About Composites

More

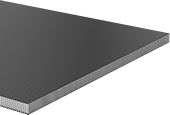

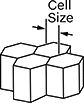

Composite Fiber Aluminum Honeycomb Panels

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

An aluminum honeycomb core sandwiched between carbon fiber keeps these sheets strong yet lightweight. The carbon fiber facing gives you the same strength as a honeycomb panel that's entirely made from aluminum but without the weight. Compared to aramid honeycomb panels, these panels have better shear strength. These panels are often used in the automotive and aerospace industry in place of solid aluminum sheets thanks to their high strength-to-weight ratio.

For technical drawings and 3-D models, click on a part number.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Face Thick. | Temperature Range, °F | Each | |

12" × 12" | ||||||

|---|---|---|---|---|---|---|

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 0000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 24" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 48" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

Ultra-Strength Lightweight Carbon Fiber Square Tubes

- Color: Black

- Temperature Range: 0° F to 250° F

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Mount these lightweight tubes to flat surfaces in place of aluminum to create structural frames, machinery components, and robotics. This carbon fiber weighs less yet is almost as rigid as aluminum. Adopted by the aerospace industry, carbon fiber is known for its balance of weight and strength. And since it's lightweight, it reduces the wear and stress on motorized parts, extending the life of machines.

These tubes have layers that alternate fibers in three directions, so they spread out their strength and resist crushing along the entire tube. They are checked, so they won’t fray or splinter when cut, making them easy to machine. They have the classic carbon-fiber look.

For technical drawings and 3-D models, click on a part number.

Outside | Inside | 12" Lg. | 32" Lg. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wd. | Wd. Tolerance | Ht. | Ht. Tolerance | Wd. | Ht. | Each | Each | ||

0.04" Wall Thick. (-0.02" to 0.02") | |||||||||

| 0.83" | -0.02" to 0.02" | 0.83" | -0.02" to 0.02" | 3/4" | 3/4" | 0000000 | 000000 | 0000000 | 0000000 |

| 1.08" | -0.02" to 0.02" | 1.08" | -0.02" to 0.02" | 1" | 1" | 0000000 | 00000 | 0000000 | 000000 |

0.06" Wall Thick. (-0.02" to 0.02") | |||||||||

| 1.37" | -0.02" to 0.02" | 1.37" | -0.02" to 0.02" | 1 1/4" | 1 1/4" | 0000000 | 00000 | 0000000 | 000000 |

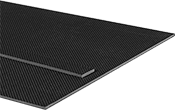

Ultra-Strength Lightweight Carbon Fiber Sheets and Bars

- Color: Black

- Temperature Range: See table

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Known for its use in the aerospace industry, where a balance of weight and strength is critical, carbon fiber is now often machined into panels for structural framing, machinery components, and robotics. Use it in place of aluminum to reduce your application's weight without sacrificing much rigidity. Because these sheets and bars are lightweight, they reduce wear and stress on motorized parts, increasing the life of machinery.

Sheets and checked bars have layers that alternate fibers in two directions, so they spread out their strength across the entire sheet or bar. They have more structural integrity compared to plain bars.

Checked carbon fiber is easy to machine and will not fray or splinter when cut. It has the classic carbon-fiber look. Glossy carbon fiber can be sanded for a matte finish or to prep it for painting.

For technical drawings and 3-D models, click on a part number.

| Thick. | Thick. Tolerance | Appearance | Min. Temp. | Max. Temp., °F | Each | |

6" × 6" | ||||||

|---|---|---|---|---|---|---|

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 00000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 3/8" | -0.018" to 0.018" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/2" | -0.025" to 0.025" | Checked, Glossy | Not Rated | 180° | 00000000 | 00000 |

| 3/4" | -0.037" to 0.037" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 1" | -0.05" to 0.05" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

6" × 12" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 00000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 3/8" | -0.018" to 0.018" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/2" | -0.025" to 0.025" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

12" × 12" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 3/8" | -0.018" to 0.018" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/2" | -0.025" to 0.025" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 3/4" | -0.037" to 0.037" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 1" | -0.05" to 0.05" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

12" × 24" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

12" × 36" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 3/8" | -0.018" to 0.018" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

