How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Metal Round Caps

More durable than plastic caps, these provide the most protection from abrasion and impact.

Steel caps are stronger than aluminum.

Aluminum caps have good corrosion resistance, are lightweight, and are nonmagnetic.

For technical drawings and 3-D models, click on a part number.

Tapered Caps

These flexible plastic caps are tapered to fit a variety of unthreaded and threaded objects.

For technical drawings and 3-D models, click on a part number.

| For OD | For Pipe Size | Inside Ht. | Max. Temp., °F | Color | Pkg. Qty. | Pkg. | |

Flexible Polyethylene Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 5.21"-5.37" | 5 | 7/8" | 150° | Red | 10 | 00000000 | 000000 |

Adhesive-Back Flange Caps

Stick these caps on the raised surfaces of flanges or other flat surfaces for extra protection during transport and storage.

For technical drawings and 3-D models, click on a part number.

| For Pipe Size | For OD | Adhesive Type | Max. Temp., °F | Color | Pkg. Qty. | Pkg. | |

Rigid Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 5 | 7 5/16" | Rubber | 160° | Black | 3 | 0000000 | 000000 |

Hollow Tapered Plugs

The hollow construction allows these plugs to compress for a snug fit in threaded and unthreaded holes of varying diameters. Use the flange to remove them with ease.

For technical drawings and 3-D models, click on a part number.

| For Pipe Size | For ID | Ht. | Flange Dia. | Max. Temp., °F | Hardness | Color | Pkg. Qty. | Pkg. | |

Polyethylene Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For Unthreaded Pipe | |||||||||

| 5 | 4.99"-5.2" | 1" | 5 5/8" | 150° | Durometer 45D | Red | 10 | 0000000 | 000000 |

Low-Pressure Steel Threaded Pipe Flanges

Use these flanges for low-pressure applications in noncorrosive environments. Bolt two flanges of the same size together with a gasket (sold separately) to create an access point within a line.

Reducing flanges allow you to transition your system to a smaller pipe size; attach to a flange with a larger pipe size but with the same flange dimensions.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

NPT: ASME B16.5, ASTM A105, MSS SP-25

BSPT: ASTM A105 - Fittings: Use Class 125 or 150 iron and steel

- Pipe Nipples and Pipe: Use Schedule 40 steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 285 psi @ 72° F | 230 psi @ 300° F | Steel | 000000000 | 000000 |

- For Use With:

1/4 Pipe Size: Air, Natural Gas, Oil, Water

All other sizes: Air, Natural Gas, Oil, Steam, Water - Specifications Met:

1/4 Pipe Size: ASTM A105, MSS SP-6

All other sizes: ASME B16.5, ASTM A105, MSS SP-25, MSS SP-6 - Fittings: Use Class 125 or 150 iron and steel

- Pipe Nipples and Pipe: Use Schedule 40 Steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Flange Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | |||||||||||

| 5 | 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 285 psi @ 72° F | 230 psi @ 300° F | Steel | 0000000 | 0000000 |

FM-Approved Low-Pressure Cast Iron Threaded Pipe Flanges

Suitable for use in fire-protection applications, these flanges are brittle and can be quickly opened with the strike of a sledge hammer. Bolt two flanges of the same size together with a gasket (sold separately) to create an access point within a line. Use in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met:

3/4 Pipe Size: ASME B1.20.1, ASME B16.1, ASTM A126, FM Approved

All other sizes: ASME B1.20.1, ASME B16.1, ASTM A126, FM Approved, UL Listed - Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Class 125 iron and steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000000 |

Low-Pressure Galvanized Steel Threaded Pipe Flanges

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: ASTM A123, ASTM A105, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Fittings: Use Class 125 or 150 galvanized iron and galvanized steel

The galvanized finish on these flanges provides fair corrosion resistance. Also known as Pressure Class 150 flanges, they are for use in low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line.

For technical drawings and 3-D models, click on a part number.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

NPT | |||||||||

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 285 psi @ 72° F | 150 psi @ 300° F | 00000000 | 0000000 |

Medium-Pressure Steel Threaded Pipe Flanges

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 300 or Schedule 80 iron and steel

With better strength than our low-pressure steel flanges, these are for use in medium-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges are also known as Pressure Class 300 or Pressure Class 600 flanges. Use in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

Pressure Class 300 | ||||||||||

| 5 | 11" | 3/4" | 7/8" | 8 | 9 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 0000000 |

Low-Pressure Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line. Flanges are for use with low-pressure applications in noncorrosive environments.

Butt-weld flanges are also known as weld-neck flanges. The flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

Slip-on weld flanges have no internal stop. Slide a pipe through the flange and weld on both sides.

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Cap flanges are also known as blind flanges.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Construction | Max. Pressure | Max. Steam Pressure | Certification | Specifications Met | Each | |

| 5 | 0.258" | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 150 | Seamless | 285 psi @ 72° F | 150 psi @ 300° F | Material Certificate with Traceable Lot Number and Test Report | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: See Table

Bolt Hole | For Fitting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Max. Pressure | Max. Steam Pressure | Schedule | Material | Certification | Specifications Met | Each | |

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 150 | 285 psi @ 72° F | 150 psi @ 300° F | 40 | Iron, Steel | Material Certificate with Traceable Lot Number and Test Report | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 285 psi @ 72° F | 150 psi @ 300° F | ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: MSS SP-25, ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 285 psi @ 72° F | 150 psi @ 300° F | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

| 5 | 10" | 3/4" | 7/8" | 8 | 8 1/2" | 150 | 285 psi @ 72° F | 150 psi @ 300° F | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

High-Pressure Steel Unthreaded Pipe Flanges

Forged for extra strength, these heavy duty flanges can withstand high-pressure applications. Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line.

