About Backflow-Prevention Valves

More

Threaded Check Valves

These valves open to allow flow in one direction and close when flow stops or reverses.

Nickel-plated brass valves are more corrosion resistant than plain brass or bronze valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Spring Material: See table

- Seal Material: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Spring Material | Seal Material | End-to-End Lg. | For Use With | Each | |

Brass Body—Buna-N Rubber Spring-Loaded Piston | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 69 | 400 psi @ 70° F | __ | 2 | 35° to 225° | 302 Stainless Steel | Buna-N Rubber | 6 13/16" | Air; Argon; Helium; Krypton; Neon; Oil; Water; Xenon | 0000000 | 0000000 |

Brass Body—304 Stainless Steel Spring-Loaded Piston | |||||||||||

| 2 1/2 | 77 | 400 psi @ 70° F | 125 psi @ 350° F | 2 | 35° to 350° | 302 Stainless Steel | 303 Stainless Steel | 6 13/16" | Air; Argon; Helium; Krypton; Neon; Oil; Steam; Water; Xenon | 0000000 | 000000 |

Nickel-Plated Brass Body—304 Stainless Steel Spring-Loaded Piston | |||||||||||

| 2 1/2 | 77 | 400 psi @ 70° F | 125 psi @ 350° F | 2 | 35° to 225° | 302 Stainless Steel | 303 Stainless Steel | 6 13/16" | Air; Argon; Helium; Krypton; Neon; Oil; Steam; Water; Xenon | 0000000 | 000000 |

High-Flow Threaded Check Valves

To achieve the maximum possible flow, internal components are designed to reduce flow resistance. These valves open to allow flow in one direction and close when flow stops or reverses. A removable cap provides easy access to internal components for maintenance.

316 stainless steel valves are more corrosion resistant than bronze valves.

Repair kits include everything you need to rebuild the valve.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Argon, Helium, Krypton, Neon, Steam, Water, Xenon

- Disc Material: See table

- Seal Material: See table

Valves | Repair Kits | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Disc Material | Seal Material | End-to-End Lg. | Features | Each | Each | ||

NPT Female × NPT Female—Pressure Class 125 | |||||||||||||

| 2 1/2 | 192 | 200 psi @ 150° F | 125 psi @ 353° F | 0.5 | -20° to 405° | Bronze | Bronze | 6" | Removable Cap | 0000000 | 0000000 | 0000000 | 0000000 |

NPT Female × NPT Female—Pressure Class 150 | |||||||||||||

| 2 1/2 | 150 | 300 psi @ 150° F | 150 psi @ 366° F | 0.5 | -20° to 405° | Bronze | Bronze | 7" | Removable Cap | 0000000 | 000000 | 000000 | 00 |

NPT Female × NPT Female—Pressure Class 200 | |||||||||||||

| 2 1/2 | 150 | 400 psi @ 150° F | 200 psi @ 388° F | 0.5 | -20° to 550° | Bronze | Bronze | 7" | Removable Cap | 0000000 | 000000 | 00000000 | 00000000 |

NPT Female × NPT Female—Pressure Class 300 | |||||||||||||

| 2 1/2 | 150 | 600 psi @ 150° F | 300 psi @ 422° F | 0.5 | -20° to 550° | Bronze | Bronze | 7" | Removable Cap | 0000000 | 00000000 | 00000000 | 00000000 |

- For Use With: Air, Steam, Water

- Disc Material: 316 Stainless Steel

- Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | Features | Each | |

NPT Female × NPT Female—Pressure Class Not Rated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 660 | 200 psi @ 70° F | 150 psi @ 350° F | 0.5 | -20° to 400° | 6 1/8" | Removable Cap | 00000000 | 0000000 |

High-Temperature Threaded Check Valves

Size Bronze Valves and

303 Stainless Steel Valves

The heat-resistant rubber seal withstands temperatures up to 500° F. These valves open to allow flow in one direction and close when flow stops or reverses.

Use bronze valves when corrosion is not a concern.

Repair kits include everything you need to rebuild the valve.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

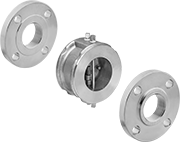

Flange-Mount Check Valves

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Disc Material: Bronze

- Seal Material: Buna-N Rubber

Sandwich these valves between two ANSI flanges for backflow prevention at a fraction of the weight of flanged check valves and a reduced pipeline footprint. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

Cast Iron Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 2 1/2 | 100 | 200 psi @ 70° F | 1.25 | -20° to 250° | 2 1/8" | 125 | 0000000 | 000000 |

Socket-Connect Check Valves

- For Use With: Argon, Helium, Krypton, Neon, Steam, Water, Xenon

- Disc Material: 316 Stainless Steel

- Seal Material: PTFE Plastic

Insert unthreaded pipe into the socket ends and weld to create a permanent, leak-tight connection. These valves open to allow flow in one direction and close when flow stops or reverses. The valve body is 316 stainless steel for excellent corrosion resistance. A removable cap provides easy access to internal components for maintenance.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | Features | Each | |

316 Stainless Steel Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | ||||||||||

| 2 1/2 | 280 | 200 | 200 psi @ 70° F | 150 psi @ 350° F | 0.5 | -20° to 400° | 6 1/8" | Removable Cap | 0000000 | 0000000 |

Flanged Check Valves

- For Use With: Air, Steam, Water

- Disc Material:

Pipe Size 4 and smaller: Bronze

Pipe Size 5 and larger: Iron - Seal Material: Bronze

Bolt these valves to ANSI flanges. They open to allow flow in one direction and close when flow stops or reverses. All have a removable cap that provides easy access to internal components for maintenance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure | Temperature Range, °F | End-to-End Lg. | Flange OD | No. of Bolt Holes | Bolt Hole Size | Bolt Circle Dia. | Bolts Included | Includes | Each | |

Cast Iron Body | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | |||||||||||||||

| 2 1/2 | 193 | 125 | 200 psi @ 70° F | 125 psi @ 353° F | 1 psi | -20° to 405° | 8 1/2" | 7" | 4 | 5/8" | 5 1/2" | No | Removable Cap | 0000000 | 0000000 |

Heavy Duty Threaded Check Valves for Drinking Water

- For Use With: Drinking Water

- Piston Material: Polyetherimide Plastic

- Spring Material: 302 Stainless Steel

- Seal Material: Buna-N Rubber

For more durability than plastic, these valves have a metal body. They meet NSF/ANSI 61 for drinking water service. All open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | Each | |

Brass Body | |||||||

|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||

| 2 1/2 | 98.4 | 400 psi @ 180° F | 0.5 | 10° to 210° | 4 3/8" | 0000000 | 0000000 |

Flange-Mount Check Valves for Oil and Fuel

- For Use With: Butane, Diesel Fuel, Fuel Oil, Gasoline, Kerosene, Natural Gas, Oil, Propane

- Disc Material: 316 Stainless Steel

- Seal Material: 316 Stainless Steel

Install these valves between ANSI flanges. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses. Body is 316 stainless steel for excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

316 Stainless Steel Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 2 1/2 | 90 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 2 5/8" | 150, 300, 600 | 0000000 | 0000000 |