a viscosity similar to honey and molasses. Also known as gear-drive mixers, they turn propellers at low speeds.

Propellers | Shaft | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Environmental Rating | Each | |

120/240V AC Single Phase—Wire Leads | ||||||||||||||

For Thick Liquids | ||||||||||||||

| 3/4 | 350 | 2 | 11" | 316 Stainless Steel | 60" | 3/4" | 11/5.5 | 60 | 81 1/2" | 84 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 000000000 |

240/460V AC Three Phase—Wire Leads | ||||||||||||||

For Thin Liquids | ||||||||||||||

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.6/1.8 | 60 | 84" | 78 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 00000000 |

For Thick Liquids | ||||||||||||||

| 1 1/2 | 350 | 2 | 13" | 316 Stainless Steel | 60" | 1" | 4.4/2.2 | 60 | 80 1/2" | 70 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 00000000 |

Food and Beverage Electric Mixers for Tanks

These mixers are CE marked, CSA certified, and CSA-US certified for use with food and beverages. Attach to your tank wall. The propeller is left hand and moves clockwise when viewed from above to direct flow downward for efficient mixing. It rotates propellers at a fixed speed. Motor is totally enclosed fan cooled (TEFC) for use in environments with splashing water and dust. All meet IP56 for resistance to dust and washdowns.

Mixer for thin liquids is for liquids with a viscosity similar to water and light oils. Also known as a direct-drive mixer, it operates at high speeds for rapid tank turnover.

Mixer for thick liquids is for liquids with a viscosity similar to honey and molasses. Also known as a gear-drive mixer, it turns the propeller at low speeds.

For technical drawings and 3-D models, click on a part number.

Propellers | Shaft | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Features | Environmental Rating | Each | |

240/460V AC Three Phase—Wire Leads | |||||||||||||||

For Thin Liquids | |||||||||||||||

| 1/2 | 1,750 | 1 | 3 5/8" | 316 Stainless Steel | 48" | 13/16" | 1.5/0.8 | 60 | 60 1/16" | 61 | 3" | __ | IP56 | 0000000 | 000000000 |

For Thick Liquids | |||||||||||||||

| 1/2 | 350 | 1 | 10" | 316 Stainless Steel | 48" | 13/16" | 1.5/0.8 | 60 | 60 1/16" | 64 | 3" | High-Flow Propeller | IP56 | 0000000 | 00000000 |

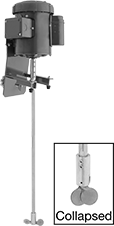

Variable-Speed Electric Mixers for Tanks

Turn the dial to adjust the speed of the propellers. These mixers attach to your tank wall. All have high-flow propellers that generate 40% greater flow than conventional propellers. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Use a mixer with two propellers for thorough mixing in tanks that are deeper than they are wide and for faster mixing than mixers with one propeller.

Mixers for thin liquids are for liquids with a viscosity similar to water and light oils. Also known as direct-drive mixers, they operate at high speeds for rapid tank turnover.

Mixers for thick liquids are for liquids with a viscosity similar to honey and molasses. Also known as gear-drive mixers, they turn propellers at low speeds.

Propellers | Shaft | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Cord Lg., ft. | Motor Enclosure Type | Each | |

120V AC Single Phase—Three-Prong Plug | |||||||||||||||

For Thin Liquids | |||||||||||||||

| 1/4 | 90-1,750 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 3.5 | 60 | 51" | 50 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 000000000 |

| 1/4 | 90-1,750 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 3.5 | 60 | 63" | 51 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

| 1/3 | 90-1,750 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 4.5 | 60 | 63" | 45 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

| 1/2 | 90-1,750 | 1 | 5 3/16" | 316 Stainless Steel | 48" | 3/4" | 6 | 60 | 63" | 55 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

For Thick Liquids | |||||||||||||||

| 1/4 | 20-350 | 1 | 10" | 316 Stainless Steel | 36" | 3/4" | 3.5 | 60 | 53 5/8" | 63 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

| 1/4 | 20-350 | 1 | 10" | 316 Stainless Steel | 48" | 3/4" | 3.5 | 60 | 65 5/8" | 65 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

| 1/2 | 20-350 | 1 | 11 13/16" | 316 Stainless Steel | 60" | 3/4" | 6 | 60 | 77 5/8" | 64 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

| 1/2 | 20-350 | 2 | 8 13/16" | 316 Stainless Steel | 48" | 3/4" | 6 | 60 | 65 5/8" | 61 | 3" | 7 1/2 | Totally Enclosed Nonventilated | 0000000 | 00000000 |

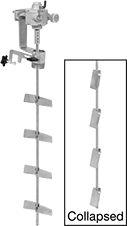

Clamp-Mount Air-Powered Mixers for Tanks

Attach these mixers to a tank wall. A needle valve allows you to adjust mixing speed. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Mixers with two propellers are used for thorough mixing in tanks that are deeper than they are wide and for faster mixing than mixers with one propeller.

