About Nuts, Materials, and Finishes

More

Steel Snap-In Nuts

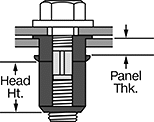

Snap these nuts—also known as cage nuts—into square holes in thin material. They’re often used to mount servers and other equipment in electronics racks. Threads float inside the cage, so you can fasten a bolt at a slight angle to align off-center parts. Mounting legs expand to lock these nuts in place.

Install these nuts by hand, with pliers, or with a snap-in nut installation and removal tool.

Black-phosphate steel nuts are mildly corrosion resistant in dry environments.

Zinc-plated steel nuts resist corrosion in wet environments.

| Thread Size | Thread Pitch | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Pkg. Qty. | Pkg. | |

Black-Phosphate Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 000000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 15 | 000000000 | 0000 |

| 10-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.023" to 0.063" | 0.503" to 0.508" | 0.65" | 0.33" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.093" to 0.126" | 0.588" to 0.593" | 0.87" | 0.41" | 5 | 000000000 | 0000 |

Zinc-Plated Steel | ||||||||

| 6-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 0000 |

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-24 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| 12-24 | __ | 0.063" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.53" | 0.25" | 25 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.028" to 0.056" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.127" to 0.162" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.028" to 0.056" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.127" to 0.162" | 0.503" to 0.508" | 0.7" | 0.3" | 15 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.162" to 0.21" | 0.573" to 0.578" | 0.87" | 0.41" | 1 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.24" to 0.26" | 0.588" to 0.593" | 0.87" | 0.41" | 1 | 000000000 | 0000 |

| 1/2"-13 | __ | 0.093" to 0.126" | 0.588" to 0.593" | 0.87" | 0.41" | 5 | 000000000 | 00000 |

Metric Black-Phosphate Steel | ||||||||

| M8 | 1.25mm | 6.1mm to 6.6mm | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

Metric Zinc-Plated Steel | ||||||||

| M5 | 0.8mm | 0.7mm to 1.6mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 2.4mm to 3.2mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 0.7mm to 1.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 2.4mm to 3.2mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M8 | 1.25mm | 0.7mm to 1.4mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M8 | 1.25mm | 1.5mm to 2.3mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M8 | 1.25mm | 2.4mm to 3.2mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M8 | 1.25mm | 3.2mm to 4.1mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M10 | 1.5mm | 1.5mm to 2.3mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M10 | 1.5mm | 2.4mm to 3.2mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M10 | 1.5mm | 3.2mm to 4.1mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M10 | 1.5mm | 4.1mm to 5mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

Stainless Steel Snap-In Nuts

For excellent corrosion resistance in most environments, these nuts are made of 18-8 stainless steel. Snap them into square holes in thin material, and the mounting legs expand to lock them in place. Also known as cage nuts, the threads float inside the cage, so you can fasten a bolt at a slight angle to align off-center parts. These nuts are often used to mount servers and other equipment in electronics racks. They may be mildly magnetic.

Install these nuts by hand, with pliers, or with a snap-in nut installation and removal tool.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Pitch | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 000000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-24 | __ | 0.093" to 0.126" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-24 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 10-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.49" | 0.25" | 5 | 000000000 | 0000 |

| 10-32 | __ | 0.093" to 0.126" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-32 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.29" | 1 | 000000000 | 0000 |

Metric 18-8 Stainless Steel | ||||||||

| M5 | 0.8mm | 0.7mm to 1.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M5 | 0.8mm | 1.7mm to 2.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M5 | 0.8mm | 2.4mm to 3.2mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| M5 | 0.8mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 0.7mm to 1.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 2.4mm to 3.2mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

Plastic Snap-In Nuts

These nylon nuts are chemical resistant, nonconductive, and lightweight. Inserting a screw pushes the prongs against the panel to secure the nut.

