About Shaft Couplings

More

About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Plain Bearings

More

About Linear Bearings

More

Multipurpose Flanged Sleeve Bearings

These bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Temperature Range, °F | PV Max. | Each | |

Metric 932 Bearing Bronze Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 60mm Shaft Dia. | ||||||||||

| 70mm | 50mm | 80mm | 5mm | 18,600 lbs. @ 30 rpm | 10,300 lbs. @ 30 rpm | Required | -350° to 450° | 75,000 | 0000000 | 000000 |

| 70mm | 60mm | 80mm | 5mm | 22,300 lbs. @ 30 rpm | 10,300 lbs. @ 30 rpm | Required | -350° to 450° | __ | 00000000 | 00000 |

Oil-Embedded Thrust Bearings

Startup friction causes these porous bronze bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Thick., mm | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 60 mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 90 | 5 | 9,500 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

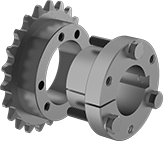

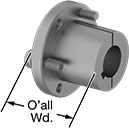

Quick-Disconnect (QD) Bushings

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect (QD) sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

Clamp On | ||||||||

SF Style Bushing | ||||||||

| 60mm | 52mm | 18mm | 4.4mm | 360 | Steel | Clamping Screws | 0000000 | 000000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

Bushings with a machine key fit into a matching keyway on a sprocket or pulley for high-torque applications.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Cast Iron | |||||||

Q1 Style Bushing with Machine Key | |||||||

| 60mm | 2 1/2" | 18mm | 4mm | 3° | 348 | 00000000 | 000000 |

Flush-Mount Screw-Clamp Bushings

Insert these bushings into the bore of your sprocket for flush or recessed mounting. They handle shock loads. When you tighten the included clamping screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 60mm | 90mm | 66mm | 54,700 | 363 | Steel | Clamping Screws | 0000000 | 0000000 |

Corrosion-Resistant Flush-Mount Screw-Clamp Bushings

Insert these nickel-plated steel bushings into the bore of your sprocket for flush or recessed mounting in wet environments. When you tighten the included clamping screws on these bushings, their inner sleeve contracts onto the shaft and their outer sleeve expands to hold your sprocket, pulley, or gear. This keeps bushings from slipping during sudden starts and stops.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia., mm | OD, mm | Overall Wd., mm | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 60 | 90 | 32 | 24,800 | 360 | Nickel-Plated Steel | Clamping Screws | 0000000 | 0000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars that are blue make it easy to identify metric collars at a glance. They’re tinted to match other blue metric fasteners.

303 stainless steel collars are corrosion resistant and highly machinable.

DIN 705 collars meet an international standard for shaft collar dimensions.

For technical drawings and 3-D models, click on a part number.

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel and chrome-plated steel collars have moderate corrosion resistance with a bright finish. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Keyway | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Wd., mm | Dp., mm | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||||

| 60 | 88 | 19 | 18 | 4.4 | Socket Head Screw | 2 | 0000000 | 0000000 |

Clamping Two-Piece Shaft Collars with Wrench Flats

Use a wrench to rotate your drive shaft without marring or gouging the shaft. Fasten one of these collars onto your shaft, position a wrench on the collar’s wrench flats, and then rotate the entire shaft/collar assembly to adjust the shaft. The two-piece design allows you to install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Set Screw Two-Piece Shaft Collars

Tighten the set screw to bite into an unhardened shaft for a secure hold. The two-piece design allows you to install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Clamping screws provide extra grip.

Carbon steel collars are strong and wear resistant. Their black-oxide finish is somewhat corrosion resistant, but only in dry environments. Their dark color can be useful for matching other parts in your system.

303 stainless steel collars are corrosion resistant and highly machinable.

For technical drawings and 3-D models, click on a part number.

Weldable Two-Piece Shaft Collars

Install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Because they’re grade 1018 carbon steel, you can easily weld them to other components. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | 1018 Carbon Steel | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

For Round Shafts | ||||||

| 60 | 88 | 19 | Socket Head Screw | 2 | 00000000 | 000000 |

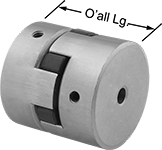

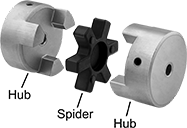

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance.

For technical drawings and 3-D models, click on a part number.

High-Temperature Linear Ball Bearings

The choice for low-friction motion in high-temperature environments. Bearings are for use with round end-supported shafts and have a fixed-alignment design for applications where shaft misalignment is unlikely. To install, slide bearings into a housing (not included). For bearings with retaining ring grooves, secure with two retaining rings (sold individually).

For technical drawings and 3-D models, click on a part number.

Bearings | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Load Capacity, lbs. | External Retaining Rings | ||||||||||||

| For Shaft Diameter, mm | Overall Lg., mm | For Housing ID, mm | Retaining Ring Groove End-to-End Length, mm | With End Seals | Dynamic | Static | Dynamic Load Capacity at Maximum Temperature | Temperature Range, ° F | For Shaft Material | Each | Each | ||

Steel Bearings with Steel Balls | |||||||||||||

| 60 | 110 | 90.000 - 90.035 | 85 | No | 1,050 | 2,200 | 1050 lbs. @ 230° F | -4° to 230° | Stainless Steel, Steel | 00000000 | 0000000 | 000000000 | 00000 |

Flange-Mounted Linear Ball Bearings

The flanged housing makes these bearings a good solution for vertical linear motion applications. All are for use with round end-supported shafts and have a fixed-alignment design for use where shaft misalignment is unlikely. End seals keep lubricant in and dirt out.

For technical drawings and 3-D models, click on a part number.

Overall, mm | Flange, mm | Load Capacity, lbs. | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Lg. | Wd. | Ht. | Thick. | OD | Bolt Circle Dia., mm | OD, mm | Dynamic | Static | Temperature Range, ° F | For Shaft Material | No. of | Dia., mm | Each | |

Steel Bearings with Round Flanged Housing | |||||||||||||||

| 60 | 209 | 134 | 134 | 18 | 134 | 112 | 90 | 1,650 | 4,450 | -4° to 176° | Stainless Steel, Steel | 4 | 11 | 00000000 | 0000000 |

Steel Bearings with Square Flanged Housing | |||||||||||||||

| 60 | 125 | 106 | 106 | 18 | __ | 112 | 90 | 1,050 | 2,200 | -4° to 176° | Stainless Steel, Steel | 4 | 11 | 00000000 | 000000 |