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides.

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting.

Cap flanges are also known as blind flanges.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | |||||||||||

| 5 | 0.375" | 11" | 3/4" | 7/8" | 8 | 9 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | ||||||||||

| 5 | 11" | 3/4" | 7/8" | 8 | 9 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

Pressure Class 300 | |||||||||||

| 5 | 11" | 3/4" | 7/8" | 8 | 9 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | ASME B16.5, ASTM A105 | 00000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | ||||||||||

| 5 | 11" | 3/4" | 7/8" | 8 | 9 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 0000000 |

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

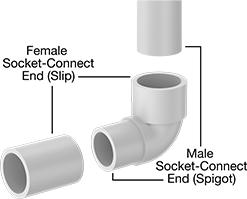

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: See table

For Flange | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Material | Schedule | Material | Each | |

White | ||||||

| 5 | 3" | PVC Plastic | 40 | PVC Plastic | 00000000 | 000000 |

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe–they have thicker, stronger walls than standard-wall fittings so they can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

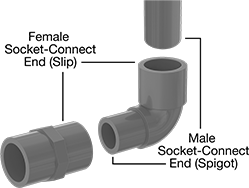

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 5 | 2 5/8" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

Thick-Wall Plastic Pipe Flanges for Water

- For Use With: Drinking Water, Water

- Pressure Class: 150

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Fittings: Use Schedule 80 PVC Plastic

Also known as Pressure Class 150 flanges, these flanges have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. They meet NSF/ANSI 61 for drinking water. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. All are PVC, which has good corrosion resistance. They meet ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

Cap flanges are also known as blind flanges.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. | Bolt Circle Dia. | Material | Color | Each | |

| 5 | 10 1/16" | 3/4" | 7/8" | 8 | 8 1/2" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

Low-Pressure Clamp-On Connectors for Drain, Waste, and Vent

To make installing and maintaining systems easy, these connectors come with clamps that form a strong seal on pipe and fittings once tightened.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: -40° to 120° F

- Specifications Met: ASTM D5926

- For Pipe Material: Cast Iron, Steel, Copper, Lead, PVC Plastic, CPVC Plastic, Polyethylene Plastic

| For Pipe OD | For Pipe Size | Max. Pressure | Material | Clamp Material | Flexibility | Each | |

Pipe | |||||||

|---|---|---|---|---|---|---|---|

| 5.6" | 5 | 4 psi @ 72° F | PVC Plastic | 300 Series Stainless Steel | Flexible | 00000000 | 000000 |

Wing Nut Expansion Plugs

Twist the wing nut on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Expansion Plugs with Bypass

Use the bypass tube on these plugs to add air, water, and other fluid to your pipeline or to relieve pressure while testing. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

For Pipe | Max. Back Pressure | Material | Bypass | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal | Bypass Cap | Pipe Size | Thread Type | Gender | Each | |

Style C | ||||||||||||

Iron Stem | ||||||||||||

| 5 | 4.50"-5.00" | Not Rated | 23 | 12 5/8" | 30° to 150° | Natural Rubber | Metal | 1/2 | NPT | Male | 0000000 | 000000 |

Style D | ||||||||||||

Plastic Stem | ||||||||||||

| 5 | 4.72"-5.37" | 12 | 27 | 4 1/2" | -40° to 180° | Natural Rubber | Plastic | 1/2 | NPT | Male | 0000000 | 00000 |

Air-Inflatable Plugs

Conform to wide and out-of-round pipes with these inflatable plugs. Also known as pneumatic plugs, they're designed for temporary seals since they can lose pressure over time. Inflate with a hand pump (sold separately); an air compressor may overinflate the plug and cause damage. Tether the plugs using either the eyebolt or chain/ring so they don't get lost or stuck in your pipes. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

For Pipe | Deflated | Max. Back Pressure | Material | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | ID | Dia. | Ht. | Air, psi | Water, ft. of head | Required Inflation Pressure, psi | Temp. Range, °F | Seal | Chain/Ring | Each | |

| 5 | 4.60"-5.25" | 4 1/2" | 7 3/4" | 13 | 30 | 30 | -20° to 125° | Natural Rubber | Zinc-Plated Steel | 0000000 | 0000000 |

Drain Pipe Plugs

Seal unthreaded pipe ends with these plugs. They come with a band that clamps over the outside wall of your pipe and tightens with a screwdriver.

Plugs with a faucet let you easily direct flow and drainage in your system.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | OD | Water, ft. of head | Air | Temp. Range | Material | Clamp Material | Each | |

| 5 | 5.30"-5.62" | 10 | Not Rated | Not Rated | Neoprene Rubber | Stainless Steel | 0000000 | 000000 |

For Pipe | Max. Back Pressure | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | OD | Water, ft. of head | Air | Temp. Range | Material | Clamp Material | Faucet Material | For Hose Size | Handle Style | Each | |

| 5 | 5.25"-5.61" | Not Rated | Not Rated | -40° F to 180° F | Neoprene Rubber | Stainless Steel | Brass | 3/4 | Wheel | 00000000 | 000000 |

Cleanout Plugs

Close off your drain cleanout pipe with these threaded plugs. Note: If you do not know your pipe size, measure the OD of your existing cleanout plug or the ID of your cleanout fitting and match to the value listed.