About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Plain Bearings

More

About Shaft Couplings

More

Oil-Embedded Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID, mm | Lg., mm | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 32 mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 38 | 20 | 1,950 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

| 38 | 25 | 2,450 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 40 | 20 | 1,950 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 40 | 25 | 2,450 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 40 | 30 | 2,950 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 40 | 32 | 3,150 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 40 | 40 | 3,950 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

High-Load Oil-Embedded Sleeve Bearings

Increased iron content makes these bearings stronger and more resistant to shock loads than standard oil-embedded bearings; however they operate at lower speeds. Startup friction causes them to release a thin layer of oil on the bearing’s surface. Color is silver because of the iron. These bearings are also magnetic due to the high iron content.

863 iron-copper bearings are also known as Super Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 32mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 40mm | 32mm | 5,600 lbs. @ 30 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 000000 |

Ultra-Low-Friction Oil-Embedded Sleeve Bearings

For applications with frequent starts and stops, the oil in these bearings contains particles of slippery PTFE that lubricate the bearing during startup.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID, mm | Lg., mm | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 32mm Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 40 | 32 | 3,150 lbs. @ 30 rpm | Lubricated | SAE 20 Oil with PTFE | -60° to 300° | 00000000 | 000000 |

Light Duty Dry-Running Sleeve Bearings

Use where high loads and speeds are not required.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

Food Industry Dry-Running Sleeve Bearings

Made of FDA-listed materials or FDA compliant, these bearings are for use in food applications. They also withstand caustic and washdown environments.

Acetal bearings are FDA compliant for direct contact with food. They’re also bright blue, making them easy to spot if they fall into your line.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Color | Temperature Range, °F | Specifications Met | Each | |

Metric Acetal Plastic Bearings | |||||||

|---|---|---|---|---|---|---|---|

For 32mm Shaft Dia. | |||||||

| 36mm | 40mm | 1,750 lbs. @ 30 rpm | Blue | -50° to 190° | FDA Compliant 21 CFR 177.1550 | 00000000 | 00000 |

Oil-Embedded Flanged Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They’re flanged, so they handle loads both parallel and perpendicular to the shaft. They’re also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

Metric 841 Bronze Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 32mm Shaft Dia. | ||||||||||

| 38mm | 32mm | 46mm | 4mm | 3,150 lbs. @ 30 rpm | 2,650 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

High-Load Oil-Embedded Flanged Sleeve Bearings

Increased iron content makes these bearings stronger and more resistant to shock loads than standard oil-embedded bearings; however they operate at lower speeds. Startup friction causes these bearings to release a thin layer of oil onto their surface. Color is silver because of the iron.

863 iron-copper bearings are also known as Super Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

863 Iron-Copper Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 32mm Shaft Dia. | ||||||||||

| 38mm | 32mm | 46mm | 4mm | 5,600 lbs. @ 30 rpm | 3,250 lbs. @ 30 rpm | Lubricated | ISO 460 Oil | -15° to 300° | 00000000 | 000000 |

High-Load Ultra-Low-Friction Oil-Embedded Flanged Sleeve Bearings

With oil for reduced friction and iron for added strength, these bearings handle frequent stops and starts in high-load applications. They withstand greater weight and shock loads than standard bearings, but operate at lower speeds.

For technical drawings and 3-D models, click on a part number.

| For Housing ID, mm | Length, mm | Flange OD, mm | Flange Thickness, mm | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

863 Iron-Copper Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

32 mm Shaft Dia. | ||||||||||

| 38 | 32 | 46 | 4 | 5,600 lbs. @ 30 rpm | 3,250 lbs. @ 30 rpm | Lubricated | ISO 460 Oil | -60° to 300° | 00000000 | 000000 |

Multipurpose Flanged Sleeve Bearings

These bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Temperature Range, °F | PV Max. | Each | |

Metric 932 Bearing Bronze Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 32mm Shaft Dia. | ||||||||||

| 38mm | 20mm | 46mm | 4mm | 3,950 lbs. @ 30 rpm | 5,300 lbs. @ 30 rpm | Required | -350° to 450° | __ | 00000000 | 000000 |

| 38mm | 32mm | 46mm | 4mm | 6,300 lbs. @ 30 rpm | 5,300 lbs. @ 30 rpm | Required | -350° to 450° | 75,000 | 00000000 | 00000 |

Light Duty Dry-Running Thrust Bearings

Use where high loads and speeds are not required.

