How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized and zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size | Plug Construction | Max. Pressure | Material | For Use With | Specifications Met | Each | |

BSPP Male | |||||||

|---|---|---|---|---|---|---|---|

| 5/8 | Hollow | 3,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ISO 1179, ISO 8434-6 | 00000000 | 00000 |

BSPT Male | |||||||

| 5/8 | Solid | 3,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | DIN EN 10226-1, ISO 7-1 | 00000000 | 0000 |

- Temperature Range: -20° to 230° F

| For Pipe Size | Gasket Material | Thickness | Each | |

For BSPP Male | ||||

|---|---|---|---|---|

| 5/8 | Buna-N Rubber | 2.5mm | 00000000 | 00000 |

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Oil

- Maximum Temperature: 140° F

| Pipe Size | Material | Color | Maximum Pressure | Pkg. Qty. | Pkg. | |

BSPP | ||||||

|---|---|---|---|---|---|---|

| 5/8 | Polyethylene Plastic | Red | Not Rated | 10 | 0000000 | 00000 |

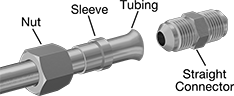

30° Flared Fittings for Steel Tubing

- Specifications Met: See table

Also known as JIS (Japanese Industrial Standard) fittings, these have a 30° flare on one or both ends. Fittings are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 5/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 00000000 | 000000 |

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 5/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 00000000 | 000000 |

Wing Nut Expansion Plugs

Twist the wing nut on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Style A aren’t recommended for pressure testing, so they’re often used as a dust cover. Plugs with a stainless steel plate have excellent corrosion resistance.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Style A | ||||||||

Stainless Steel Plate | ||||||||

| 5/8 | 0.57"-0.67" | 10 | 24 | 1 11/16" | 0° to 175° | Neoprene Rubber | 0000000 | 000000 |

Hex-Nut Expansion Plugs

Tighten the nut on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Plugs with a stainless steel plate have excellent corrosion resistance.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Style B | ||||||||

Stainless Steel Plate | ||||||||

| 5/8 | 0.57"-0.67" | 10 | 24 | 1 11/16" | -40° to 250° | Neoprene Rubber | 0000000 | 000000 |

Quick-Snap Expansion Plugs

Turn the cam handle to expand the seal, then snap the handle down to hold it in place and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Plugs with a stainless steel plate have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Brass Handle | ||||||||

Stainless Steel Plate | ||||||||

| 5/8 | 0.62"-0.67" | 10 | 24 | 1 3/8" | -40° to 250° | Neoprene Rubber | 0000000 | 000000 |

Stainless Steel Handle | ||||||||

Stainless Steel Plate | ||||||||

| 5/8 | 0.62"-0.67" | 10 | 24 | 1 3/8" | -40° to 250° | Neoprene Rubber | 0000000 | 00000 |

Expansion Plugs with Bypass

Use the bypass tube on these plugs to add air, water, and other fluid to your pipeline or to relieve pressure while testing. The seal expands to temporarily close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

For Styles A-E and H-L, twist the wing nut to expand the seal.

Styles E and F have a barbed bypass for quick connections to tubing.

For technical drawings and 3-D models, click on a part number.

For Pipe | Max. Back Pressure | Material | Bypass | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal | For Tube ID | Tube Connection Type | Each | |

Style E | ||||||||||

Stainless Steel Stem | ||||||||||

| 5/8 | 0.60"-0.67" | 10 | 24 | 3 1/2" | -40° to 250° | Neoprene Rubber | 1/4" | Barbed | 0000000 | 0000000 |