About Wire and Cable

More

Abrasion-Resistant Cable

- Use For:

Unshielded: Motors, Power Supply

Shielded: Motors, Power Supply, Interference Shielding - Flexible

- Temperature Range: -20° to 190° F

- Insulation:

Outer: Polyurethane Rubber

Inner: PVC Plastic

A thick insulation resists cuts and abrasion, so this cable can be pulled over rough surfaces without damaging the wires inside. Made of polyurethane rubber, the insulation also resists chemicals, moisture, oil, solvents, and water. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Use unshielded cable in applications where signal interference is not a concern.

Shielded cable has a layer of foil that blocks signal interference from nearby equipment and devices. It has an uninsulated ground wire that is not counted in the number of wires.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wire Ga. | No. of Wires | Cable AWG | Current | OD | Outer Insulation Color | Inner Insulation Color | Features | Specifications Met | Length, ft. | 1-99 | 100-Up | |

Unshielded Stranded Wire | ||||||||||||

300V AC | ||||||||||||

| 24 | 2 | 24/2 | 2.3 A @ 86° F | 0.16" | Black | Black, Brown | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 22 | 2 | 22/2 | 3.4 A @ 86° F | 0.17" | Black | Black, Brown | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 0000 | 0000 | |

| 20 | 2 | 20/2 | 5.6 A @ 86° F | 0.21" | Black | Black, Red | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 0000 | 0000 | |

| 18 | 2 | 18/2 | 7.9 A @ 86° F | 0.23" | Black | Black, Red | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 0000 | 0000 | |

| 18 | 4 | 18/4 | 6.3 A @ 86° F | 0.26" | Black | Black, Green, Red, White | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 0000 | 0000 | |

| 18 | 6 | 18/6 | 6.3 A @ 86° F | 0.31" | Black | Black, Blue, Green, Orange, Red, White | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 18 | 15 | 18/15 | 3.9 A @ 86° F | 0.43" | Black | Beige, Black, Blue, Brown, Gray, Green, Green/Red, Orange, Pink, Purple, Red, Red/Black, White, Yellow, Yellow/Red | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 16 | 2 | 16/2 | 11.3 A @ 86° F | 0.25" | Black | Black, Red | __ | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 0000 | 0000 | |

Shielded Stranded Wire | ||||||||||||

300V AC | ||||||||||||

| 22 | 6 | 22/6 | 2.7 A @ 86° F | 0.22" | Black | Black, Brown, Green, Orange, Red, Yellow | Uninsulated Ground Wire | UL Recognized Component, C-UL Recognized Component, UL 2556 VW-1 | 0000000 | 00000 | 0000 | |

Corrosion-Resistant Cable

- Use For: Boats, Motors, Panel and Equipment (Hook-Up), Power Supply

- Flexible

- Temperature Range: -40° to 230° F

- Insulation:

Outer: Chlorinated Polyethylene Plastic

Inner: See table

The chlorinated polyethylene insulation resists corrosive chemicals and salt water, and the wires are tin plated for corrosion resistance. This cable also withstands oil and solvents. It’s rated UL 1309 for use as marine shipboard cable.

Cable with braided bronze armor has excellent protection against abrasion and other damage.

Per Ft. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wire Ga. | No. of Wires | Cable AWG | Current | OD | Outer Insulation Color | Inner Insulation Color | Specifications Met | Length, ft. | 1-99 | 100-Up | |

Stranded Wire with Polyolefin Plastic Inner Insulation | |||||||||||

600V AC | |||||||||||

| 16 | 3 | 16/3 | 18 A @ 86° F | 0.37" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 16 | 4 | 16/4 | 14 A @ 86° F | 0.4" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 14 | 3 | 14/3 | 20 A @ 86° F | 0.4" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 14 | 4 | 14/4 | 16 A @ 86° F | 0.44" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 12 | 3 | 12/3 | 25 A @ 86° F | 0.45" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 12 | 4 | 12/4 | 20 A @ 86° F | 0.49" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 10 | 3 | 10/3 | 35 A @ 86° F | 0.49" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 10 | 4 | 10/4 | 28 A @ 86° F | 0.55" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 8 | 4 | 8/4 | 40 A @ 86° F | 0.7" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 6 | 4 | 6/4 | 52 A @ 86° F | 0.79" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 4 | 4 | 4/4 | 68 A @ 86° F | 1.04" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 2 | 4 | 2/4 | 92 A @ 86° F | 1.19" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

Stranded Wire with Polyolefin Plastic, Braided Bronze Armor Inner Insulation | |||||||||||