Thermoplastic bearings are fiber reinforced and lubricant infused for good wear resistance and low friction with light and medium loads.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD | Thick. | Dynamic Thrust Load Capacity | Color | Temp. Range, °F | Each | |

Thermoplastic Blend Bearings | ||||||

|---|---|---|---|---|---|---|

For 32 mm Shaft Dia. | ||||||

| 54mm | 1.5mm | 245 lbs. @ 30 rpm | Gray | -40° to 260° | 0000000 | 00000 |

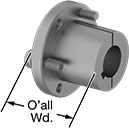

Quick-Disconnect (QD) Bushings

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect (QD) sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

Clamp On | ||||||||

SD Style Bushing | ||||||||

| 32mm | 46mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 000000 |

SDS Style Bushing | ||||||||

| 32mm | 35mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 00000 |

SH Style Bushing | ||||||||

| 32mm | 33mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 00000 |

SK Style Bushing | ||||||||

| 32mm | 49mm | 10mm | 3.3mm | 180 | Steel | Clamping Screws | 0000000 | 00000 |

Taper-Lock Bushings

Mount these hubless bushings flush into your sprocket or pulley for a slim profile with no protruding screws. They are for use with taper-lock sprockets of the same bushing style. As you tighten the included set screws, the bushing grips the shaft and pulls it into your sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

1210 Style Bushing | |||||||||

| 32mm | 25mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 000000 |

1610 Style Bushing | |||||||||

| 32mm | 25mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1615 Style Bushing | |||||||||

| 32mm | 38mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

2012 Style Bushing | |||||||||

| 32mm | 32mm | 10mm | 3.3mm | 8° | 280 | Steel | Set Screws | 000000000 | 00000 |

2517 Style Bushing | |||||||||

| 32mm | 44mm | 10mm | 3.3mm | 8° | 430 | Steel | Set Screws | 000000000 | 00000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

Bushings with a machine key fit into a matching keyway on a sprocket or pulley for high-torque applications.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||||

H Style Bushing with Machine Key | |||||||

| 32mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 000000 |

Flush-Mount Screw-Clamp Bushings

Insert these bushings into the bore of your sprocket for flush or recessed mounting. They handle shock loads. When you tighten the included clamping screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 32mm | 60mm | 54mm | 10,350 | 142 | Steel | Clamping Screws | 0000000 | 0000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars that are blue make it easy to identify metric collars at a glance. They’re tinted to match other blue metric fasteners.

303 stainless steel collars are corrosion resistant and highly machinable.

DIN 705 collars meet an international standard for shaft collar dimensions.

For technical drawings and 3-D models, click on a part number.

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 32 | 54 | 15 | Socket Head Screw | 1 | 000000000 | 000000 |

Quick-Release Clamping Shaft Collars

Installing and removing a collar is as easy as pushing down and lifting up a clamp lever. Collars clamp evenly around the shaft to create a strong, mar-free hold. All have a clamping screw to adjust lever tension. Made of anodized aluminum, they are lightweight with good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | Black Anodized 6061 Aluminum | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

| 32mm | 75mm | 15mm | Socket Head Screw | 1 | 00000000 | 000000 |

Tight-Hold Quick-Release Clamping Shaft Collars

A threaded lever lets you tighten these collars with more torque than other quick-release styles, ensuring that they stay put on your shaft. Use them to quickly move components or make setup changes, such as on packing equipment, printers, or label feeding machines. To make adjustments in tight spaces, lift the lever and twist to the side. Similar to a ratchet, you can lift the lever to disengage from the threads and reposition.

Black oxide steel collars are very strong, but will rust if exposed to moisture.

Anodized aluminum is strong and lightweight. It can withstand humidity without rusting, but water left on the surface will cause it to corrode.

303 stainless steel collars can handle frequent exposure to water without rusting.

For technical drawings and 3-D models, click on a part number.