For technical drawings and 3-D models, click on a part number.

| For Screw Size | For Panel Thick. | Square Hole Size | Lg. | Wd. | Ht. | Flange Thick. | Max. Temp., °F | Color | Pkg. Qty. | Pkg. | |

Nylon Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. 4 | 0.031" to 1/8" | 0.275" to 0.285" | 3/8" | 3/8" | 7/32" | 1/16" | 165° | Off-White | 50 | 000000000 | 000000 |

| No. 6 | 0.032" to 0.156" | 0.2" to 0.27" | 7/16" | 5/16" | 5/16" | 1/32" | 165° | Off-White | 50 | 000000000 | 00000 |

| No. 6 | 0.062" to 0.275" | 0.265" to 0.27" | 1/2" | 3/8" | 7/16" | 1/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 6, No. 8 | 0.031" to 1/8" | 0.245" to 0.255" | 3/8" | 3/8" | 9/32" | 1/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 8 | 1/32" to 5/32" | 0.265" to 0.281" | 3/8" | 3/8" | 11/32" | 1/32" | 165° | Off-White | 50 | 000000000 | 00000 |

| No. 8 | 0.078" to 0.175" | 0.285" to 0.295" | 3/8" | 3/8" | 11/32" | 1/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 8, No. 10 | 0.218" to 0.23" | 0.35" to 0.355" | 15/32" | 15/32" | 13/32" | 1/16" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 10 | 1/32" to 5/32" | 0.38" to 0.39" | 5/8" | 5/8" | 5/16" | 3/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 10 | 0.032" to 0.234" | 0.32" to 0.335" | 15/32" | 15/32" | 13/32" | 1/16" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 10 | 0.064" to 0.187" | 0.37" to 0.39" | 19/32" | 19/32" | 9/32" | 3/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 12 | 0.031" to 0.1" | 0.37" to 0.375" | 5/8" | 5/8" | 9/32" | 3/32" | 165° | Off-White | 50 | 000000000 | 00000 |

| For Screw Size | For Panel Thick. | Square Hole Size | OD | Ht. | Flange Thick. | Max. Temp., °F | Color | Pkg. Qty. | Pkg. | |

Nylon Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 6 | 0.032" to 0.15" | 0.28" to 0.285" | 1/2" | 11/32" | 23/32" | 165° | Off-White | 25 | 000000000 | 000000 |

| No. 6 | 0.062" to 0.165" | 0.27" to 0.28" | 3/8" | 5/16" | 3/32" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 8 | 0.031" to 0.156" | 0.275" to 0.29" | 1/2" | 5/16" | 3/8" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 8 | 0.062" to 0.17" | 0.275" to 0.28" | 1/2" | 5/16" | 5/16" | 165° | Off-White | 25 | 000000000 | 00000 |

| No. 10 | 0.031" to 0.16" | 0.305" to 0.31" | 1/2" | 9/32" | 1/32" | 165° | Off-White | 50 | 000000000 | 00000 |

| No. 12 | 0.032" to 1/8" | 0.35" to 0.355" | 17/32" | 9/32" | 1/8" | 165° | Off-White | 25 | 000000000 | 00000 |

| 1/4" | 0.031" to 1/8" | 0.37" to 0.375" | 5/8" | 9/32" | 1 1/16" | 165° | Off-White | 10 | 000000000 | 00000 |

| 1/4" | 1/32" to 5/32" | 0.33" to 0.343" | 9/16" | 11/32" | 1/16" | 165° | Off-White | 25 | 000000000 | 00000 |

| 5/16" | 0.032" to 0.135" | 0.415" to 0.43" | 3/4" | 5/16" | 1/16" | 165° | Off-White | 10 | 000000000 | 00000 |

Easy-to-Install Snap-In Nuts

Pinch the flexible plastic casing of these nuts to add threads to thin metal. Unlike typical rigid snap-in nuts, these squeeze into a square hole from the front or back of your material. Once installed, they stay put. They meet DIN EN 61373, so they’re certified for use in environments with heavy vibration—think a bumpy railcar. GR-63-CORE tested, they’ve also passed earthquake simulations. In your facility, this means you can trust them to hold tight to sensitive equipment, like the servers suspended on your electrical racks.