Mixers with 2 horsepower motors can be set to move counterclockwise for aeration.

Mixers for thin liquids are for liquids with a viscosity similar to water and light oils. Also known as direct-drive mixers, they operate at high speeds for rapid tank turnover.

Mixers for thick liquids are for liquids with a viscosity similar to honey and molasses. Also known as gear-drive mixers, they turn propellers at low speeds.

Propellers | Shaft | Air Connection | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Includes | Each | |

For Thin Liquids | ||||||||||||||||

| 1 | 300-1,750 | 1 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 33" | 28 | 1 7/8" | Needle Valve | 00000000 | 000000000 |

| 1 | 300-1,750 | 1 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 42" | 28 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 1 | 300-1,750 | 1 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 54" | 37 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 1 | 300-1,750 | 2 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 33" | 30 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 1 | 300-1,750 | 2 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 42" | 30 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 1 | 300-1,750 | 2 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 cfm @ 80 psi | 54" | 39 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 1 | 8" | 316 Stainless Steel | 27" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 34 5/16" | 35 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 1 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 43 5/16" | 39 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 1 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 55 5/16" | 40 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 1 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 67 5/16" | 52 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 2 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 43 5/16" | 41 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 2 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 55 5/16" | 42 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

| 2 | 300-1,750 | 2 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 cfm @ 80 psi | 67 5/16" | 55 | 1 7/8" | Needle Valve | 00000000 | 00000000 |

For Thick Liquids | ||||||||||||||||

| 1/2 | 0-400 | 2 | 9" | 316 Stainless Steel | 30" | 3/4" | 1/4 | NPT | Female | 13 cfm @ 80 psi | 44" | 40 | 2 1/4" | Needle Valve | 0000000 | 00000000 |

| 1 | 0-400 | 2 | 11" | 316 Stainless Steel | 40" | 3/4" | 1/4 | NPT | Female | 25 cfm @ 80 psi | 55" | 52 | 2 1/4" | Needle Valve | 0000000 | 00000000 |

| 3 | 0-400 | 2 | 13" | 316 Stainless Steel | 48" | 1" | 1/2 | NPT | Female | 89 cfm @ 80 psi | 69" | 101 | 3 1/2" | Needle Valve | 0000000 | 00000000 |

| Includes | Each | |

| Body Gasket, Dead End Bearing, Drive End Bearing, Gasket End Cap, Push Pin, Shaft Seal, Vane, Vane Spring | 0000000 | 0000000 |

| For No. of Propellers | For Shaft Dia. | Lg. | Includes | Each | |

Air Motor | |||||

|---|---|---|---|---|---|

| 1, 2 | 5/8" | __ | __ | 000000000 | 0000000 |

| 1, 2 | 3/4" | __ | __ | 000000000 | 00000000 |

Exhaust Muffler | |||||

| 1, 2 | 5/8", 3/4" | __ | __ | 000000000 | 00000 |

Mixer Clamp Assembly | |||||

| 1, 2 | 5/8", 3/4" | __ | __ | 000000000 | 000000 |

Propeller | |||||

| 1, 2 | 5/8" | __ | __ | 000000000 | 000000 |

| 1, 2 | 3/4" | __ | __ | 000000000 | 000000 |

Shaft | |||||

| 1, 2 | 5/8" | 27" | __ | 000000000 | 000000 |

| 1, 2 | 5/8" | 36" | __ | 000000000 | 000000 |

| 1, 2 | 5/8" | 48" | __ | 000000000 | 000000 |

| 1 | 3/4" | 27" | __ | 000000000 | 000000 |

| 1, 2 | 3/4" | 36" | __ | 000000000 | 000000 |

| 1, 2 | 3/4" | 48" | __ | 000000000 | 000000 |

| 1, 2 | 3/4" | 60" | __ | 000000000 | 000000 |

Shaft Coupling | |||||

| 1, 2 | 5/8" | __ | Set Screws | 000000000 | 000000 |

| 1, 2 | 3/4" | __ | Set Screws | 000000000 | 000000 |

Clamp-Mount Electric Mixers for Small Batches

Attach to the rim of a batch can or small container. Also known as direct-drive mixers, these operate at high speeds for rapid turnover. Use them to mix liquids with a viscosity similar to water and light oils. Motor is totally enclosed fan cooled (TEFC) for use in environments with splashing water and dust. Propeller is left hand and moves clockwise when viewed from above to direct flow downward for efficient mixing.