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel and chrome-plated steel collars have moderate corrosion resistance with a bright finish. Aluminum collars are lightweight and have good corrosion resistance. In addition to the benefits of aluminum, anodized aluminum collars have extra corrosion resistance, and you can tighten the clamping screw with more torque, so they stay in place. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 32 | 54 | 15 | Socket Head Screw | 2 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 32 | 54 | 15 | Socket Head Screw | 2 | 0000000 | 00000 |

2024 Aluminum | ||||||

| 32 | 54 | 15 | Socket Head Screw | 2 | 0000000 | 00000 |

| 32 | 60 | 12 | Socket Head Screw | 2 | 0000000 | 00000 |

Anodized 2024 Aluminum | ||||||

| 32 | 54 | 15 | Socket Head Screw | 2 | 0000000 | 00000 |

303 Stainless Steel | ||||||

| 32 | 54 | 15 | Socket Head Screw | 2 | 0000000 | 00000 |

| 32 | 60 | 12 | Socket Head Screw | 2 | 0000000 | 00000 |

Quick-Release Two-Piece Clamping Shaft Collars

Make quick adjustments to these shaft collars with a lever on the side. Often used on packing equipment, printers, and label feeding machines, these collars are used to quickly move components or make setup changes. To make adjustments in tight spaces, lift the lever and twist to either side. Similar to a ratchet, you can tighten and loosen with the lever down; lift the lever to disengage from the threads and reposition. The two pieces of the collar separate, so you can install them anywhere on a shaft without removing components or having access to the end.

Black oxide steel collars are very strong, but will rust if exposed to moisture.

Anodized aluminum is strong and lightweight. It can withstand humidity without rusting, but water left on the surface will cause it to corrode.

303 stainless steel collars can handle frequent exposure to water without rusting.

For technical drawings and 3-D models, click on a part number.

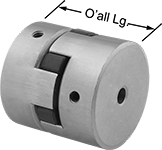

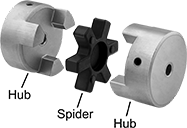

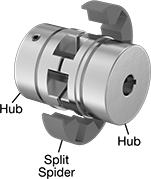

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

A complete coupling consists of two hubs and one spider, or two hubs, one split spider, and one retaining ring (all components sold separately). Split spiders are easier to install and replace than standard spiders because there’s no need for tools or removing your hubs. Twist-lock them in place using a retaining ring.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance. Polyurethane spiders and split spiders provide fair vibration damping and good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Buna-N Rubber Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | ||||||||||||

| Overall Lg., mm | OD, mm | For Shaft Type | For Motion Type | For Shaft Dia., mm | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 89 | 65 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 7,000 | 315 | 0.015" | 1° | -40° to 212° | 0000000 | 000000 |

| 124 | 115 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 5,000 | 1,725 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 |

| 137 | 127 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 4,200 | 2,340 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 |

Hytrel Rubber Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | ||||||||||||

| Overall Lg., mm | OD, mm | For Shaft Type | For Motion Type | For Shaft Dia., mm | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 89 | 65 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 3,600 | 790 | 0.015" | 0.5° | -55° to 245° | 0000000 | 0000000 |

| 124 | 115 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 5,000 | 4,680 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 |

| 137 | 127 | Keyed | Forward/Reverse, Start/Stop | 32 | 0000000 | 000000 | 4,200 | 6,225 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 |

Polyurethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | 347 Stainless Steel Retaining Rings | |||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | Each | |||

| 4 7/32" | 3 21/64" | Keyed | Forward/Reverse, Start/Stop | 32mm | 0000000 | 000000 | 5,900 | 2,180 | 0.03" | 2° | -30° to 200° | 0000000 | 0000000 | 0000000 | 0000000 |

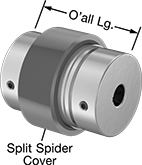

High-Torque Set Screw Flexible Shaft Couplings

The thick split spider on these couplings takes on twice as much torque as standard split spiders, while a set screw holds the hubs in place on your shaft. Also known as jaw couplings, use them to connect motors to pumps, mixers, and other high-torque equipment. You don’t need to lubricate them.

For a complete coupling, you’ll need two hubs, one split spider, and a split spider cover (all sold separately).