600V AC | |||||||||||

| 16 | 3 | 16/3 | 18 A @ 86° F | 0.52" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 16 | 4 | 16/4 | 14 A @ 86° F | 0.58" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 14 | 3 | 14/3 | 20 A @ 86° F | 0.58" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 14 | 4 | 14/4 | 16 A @ 86° F | 0.62" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 12 | 3 | 12/3 | 25 A @ 86° F | 0.63" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 12 | 4 | 12/4 | 20 A @ 86° F | 0.67" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 0000 | 0000 | |

| 10 | 3 | 10/3 | 35 A @ 86° F | 0.67" | Black | Black, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 0000 | |

| 10 | 4 | 10/4 | 28 A @ 86° F | 0.73" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 0000 | |

| 8 | 4 | 8/4 | 40 A @ 86° F | 0.92" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 6 | 4 | 6/4 | 52 A @ 86° F | 1.02" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 4 | 4 | 4/4 | 68 A @ 86° F | 1.26" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

| 2 | 4 | 2/4 | 92 A @ 86° F | 1.42" | Black | Black, Green, Red, White | UL Listed, UL 1309, CSA Certified | 0000000 | 00000 | 00000 | |

Servomotor Continuous-Flex Cable

- Use For: Automation, Continuous Motion, Interference Shielding, Motors

- Continuous Flex

- Temperature Range: -40° to 175° F

- Insulation:

Outer: Polyurethane Rubber

Inner: Polypropylene Plastic

Connect servocontrollers and servomotors in automated equipment and on assembly lines. This cable withstands continuous motion without degrading data or signal transmission. The polyurethane rubber insulation resists abrasion and oil. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Cable with power wires sends electricity to run a servomotor.

Cable with signal wires is also known as feedback cable. It sends and receives signals between a servomotor and a PLC.

Cable with power and signal wires sends data such as positioning information from a servomotor to a controller. It has four power wires and two pairs of signal wires.

Shielded cable has a layer of braid that blocks signal interference from nearby equipment and devices. Double shielded cable has a layer of braid and foil shielding for better protection against signal interference than braid alone. Use it in environments with high signal distortion, such as near transformers, generators, and heavy duty motors.

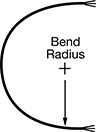

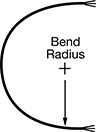

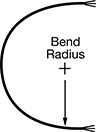

Bend radius is the point to which the cable will bend without being damaged. It is measured from the center of the bend to the edge of the cable. The smaller the measurement, the tighter the bend.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Wires | Wire Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | Length, ft. | 1-49 | 50-Up | |

Double Shielded—1,000V AC | ||||||||||||

| 4 | 14 | 14/4 | 15 A @ 86° F | 0.42" | 3.15" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 4 | 12 | 12/4 | 20 A @ 86° F | 0.47" | 3.53" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 0000 | |

| 4 | 10 | 10/4 | 30 A @ 86° F | 0.57" | 4.28" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| No. of Wires | Wire Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | 5 ft. | 10 ft. | 20 ft. | 30 ft. | 50 ft. | |

Shielded—30V AC/45V DC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 26 | 26/8 | 0.7 A @ 86° F | 0.25" | 2.17" | Green | Black, Blue, Brown, Green, Orange, Purple, Red, Yellow | UL Recognized Component, UL 2556 VW-1 | 0000000 | |||||

| 8 | 24 | 24/8 | 1.4 A @ 86° F | 0.29" | 1.87" | Green | Blue, Brown, Gray, Green, Pink, Red, White, Yellow | UL Recognized Component, UL 2556 VW-1 | 0000000 | |||||

Power Wire | Signal Wire | Per Ft. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Ga. | Cable AWG | No. of | Ga. | Cable AWG | No. of | Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | Length, ft. | 1-49 | 50-Up | |

Double Shielded—1,000V AC | ||||||||||||||||||

| 4 | 14 | 14/4 | 4 | 18 | 18/4 | __ | __ | __ | 15 A @ 86° F | 0.57" | 4.28" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 000000 | 000000 | |

| 4 | 12 | 12/4 | 2 | 18 | 18/2 | 2 | 16 | 16/2 | 20 A @ 86° F | 0.64" | 4.8" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 4 | 10 | 10/4 | 2 | 18 | 18/2 | 2 | 16 | 16/2 | 30 A @ 86° F | 0.71" | 5.33" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

Variable-Frequency Drive Motor Cable

This cable is used in variable-frequency drive motors. It has a layer of braid and foil shielding that provides excellent protection against signal interference caused by voltage fluctuations and current spikes. The industry designation is WTTC, so it can be installed in cable trays or raceway in a wind turbine generator. It’s flame rated FT4 to meet requirements for preventing the spread of flames based on a timed test with material mounted to a vertical tray. The insulation resists oil.