12" × 48" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

24" × 24" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 3/16" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/2" | -0.025" to 0.025" | Checked, Glossy | Not Rated | 180° | 00000000 | 00000000 |

| 3/4" | -0.037" to 0.037" | Checked, Glossy | Not Rated | 180° | 00000000 | 00000000 |

24" × 48" | ||||||

| 1/32" | -0.003" to 0.003" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 0000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000000 |

| 3/8" | -0.018" to 0.018" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000000 |

36" × 36" | ||||||

| 1/16" | -0.004" to 0.004" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 1/8" | -0.006" to 0.006" | Checked, Glossy | Not Rated | 180° | 00000000 | 000000 |

| 1/4" | -0.008" to 0.008" | Checked, Glossy | Not Rated | 180° | 0000000 | 00000000 |

Ultra-Strength Lightweight Carbon Fiber Sheets with Foam Core

- Color: Black

- Temperature Range: 0° F to 250° F

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

A layer of foam is sandwiched between two pieces of carbon fiber to make these sheets even lighter than standard carbon fiber sheets. Carbon fiber is the strongest composite we offer. It’s comparable in strength to 6061 aluminum and is often used to build frames and structures.

For technical drawings and 3-D models, click on a part number.

12" × 12" | ||||

|---|---|---|---|---|

| Thickness | Thick. Tolerance | Appearance | Each | |

| 1/4" | -0.02" to 0.02" | Checked | 0000000 | 0000000 |

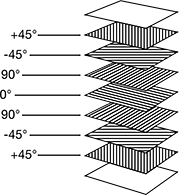

Distortion-Resistant Ultra-Strength Lightweight Carbon Fiber Sheets

- Color: Black

- Maximum Temperature: 180° F

- Tensile Strength: Not Rated

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

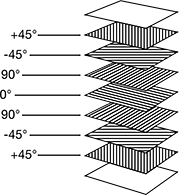

Layers of fibers alternating in four directions makes this carbon fiber stiff at the corners and edges, so it stands up to twisting forces. It also gives you the same stiffness as standard carbon fiber but in a thinner sheet, reducing the overall weight of your application. It's ideal for thin, strong parts—often substituted for aluminum because it's lighter in weight yet almost as rigid.

A checked pattern keeps the fibers from splintering when cut and gives these sheets the classic carbon fiber look. They're glossy but can be sanded for a matte finish.

For technical drawings and 3-D models, click on a part number.

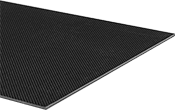

Rigid Ultra-Strength Lightweight Carbon Fiber Sheets

- Color: Black

- Maximum Temperature: 180° F

- Tensile Strength: 125,000-150,000 psi (Excellent)

- Impact Strength: Not Rated

- Hardness Rating: Not Rated

- For Use Outdoors: No

Almost as stiff as steel and a fraction of the weight, these carbon fiber sheets are often used for structural framing, machinery components, and robotics. Known for its use in the aerospace industry—where a balance of weight and strength is critical—carbon fiber is lightweight, so it reduces the stress and wear on motorized parts and extends the life of machinery. These sheets have layers that alternate fibers in two directions, so they resist bending at the edges.

The checked pattern on these sheets gives them a classic carbon-fiber look and makes them easy to machine because the pattern keeps fibers from splintering when the sheets are cut. They are matte, so they do not reflect light and are ready to paint.

For technical drawings and 3-D models, click on a part number.

Impact-Resistant Ultra-Strength Carbon Fiber Sheets with Kevlar Core

- Color: Black

- Temperature Range: -100° to 190° F

- Tensile Strength: 177,000 psi (Excellent)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Often used to build frames and structures, these lightweight sheets combine the strength and stiffness of carbon fiber with the impact resistance of Kevlar. With carbon fiber on the outer layers, these sheets are extremely difficult to bend—they’re nearly as stiff as pure carbon fiber. The carbon fiber layers also provide good strength under tension, comparable to 6061 aluminum. Sandwiched between the carbon fiber layers of these sheets is a Kevlar core. Known for its toughness, the Kevlar core helps prevent sheets from failing under a variety of stresses, such as punctures, cuts, impact, and wear. The Kevlar core also has a lower density than carbon fiber, making these sheets even lighter than sheets made from carbon fiber alone.

Sheets with 0.09 in. thickness have thicker layers of carbon fiber, making them stiffer than those with 0.06 in. thickness.

