About Shaft Couplings

More

About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Plain Bearings

More

Oil-Embedded Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID, mm | Lg., mm | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 9 mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 12 | 10 | 270 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 12 | 14 | 390 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 14 | 10 | 270 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 14 | 14 | 390 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | 10° to 220° | 00000000 | 0000 |

| 14 | 16 | 440 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

Light Duty Dry-Running Sleeve Bearings

Use where high loads and speeds are not required.

Acetal bearings have low moisture absorption and are more chemical resistant than nylon and MDS-filled nylon bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Color | Temperature Range, °F | Each | |

Metric Acetal Bearings | ||||||

|---|---|---|---|---|---|---|

For 9mm Shaft Dia. | ||||||

| 12mm | 14mm | 47 lbs. @ 120 rpm | White | -20° to 180° | 0000000 | 00000 |

Ultra-Low-Friction Dry-Running Sleeve Bearings

Use these bearings in applications with frequent starts and stops because they operate with very little friction.

PTFE bearings have good chemical resistance.

Rulon J bearings handle higher operating temperatures than PTFE or thermoplastic-blend bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

Food Industry Dry-Running Sleeve Bearings

Made of FDA-listed materials or FDA compliant, these bearings are for use in food applications. They also withstand caustic and washdown environments.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Color | Temperature Range, °F | Specifications Met | Each | |

Metric UHMW Plastic Bearings | |||||||

|---|---|---|---|---|---|---|---|

For 9mm Shaft Dia. | |||||||

| 12mm | 14mm | 35 lbs. @ 120 rpm | White | -200° to 180° | FDA Compliant 21 CFR 177.1520 | 0000000 | 00000 |

Light Duty Dry-Running Flanged Sleeve Bearings

Use where high loads and speeds are not required.

Acetal bearings have low moisture absorption and are more chemical resistant than nylon and MDS-filled nylon bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Color | Temperature Range, °F | Each | |

Acetal Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 9mm Shaft Dia. | |||||||||

| 12mm | 14mm | 16mm | 2mm | 47 lbs. @ 120 rpm | 29 lbs. @ 120 rpm | White | -40° to 180° | 0000000 | 00000 |

Ultra-Low-Friction Dry-Running Flanged Sleeve Bearings

Use these bearings in applications with frequent starts and stops because they operate with very little friction.

Rulon J bearings stand up to higher temperatures than PTFE and thermoplastic-blend bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Color | Temperature Range, °F | Each | |

Rulon J Plastic Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 9 mm Shaft Dia. | |||||||||

| 13mm | 10mm | 17mm | 2mm | 90 lbs. @ 120 rpm | 85 lbs. @ 120 rpm | Gold | -400° to 500° | 00000000 | 000000 |

Multipurpose Dry-Running Flanged Sleeve Bearings

Reinforced with polyester fabric, these plastic bearings have load and speed capabilities comparable to metal bearings. Bearings resist corrosion in outdoor and saltwater environments.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Color | Temperature Range, °F | Each | |

Metric Polyester Fabric-Reinforced PTFE Plastic Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 9mm Shaft Dia. | |||||||||

| 14mm | 10mm | 19mm | 2.5mm | 310 lbs. @ 120 rpm | 360 lbs. @ 120 rpm | Blue | -40° to 150° | 0000000 | 000000 |

Multipurpose Flanged Sleeve Bearings

These bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Temperature Range, °F | PV Max. | Each | |

Metric 932 Bearing Bronze Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 9mm Shaft Dia. | ||||||||||

| 14mm | 6mm | 19mm | 2.5mm | 330 lbs. @ 120 rpm | 1,050 lbs. @ 120 rpm | Required | -350° to 450° | __ | 00000000 | 00000 |

| 14mm | 10mm | 19mm | 2.5mm | 550 lbs. @ 120 rpm | 1,050 lbs. @ 120 rpm | Required | -350° to 450° | 75,000 | 000000 | 0000 |

| 14mm | 14mm | 19mm | 2.5mm | 780 lbs. @ 120 rpm | 1,050 lbs. @ 120 rpm | Required | -350° to 450° | __ | 00000000 | 0000 |

Oil-Embedded Thrust Bearings

Startup friction causes these porous bronze bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Thick., mm | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 9 mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 18 | 1.5 | 650 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

Light Duty Dry-Running Thrust Bearings

Use where high loads and speeds are not required.