Hubs attach to the end of your shaft.

Split spiders cushion between the two hubs to dampen vibration, reduce shocks, and handle shaft misalignment, extending the life of bearings, seals, and motors. You can replace them without having to remove the hubs or move your shaft and equipment around, which reduces the risk of needing to realign the shaft. Spiders with medium-soft hardness are the most commonly used and are good for applications that start, stop, and reverse often. Those with medium hardness handle higher torque than those with medium-soft hardness, but they don’t reduce vibration as well.

Split spider covers hold the spider in place.

For technical drawings and 3-D models, click on a part number.

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 4 29/32" | 3 3/16" | Forward/Reverse, Start/Stop | 32mm | 000000 | 0000000 | 7,000 | 3,425 | 0.039" | 2° | -60° to 212° | Red | 0000000 | 000000 | 0000000 | 000000 |

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 4 29/32" | 3 3/16" | Forward/Reverse, Start/Stop | 32mm | 000000 | 0000000 | 7,000 | 6,460 | 0.039" | 2° | -60° to 212° | Blue | 0000000 | 000000 | 0000000 | 000000 |

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 4 29/32" | 3 3/16" | Forward/Reverse, Start/Stop | 32mm | 000000 | 0000000 | 7,000 | 6,460 | 0.039" | 2° | -60° to 350° | White | 0000000 | 0000000 | 0000000 | 000000 |

Servomotor Precision Flexible Shaft Couplings

Able to handle high twisting forces as well as misalignment, these couplings are good for high-performance servomotor applications. Couplings are aluminum and stainless steel for corrosion resistance and allow zero backlash (no play). They grip evenly around your shaft for a strong hold without marring the shaft. Tighten the clamping screws to secure.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

2017 Aluminum and 304 Stainless Steel | ||||||||||

| 3/4" × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 0000000 |

| 7/8" × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1" × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 20mm × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 24mm × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 28mm × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 32mm × 32mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 32mm × 35mm | 2 57/64" | 2 11/16" | 10,000 | 530 | 0.013" | 1° | 0.035" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

High-Speed Servomotor Precision Flexible Shaft Couplings

Connect shafts and ball screws to high-speed servomotors and stepper motors—these shaft couplings handle four times more speed than standard servomotor couplings. They’re often found on high-torque motors that frequently start and stop, such as those used with packaging machines, press brakes, and semiconductor manufacturing equipment.

With aluminum hubs joined by a flexible fluoroelastomer or nitrile rubber core, these shaft couplings dampen vibration and adjust for misalignment. When machines accelerate and decelerate quickly, these couplings remain stiff to maintain accuracy and repeatability, which prevents equipment from moving out of place. They also resist backlash, meaning all of the turning force from the motor is passed on to the connected shaft. The core resists water, petroleum-based chemicals, and inorganic acids while also insulating bearings, encoders, and other shaft components from stray electric current. Clamping screws provide hold without marring shafts; they’re useful in applications where shafts are frequently assembled and disassembled.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

2017 Aluminum with Nitrile Rubber Center | ||||||||||

| 25mm × 32mm | 2 61/64" | 2 43/64" | 9,000 | 575 | 0.008" | 1.5° | 0.012" | Forward/Reverse, Start/Stop | 00000000 | 0000000 |

Clamping Vibration-Damping Precision Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure. Good for precision motor and pump applications, the spider-shaped cushion reduces shock and compensates for minor shaft misalignment. Couplings allow zero backlash (no play).

A complete coupling consists of two hubs and one spider (each component sold separately). Hubs are lightweight, corrosion-resistant aluminum. Spiders are polyurethane for fair vibration damping and good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Durometer 98A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 80mm | 57.2mm | Round | Forward/Reverse, Start/Stop | 32mm | 0000000 | 0000000 | 8,000 | 820 | 0.004" | 0.8° | 0° to 180° | 0000000 | 000000 |

Durometer 92A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 80mm | 57.2mm | Round | Forward/Reverse, Start/Stop | 32mm | 0000000 | 0000000 | 8,000 | 570 | 0.005" | 0.9° | 0° to 180° | 0000000 | 000000 |