For technical drawings and 3-D models, click on a part number.

Composite Fiber Aramid Honeycomb Panels

- Face Color: Black

- Temperature Range: -100° to 250° F

- Yield Strength: Not Rated

- For Use Outdoors: No

With an aramid honeycomb core sandwiched between carbon fiber or fiberglass for rigidity, these panels are strong, but lightweight, and won’t conduct heat. Often used as wall panels in structural and insulating applications, they’re a lightweight alternative to solid composite and aluminum honeycomb panels.

Carbon-fiber-faced panels are stronger and more rigid than fiberglass-faced panels, so they resist deforming from bending, twisting, or buckling. They will, however, splinter from high-impact blows. These panels are lighter than fiberglass-faced panels. However, they conduct electricity, so don’t use them around electrical components.

Easy-To-Form Ultra-Strength Chemical-Resistant

PAEK and Carbon Fiber Sheets

- Color: Black

- Maximum Temperature: 500° F

- Tensile Strength:

Bidirectional: 275,550 psi

Quasi-Isotropic: 94,850 psi - Impact Strength: Not Rated

- For Use Outdoors: No

Originally designed for the automotive and aerospace industries, these PAEK and carbon fiber sheets are a substitute for metal because they’re as light as aluminum and as strong as a nickel alloy. Their combination of high strength, light weight, chemical resistance, and thermal properties is unusual for a composite. High tension won’t break them apart and extreme compression won’t shrink or crack them. They’re also stiff and withstand abrasions and dents from heavy loads. Cleaning and degreasing chemicals, such as acetone and isopropyl alcohol, won’t damage them. Unlike most composites, they’re recyclable too.

Form these sheets into the shapes you need using heat and pressure. Compared to PEEK composites, they don’t need as high of a curing temperature to thermoform them, so they save you time and energy. Different from composites made with adhesives and epoxies, which you must machine, layer, and cure, you can repeatedly and quickly heat and form these sheets without hurting their strength or chemical resistance. However, they will soften if the operating temperature exceeds 500° F—a higher maximum temperature than other thermoformable composites.

Quasi-isotropic sheets have extra rigid corners to resist bending and pulling in any direction. Though, they’re not as good at resisting force in one direction as bidirectional sheets.

For technical drawings and 3-D models, click on a part number.

| Thickness | Thickness Tolerance | Appearance | Each | |

12" × 12" | ||||

|---|---|---|---|---|

Quasi-Isotropic | ||||

| 0.044" | -0.004" to 0.004" | Plain | 0000000 | 0000000 |

| 0.088" | -0.009" to 0.009" | Plain | 0000000 | 000000 |

16" × 16" | ||||

Bidirectional | ||||

| 0.066" | -0.007" to 0.007" | Plain | 0000000 | 000000 |

24" × 24" | ||||

Quasi-Isotropic | ||||

| 0.044" | -0.004" to 0.004" | Plain | 0000000 | 00000000 |

| 0.088" | -0.009" to 0.009" | Plain | 0000000 | 00000000 |

32" × 32" | ||||

Bidirectional | ||||

| 0.066" | -0.007" to 0.007" | Plain | 0000000 | 00000000 |

Ultra-Conductive Graphene Sheets

This highly conductive graphene material is often used in electronic devices, such as cell phones, laptop computers, digital cameras, and LEDs. It can be folded without tearing or damaging the sheet and can be cut into smaller pieces with scissors. Thickness, width, and length tolerances are not rated.

For technical drawings and 3-D models, click on a part number.

| Thickness | Thickness Tolerance | Width | Length | Each | |

| 0.001" | Not Rated | 8" | 8" | 000000 | 000000 |

Ultra-Conductive Graphene on Copper Foil

Grown by chemical vapor deposition (CVD) on copper foil, this highly conductive graphene material can be transferred using chemical methods such as polymer-supported metal etching, and mechanical methods such as thermal release tape and direct transfer. This graphene foil is 200 times stronger than steel by weight and is also flexible. It comes taped to the corners of a plastic container in a double vacuum-sealed bag to maintain shelf life. Do not remove the packaging until ready to use. Gently peel the tape or cut the corners of the foil to release. Use rolling blades or precision knives to cut the foil.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.