Propellers | Shaft | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Cord Lg., ft. | Each | |

120V AC Single Phase—Three-Prong Plug | |||||||||||||||

For Thin Liquids | |||||||||||||||

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 12" | 5/16" | 50 | 1.6 | 60 | 18 7/16" | 10 | 2" | 6 | 0000000 | 0000000 |

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 18" | 5/16" | 50 | 1.6 | 60 | 24 7/16" | 11 | 2" | 6 | 0000000 | 000000 |

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 24" | 5/16" | 50 | 1.6 | 60 | 30 7/16" | 11 | 2" | 6 | 0000000 | 000000 |

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 30" | 5/16" | 50 | 1.6 | 60 | 36 7/16" | 11 | 2" | 6 | 0000000 | 000000 |

120/240V AC Single Phase—Wire Leads | |||||||||||||||

For Thin Liquids | |||||||||||||||

| 1/2 | 1,425 | 1 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 8.2/4.1 | 50 | 43 3/16" | 47 | 2" | __ | 0000000 | 00000000 |

| 1/2 | 1,725 | 1 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 8.8/4.4 | 60 | 43 3/16" | 38 | 2" | __ | 0000000 | 00000000 |

| 1/3 | 1,725 | 1 | 4" | 316 Stainless Steel | 32" | 1/2" | 100 | 6.6/3.3 | 60 | 42" | 30 | 2" | __ | 0000000 | 000000 |

Pipe-Mount Air-Powered Mixers for Small Batches

The pipe-clamp connection allows you to quickly raise or lower these mixers to change containers. Also known as direct-drive mixers, they operate at high speeds for rapid turnover. Use them to mix liquids with a viscosity similar to water and light oils. A needle valve allows you to adjust the mixing speed. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Mixer with one propeller comes with four shafts of multiple lengths.

Mixer with two propellers is used for faster and more thorough mixing than mixers with one propeller.

Propellers | Shaft | Air Connection | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | For Pipe OD | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption | O'all Ht. | Wt., lbs. | Each | |

For Thin Liquids | ||||||||||||||||

| 1/2 | 300-1,750 | 1 1/2" | 1 | 4" | 316 Stainless Steel | 12" 16" 20" 24" | 5/8" | 100 | 1/4 | NPT | Female | 25 cfm @ 80 psi | 17 13/16" 21 13/16" 25 13/16" 29 13/16" | 12 | 0000000 | 000000000 |

| 1/2 | 300-1,750 | 1 1/2" | 2 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 1/4 | NPT | Female | 25 cfm @ 80 psi | 37 13/16" | 17 | 0000000 | 00000000 |

Thread-In/Rim-Clamp Air-Powered Mixers for Drums

For reduced vibration and noise, this mixer has a clamp in addition to the thread-in connection. Propellers are collapsible to fit through 55-gallon drums with a NPT opening size of 2, so there's no need to remove the lid. Also known as a direct-drive mixer, it operates at high speeds for rapid turnover. Use it to mix liquids with a viscosity similar to water and light oils. Adjust mixing speed with the needle valve. Mixer has four propellers for fast and thorough mixing. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Propellers | Shaft | Air Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Each | |

For Thin Liquids | |||||||||||||||

| 1 1/2 | 30-3,000 | 4 | 6" | 304 Stainless Steel | 36" | 1/2" | 1/4 | NPT | Female | 60 cfm @ 80 psi | 42" | 19 | 1" | 00000000 | 000000000 |

Rim-Clamp Air-Powered Mixers for Drums

These mixers have collapsible propellers that fit through 55-gallon drums with a NPT opening size of 2, so there's no need to remove the lid. Also known as direct-drive mixers, they operate at high speeds for rapid turnover. Use them to mix liquids with a viscosity similar to water and light oils. Adjust mixing speed with a needle valve. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Mixer with four propellers is for faster and more thorough mixing than mixers with one propeller.