Thermoplastic bearings are fiber reinforced and lubricant infused for good wear resistance and low friction with light and medium loads.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD | Thick. | Dynamic Thrust Load Capacity | Color | Temp. Range, °F | Each | |

Thermoplastic Blend Bearings | ||||||

|---|---|---|---|---|---|---|

For 9 mm Shaft Dia. | ||||||

| 18mm | 1.15mm | 31 lbs. @ 120 rpm | Gray | -40° to 260° | 0000000 | 00000 |

Quick-Grip Screw-Clamp Bushings

Also known as Trantorque bushings, these tighten with a twist of the collar nut—no screws needed. As you tighten the collar nut, the inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Each | |

Steel | |||||

|---|---|---|---|---|---|

| 9mm | 20mm | 22mm | 450 | 0000000 | 000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars that are blue make it easy to identify metric collars at a glance. They’re tinted to match other blue metric fasteners.

303 stainless steel collars are corrosion resistant and highly machinable.

DIN 705 collars meet an international standard for shaft collar dimensions.

For technical drawings and 3-D models, click on a part number.

Set Screw | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Specifications Met | Each | |

Carbon Steel | |||||||

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 00000 |

Black-Oxide 1215 Carbon Steel | |||||||

| 9 | 16 | 8 | Hex Socket | 1 | __ | 00000000 | 0000 |

Blue Passivated Carbon Steel | |||||||

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 0000 |

303 Stainless Steel | |||||||

| 9 | 16 | 8 | Hex Socket | 1 | __ | 00000000 | 00000 |

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 0000 |

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel collars have moderate corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Washdown Clamping Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | White Acetal Plastic | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

| 9 | 24 | 9 | Socket Head Screw | 1 | 00000000 | 000000 |

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Washdown Clamping Two-Piece Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | White Acetal Plastic | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

| 9 | 24 | 9 | Socket Head Screw | 2 | 0000000 | 000000 |

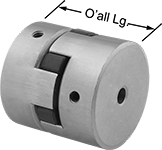

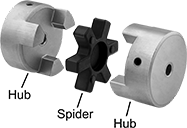

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance.

For technical drawings and 3-D models, click on a part number.

Servomotor Precision Flexible Shaft Couplings

Able to handle high twisting forces as well as misalignment, these couplings are good for high-performance servomotor applications. Couplings are aluminum and stainless steel for corrosion resistance and allow zero backlash (no play). They grip evenly around your shaft for a strong hold without marring the shaft. Tighten the clamping screws to secure.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

2017 Aluminum and 304 Stainless Steel | ||||||||||

| 3/16" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1/4" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 5/16" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 3/8" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 3/8" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1/2" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 5/8" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 5mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 6mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 8mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 9mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 9mm × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 10mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 14mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 15mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 16mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

Clamping Vibration-Damping Precision Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure. Good for precision motor and pump applications, the spider-shaped cushion reduces shock and compensates for minor shaft misalignment. Couplings allow zero backlash (no play).

A complete coupling consists of two hubs and one spider (each component sold separately). Hubs are lightweight, corrosion-resistant aluminum. Spiders are polyurethane for fair vibration damping and good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Durometer 98A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 150 | 0.003" | 0.8° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 00000 | 8,000 | 170 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 150 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 170 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

Durometer 92A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 58 | 0.005" | 0.9° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 000000 | 00000 | 8,000 | 70 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 | |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 58 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 70 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 |

Durometer 85A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 30 | 0.006" | 1° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 000000 | 00000 | 8,000 | 36 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 | |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 30 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 36 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 |