Cable with power wires sends electricity to run a motor. Cable with power and signal wires has an individually shielded pair of wires that connect to a brake or temperature sensor, reducing the number of cables used in areas with limited space.

Cable with an uninsulated ground wire has an additional uninsulated ground wire you can use to ground the cable’s foil shielding. Also known as a drain wire, it isn’t counted in the cable’s number of wires. Cable with three uninsulated ground wires pairs a ground wire with each power wire, so you can create multiple circuits from the same cable. These wires aren’t counted in the cable’s number of wires.

MSHA accepted cable meets Mine Safety and Health Administration (MSHA) standards for material quality.

For technical drawings and 3-D models, click on a part number.

- Use For: Motors, Interference Shielding

- Flexible

- Temperature Range: -40° to 220° F

- Inner Insulation: Nylon Plastic, PVC Plastic

Power Wire | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Ga. | Cable AWG | Current | OD | Outer Insulation Color | Inner Insulation Color | Industry Designation | Features | Certification | Length, ft. | 1-99 | 100-Up | |

Double Shielded—1,000V AC/1,500V DC | |||||||||||||

| 4 | 18 | 18/4 | 7 A @ 86° F | 0.39" | Black | Black | WTTC | __ | MSHA Accepted | 0000000 | 00000 | 00000 | |

| 4 | 16 | 16/4 | 10 A @ 86° F | 0.46" | Black | Black, Green/Yellow | WTTC | Uninsulated Ground Wire | MSHA Accepted | 0000000 | 0000 | 0000 | |

| 4 | 14 | 14/4 | 15 A @ 86° F | 0.52" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 0000 | 0000 | |

| 4 | 12 | 12/4 | 20 A @ 86° F | 0.58" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 0000 | 0000 | |

| 4 | 10 | 10/4 | 30 A @ 86° F | 0.7" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 0000 | 0000 | |

| 4 | 8 | 8/4 | 40 A @ 86° F | 0.84" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 00000 | 00000 | |

| 4 | 6 | 6/4 | 55 A @ 86° F | 1" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 00000 | 00000 | |

| 4 | 4 | 4/4 | 70 A @ 86° F | 1.19" | Black | Black, Green/Yellow | WTTC | __ | __ | 0000000 | 00000 | 00000 | |

- Use For: Motors, Interference Shielding

- Flexible

- Temperature Range: -40° to 220° F

- Inner Insulation: Polyethylene Plastic

Power Wire | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Ga. | Cable AWG | Current | OD | Outer Insulation Color | Inner Insulation Color | Industry Designation | Features | 5 ft. | 10 ft. | 20 ft. | 30 ft. | 50 ft. | 100 ft. | |

Double Shielded—1,000V AC/1,000V DC | |||||||||||||||

| 3 | 14 | 14/3 | 25 A @ 86° F | 0.5" | Black | Black, White | WTTC | Three Uninsulated Ground Wires | 0000000 | ||||||

| 3 | 12 | 12/3 | 30 A @ 86° F | 0.57" | Black | Black, White | WTTC | Three Uninsulated Ground Wires | 0000000 | ||||||

- Use For: Motors, Interference Shielding

- Flexible

- Temperature Range: -40° to 220° F

- Inner Insulation: Polyethylene Plastic

Power Wire | Signal Wire | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Ga. | Cable AWG | No. of | Ga. | Cable AWG | Current | OD | Outer Insulation Color | Inner Insulation Color | Industry Designation | Features | 5 ft. | 10 ft. | 20 ft. | 30 ft. | 50 ft. | |

Double Shielded—1,000V AC/1,000V DC | |||||||||||||||||

| 4 | 16 | 16/4 | 2 | 18 | 18/2 | 18 A @ 86° F | 0.57" | Black | Black, Green/Yellow | WTTC | Uninsulated Ground Wire | 00000000 | |||||

| 4 | 14 | 14/4 | 2 | 18 | 18/2 | 25 A @ 86° F | 0.62" | Black | Black, Green/Yellow | WTTC | Uninsulated Ground Wire | 0000000 | |||||

| 4 | 12 | 12/4 | 2 | 18 | 18/2 | 30 A @ 86° F | 0.65" | Black | Black, Green/Yellow | WTTC | Uninsulated Ground Wire | 0000000 | |||||

Abrasion-Resistant Wire

Run power over rough surfaces—this wire has thick insulation that stands up to wear and tear. It’s flame rated, which means it meets requirements for preventing the spread of fire. Also known as hook-up wire.