Also known as cage nuts, they come in two parts—the cage and the nut—that you combine before installation. Threads float inside the cage, so you can fasten a bolt at a slight angle to align with off-center parts.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Pitch, mm | For Panel Thick., mm | Square Hole Size | Wd. | Head Ht. | Case Material | Specifications Met | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M6 | 1 | 1 to 4 | 0.362" to 0.375" | 0.5" | 0.41" | Plastic | DIN EN 61373; GR-63-CORE, Issue 4 | 10 | 000000000 | 000000 |

Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong, permanent hold. They stand up to high torque and pulling force better than rivet nuts.

For the strongest threads, choose steel nuts. Nuts with a steel retainer should be welded to uncoated steel surfaces. Zinc-plated steel nuts resist corrosion in wet environments. Nuts with an aluminum retainer should be welded to aluminum surfaces.

For the most corrosion resistance, choose stainless steel nuts. They have a stainless steel retainer, so they should be welded to stainless steel surfaces.

For technical drawings and 3-D models, click on a part number.

Base | |||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Ht. | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 6-32 | 1 1/2" | 1/2" | 3/64" | 29/64" | 1 | 000000000 | 00000 |

| 8-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 1/4"-28 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 5/16"-24 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-24 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

| 7/16"-14 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

| 1/2"-13 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | |||||||

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 5 | 000000000 | 0000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 5 | 000000000 | 0000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Stainless Steel Nut with Stainless Steel Retainer | |||||||

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 11/32" | 1 | 000000000 | 00000 |

Metric Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong permanent hold. They stand up to high torque and pulling force better than rivet nuts.

Weld steel nuts with a steel retainer to uncoated steel surfaces.

Weld zinc-plated steel nuts with an aluminum retainer to aluminum surfaces. They resist corrosion in wet environments.

For technical drawings and 3-D models, click on a part number.

Thread | Base | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Wd., mm | Thick., mm | Ht., mm | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | ||||||||

| M5 | 0.8 | 38.1 | 12.7 | 1.06 | 8.6 | 5 | 000000000 | 000000 |

| M6 | 1 | 38.1 | 12.7 | 1.06 | 8.6 | 10 | 000000000 | 00000 |

| M8 | 1.25 | 50.8 | 19.8 | 1.27 | 13.7 | 5 | 000000000 | 00000 |

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

| M12 | 1.75 | 58.7 | 23.8 | 1.27 | 20.2 | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | ||||||||

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

Snap-In Nut Installation and Removal Tools

Your fingers will thank you later—these tools compress the legs of snap-in nuts so they’re easy to install and remove. This is especially helpful if you’re installing a bunch back-to-back.

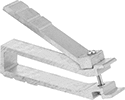

Style A tools work like a shoehorn. Angle one of the nut’s legs into the hole, then hook one of the tool’s prongs under the other leg to pull the nut into place.

Style B tools compress both nut legs simultaneously, so you can pop nuts in or out with a pinch. Simply squeeze the handle like a nail clipper. To grip nuts of different sizes, adjust the screw to open and close the end.

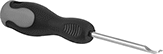

Style C tools are the most ergonomic. Just like a screwdriver, they have a cushion grip and a long handle for leverage. Dip one of the nut’s legs into the hole, then use the tool’s curved lip to tuck in the other leg, pulling the nut into place.

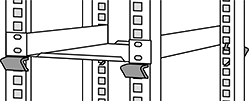

Equipment Installation Supports for Electronics Racks

Shelve your worries about dropping heavy and valuable rack components, from servers to router shelves. These supports create temporary ledges to let equipment—and your arms—rest as you set up your electronics rack. Each pack includes four supports, one to prop up each corner of the equipment. Simply snap them into the rack’s rail just below the level where you want to mount equipment. When you’re done installing, pop them right out.

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Threaded Hole Size | Ht. | Wd. | Dp. | Cap. per Four Supports, lbs. | Component Mount Type | Color | Pkg. | |

Pkg. of 1 (4 Supports Included) | ||||||||

Powder-Coated Steel | ||||||||

| 10-32, 12-24, M5, M6 | 3/4" | 1 1/4" | 1" | 50 | Rails | Gray | 000000000 | 000000 |

Pkg. of 20 (80 Supports Included) | ||||||||

Powder-Coated Steel | ||||||||

| 10-32, 12-24, M5, M6 | 3/4" | 1 1/4" | 1" | 50 | Rails | Gray | 000000000 | 000000 |