Propellers | Shaft | Air Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption | O'all Ht. | Wt., lbs. | Max. Clamp Opening | Each | |

For Thin Liquids | |||||||||||||||

| 1/2 | 350-1,750 | 1 | 3 3/4" | 316 Stainless Steel | 32" | 5/8" | 1/4 | NPT | Female | 25 cfm @ 80 psi | 38 3/8" | 20 | 5" | 00000000 | 000000000 |

| 1 1/2 | 30-3,000 | 4 | 6" | 304 Stainless Steel | 36" | 1/2" | 1/4 | NPT | Female | 60 cfm @ 80 psi | 46" | 20 | 2" | 00000000 | 00000000 |

| Includes | Each | |

| Body Gasket, Dead End Bearing, Drive End Bearing, Gasket End Cap, Push Pin, Shaft Seal, Vane, Vane Spring | 0000000 | 0000000 |

Rim-Clamp Electric Mixers for Drums

This mixer has a collapsible propeller that fits through 55-gallon drums with a NPT opening size of 2, so there's no need to remove the lid. Also known as a direct-drive mixer, it operates at high speeds for rapid turnover. Use it to mix liquids with a viscosity similar to water and light oils. Propeller is left hand and moves clockwise when viewed from above to direct flow downward for efficient mixing. Motor is totally enclosed fan cooled (TEFC) for use in environments with splashing water and dust.

Propellers | Shaft | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Each | |

120/240V AC Single Phase—Wire Leads | ||||||||||||

For Thin Liquids | ||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 33 1/8" | 5/8" | 8.8/4.4 | 60 | 44 3/4" | 37 | 0000000 | 000000000 |

Hazardous Location Rim-Clamp Electric Mixers for Drums

Motor is UL listed for use in environments with flammable gases and combustible dust. Attach this mixer to the lip of a drum. The propeller is collapsible to fit through 55-gallon drums with a NPT opening size of 2, so there's no need to remove the lid. Also known as a direct-drive mixer, it operates at high speeds for rapid turnover. Use it to mix liquids with a viscosity similar to water and light oils. Propeller is left hand and moves clockwise when viewed from above to direct flow downward for efficient mixing.

Propellers | Shaft | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current, A | Frequency, Hz | O'all Ht. | Wt., lbs. | Environmental Rating | Each | |

120/240V AC Single Phase—Wire Leads | |||||||||||||

For Thin Liquids | |||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 33 1/8" | 5/8" | 8.8/4.4 | 60 | 47 1/2" | 50 | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 000000000 |

Air-Powered Mixers for Intermediate Bulk Containers

The propellers on these air-powered mixers fit through standard intermediate bulk containers. Mixers come mounted to a bracket that centers the propeller in your container to prevent damage from the blades. Propellers are left hand and move clockwise when viewed from above to direct flow downward for efficient mixing.

Mixers with two propellers are used for faster mixing than mixers with one propeller.

Mixers for thin liquids are for liquids with a viscosity similar to water and light oils. Also known as direct-drive mixers, they operate at high speeds for rapid turnover.

Mixers for thick liquids are for liquids with a viscosity similar to honey and molasses. Also known as gear-drive mixers, they turn propellers at low speeds.

Mixers with forklift entry can be moved from one container to the next with a forklift.

Mixers | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | Replacement Air Motors | ||||||||||||||

| hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption | O'all Ht. | Wt., lbs. | Mount Type | Each | Each | ||

For Thin Liquids | |||||||||||||||||

With Forklift Entry | |||||||||||||||||

| 1/2 | 600-2,000 | 1 | 5" | 316 Stainless Steel | 32" | 1" | 1/4 | NPT | Female | 45 cfm @ 80 psi | 38" | 30 | Clamp On | 0000000 | 000000000 | 0000000 | 0000000 |

| 1 | 600-2,000 | 1 | 6" | 316 Stainless Steel | 32" | 1" | 1/4 | NPT | Female | 45 cfm @ 80 psi | 38" | 30 | Clamp On | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 600-2,000 | 2 | 6" | 316 Stainless Steel | 35" | 1" | 1/2 | NPT | Male | 80 cfm @ 80 psi | 43" | 41 | Clamp On | 0000000 | 00000000 | 0000000 | 000000 |

Without Forklift Entry | |||||||||||||||||

| 4 | 300-3,000 | 2 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Male | 110 cfm @ 80 psi | 43" | 56 | Clamp On | 0000000 | 00000000 | 000000 | 00 |

For Thick Liquids | |||||||||||||||||

With Forklift Entry | |||||||||||||||||

| 1/2 | 10-350 | 1 | 10" | 316 Stainless Steel | 35" | 1" | 1/4 | NPT | Male | 22 cfm @ 80 psi | 47" | 77 | Clamp On | 000000 | 00000000 | 0000000 | 000000 |

| 1 | 10-350 | 1 | 12" | 316 Stainless Steel | 35" | 1" | 1/4 | NPT | Male | 22 cfm @ 80 psi | 47" | 77 | Clamp On | 000000 | 00000000 | 0000000 | 000000 |

| 2 | 10-350 | 2 | 12" | 316 Stainless Steel | 35" | 1" | 1/2 | NPT | Male | 70 cfm @ 80 psi | 49" | 86 | Clamp On | 000000 | 00000000 | 0000000 | 000000 |