Wire with braided aramid fiber outer and silicone rubber inner insulation is best for your most rugged applications, such as wiring inside a motor. Its outer layer protects the wire if it’s cut or struck. Meanwhile, its inner layer makes it flexible enough to bend in tight spots. It’s also known as silicone rubber motor lead (SRML) wire.

For technical drawings and 3-D models, click on a part number.

- Use for motors, panel and equipment (hook-up)

- Flexible

- Temperature Range: -40° to 390° F

| Wire Ga. | Strand Count | Current | OD | Specifications Met | Outer Insulation Color | Length, ft. | Per Ft. | |

600V AC | ||||||||

|---|---|---|---|---|---|---|---|---|

| 14 | 7/22 | 55 A @ 86° F | 0.19" | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 00000 | |

| 12 | 19/24 | 70 A @ 86° F | 0.21" | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 0000 | |

| 10 | 19/23 | 92 A @ 86° F | 0.23" | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 0000 | |

Thin-Insulation Wire

- Use for buildings, motors, panel and equipment (hook-up)

- Flexible

- Temperature Range: -40° to 220° F

- Insulation: Modified Polyphenylene Ether (mPPE) Plastic

Nearly half the diameter and up to 40% lighter than standard wire of the same gauge and voltage, this wire fits in tight spaces. Also known as hook-up wire, it’s good for wiring electrical panels and plant floor equipment, or can be used as an alternative to building wire. It’s flame rated VW-1 to meet requirements for preventing the spread of flames, based on a timed test with vertically suspended material.

For technical drawings and 3-D models, click on a part number.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wire Ga. | Strand Count | Current | OD | Specifications Met | Choose an Outer Insulation Color | Length, ft. | 1-499 | 500-Up | |

Stranded Wire | |||||||||

600V AC | |||||||||

| 28 | 7/36 | 1 A @ 86° F | 0.03" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 00000 | 00000 | ||

| 26 | 7/34 | 1 A @ 86° F | 0.04" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 24 | 7/32 | 2 A @ 86° F | 0.04" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 22 | 7/30 | 3 A @ 86° F | 0.05" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 20 | 10/30 | 6 A @ 86° F | 0.06" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 18 | 16/30 | 8 A @ 86° F | 0.07" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 16 | 26/30 | 12 A @ 86° F | 0.08" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 000 | 000 | ||

| 14 | 41/30 | 24 A @ 86° F | 0.1" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 0000 | 000 | ||

| 12 | 65/30 | 30 A @ 86° F | 0.12" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 0000 | 0000 | ||

| 10 | 105/30 | 43 A @ 86° F | 0.14" | UL Listed, C-UL Listed, UL 2556 VW-1 | 0000000 | 0000 | 0000 | ||

Motor Winding Wire

- Use for motors

- Bend and Stay

- Maximum Temperature: 390° F

- Insulation: Polyamide

Also known as magnet wire, this wire is commonly used in motors, transformers, relays, and other high-speed winding applications. It meets NEMA 1000 MW-35C for material quality and -73C for use in sealed motors and material quality. It stays in the position you bend it.

For technical drawings and 3-D models, click on a part number.

| Wire Ga. | OD | Lg., ft. | Specifications Met | Each | |

Solid Wire | |||||

|---|---|---|---|---|---|

| 36 | 0.01" | 6,150 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 000000 |

| 36 | 0.01" | 12,300 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 34 | 0.01" | 3,900 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 34 | 0.01" | 7,800 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 32 | 0.01" | 4,350 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 32 | 0.01" | 8,700 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 30 | 0.01" | 3,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 30 | 0.01" | 6,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 28 | 0.02" | 2,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 28 | 0.02" | 4,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 26 | 0.02" | 1,500 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 26 | 0.02" | 3,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 24 | 0.02" | 790 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 24 | 0.02" | 2,000 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 22 | 0.03" | 750 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 22 | 0.03" | 1,500 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 000000 |

| 20 | 0.04" | 500 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 20 | 0.04" | 900 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 000000 |

| 18 | 0.04" | 300 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 18 | 0.04" | 600 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 16 | 0.06" | 125 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 16 | 0.06" | 250 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 14 | 0.07" | 80 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 14 | 0.07" | 160 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 12 | 0.09" | 50 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |

| 12 | 0.09" | 100 | NEMA 1000 MW-35C, NEMA 1000 MW-73C, UL Recognized Component | 0000000 | 00000 |