About Roller Chain and Sprockets

More

Sprockets for Triple-Strand ANSI Roller Chain

Three rows of teeth make these sprockets compatible with triple-strand ANSI roller chain. The teeth are hardened steel, so they resist wear better and last longer than standard steel teeth. For a custom fit on your shaft, machine these sprockets to your exact specifications. They come machined to the shaft diameter listed and are machinable up to the maximum shaft diameter size.

For technical drawings and 3-D models, click on a part number.

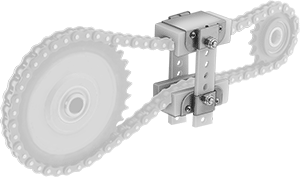

Floating Roller Chain Tensioners

Mount these tensioners directly onto your chain drive. They have adjustable straps that take up slack and apply constant tension. Because they engage with the side plates instead of the rollers, they increase the life of your roller chain.

UHMW tensioners are stronger and more durable than PTFE tensioners.

PTFE tensioners handle temperatures up to 450° F, more than twice as high as UHMW and titanium models.

Titanium tensioners stand up to harsh and dirty environments. They're stronger and more durable than plastic tensioners. And with a low coefficient of friction, they work with chain that has little or no lubrication.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Roller Chain Trade Size | For Roller Chain Strand Type | Ht. | Wd. | Dp. | Housing Material | Strap Material | Max. Temperature, ° F | Each | |

For ANSI Roller Chain | |||||||||

UHMW Plastic | |||||||||

| 60, 35-2, 40-2, 35-3 | Single, Double, Triple | 12" | 4" | 3 1/8" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 0000000 |

PTFE Plastic | |||||||||

| 60, 35-2, 40-2, 35-3 | Single, Double | 12" | 4" | 3 1/8" | 304 Stainless Steel | Galvanized Steel | 450° | 00000000 | 000000 |

Titanium | |||||||||

| 60, 35-2, 40-2, 35-3 | Single, Double, Triple | 12" | 4" | 3 1/8" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |