About Shaft Couplings

More

About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Plain Bearings

More

Oil-Embedded Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 1 7/16" Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 1 5/8" | 1" | 2,850 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | 10° to 220° | 00000000 | 00000 |

| 1 5/8" | 1 1/2" | 4,300 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | 10° to 220° | 00000000 | 0000 |

| 1 5/8" | 2" | 5,750 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 1 3/4" | 1" | 2,850 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 1 3/4" | 1 1/4" | 3,550 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | 10° to 220° | 00000000 | 0000 |

| 1 3/4" | 1 1/2" | 4,300 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 1 3/4" | 1 3/4" | 5,000 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 1 3/4" | 2" | 5,750 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

High-Temperature Dry-Running Sleeve Bearings

Graphite provides a layer of dry lubrication that operates in high-temperature environments.

Graphalloy bearings perform at extreme temperatures and under water. They are electrically conductive and wear resistant.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication Method | Temperature Range, °F | Each | |

Graphalloy | ||||||

|---|---|---|---|---|---|---|

For 1 7/16" Shaft Dia. | ||||||

| 1 15/16" | 2 1/4" | 2,400 lbs. @ 30 rpm | Embedded | -450° to 750° | 0000000 | 0000000 |

Oil-Embedded Thrust Bearings

Startup friction causes these porous bronze bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD | Thick. | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 1 7/16" Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 2 1/2" | 1/8" | 6,550 lbs. @ 30 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

Mounted Sleeve Bearings

A reliable classic—these babbitt bearings are strong and corrosion resistant.

Bearings with split housing have a removable section for easy maintenance.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Center Ht. | Ht. | Lg. | Wd. | Bearing Wd. | Hole Lg. | Hole Wd. | Hole Ctr.-to-Ctr. | Dynamic Radial Load Cap. | Temp. Range, °F | Alignment Style | Lubrication | Each | |

Babbitt Bearings with Split Cast Iron Housing | ||||||||||||||

| 1 7/16" | 1 3/8" | 2 11/16" | 6 1/4" | 3" | 3" | 11/16" | 1/2" | 4 7/8" | 625 lbs. @ 30 rpm | 0° to 130° | Fixed Alignment | Required | 0000000 | 0000000 |

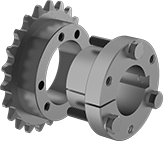

Quick-Disconnect (QD) Bushings

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect (QD) sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

Clamp On | ||||||||

SD Style Bushing | ||||||||

| 1 7/16" | 1 13/16" | 3/8" | 3/16" | 108 | Steel | Clamping Screws | 00000000 | 000000 |

SDS Style Bushing | ||||||||

| 1 7/16" | 1 3/8" | 3/8" | 3/16" | 108 | Steel | Clamping Screws | 00000000 | 00000 |

SF Style Bushing | ||||||||

| 1 7/16" | 2 1/16" | 3/8" | 3/16" | 360 | Steel | Clamping Screws | 00000000 | 00000 |

SH Style Bushing | ||||||||

| 1 7/16" | 1 5/16" | 3/8" | 1/16" | 108 | Steel | Clamping Screws, Machine Key | 00000000 | 00000 |

SK Style Bushing | ||||||||

| 1 7/16" | 1 15/16" | 3/8" | 3/16" | 180 | Steel | Clamping Screws | 00000000 | 00000 |

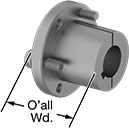

Taper-Lock Bushings

Mount these hubless bushings flush into your sprocket or pulley for a slim profile with no protruding screws. They are for use with taper-lock sprockets of the same bushing style. As you tighten the included set screws, the bushing grips the shaft and pulls it into your sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

1310 Style Bushing | |||||||||

| 1 7/16" | 1" | 3/8" | 1/8" | 8° | 175 | Steel | Machine Key, Set Screws | 000000000 | 000000 |

1610 Style Bushing | |||||||||

| 1 7/16" | 1" | 3/8" | 3/16" | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1615 Style Bushing | |||||||||

| 1 7/16" | 1 1/2" | 3/8" | 3/16" | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

2012 Style Bushing | |||||||||

| 1 7/16" | 1 1/4" | 3/8" | 3/16" | 8° | 280 | Steel | Set Screws | 000000000 | 00000 |

2517 Style Bushing | |||||||||

| 1 7/16" | 1 3/4" | 3/8" | 3/16" | 8° | 430 | Steel | Set Screws | 000000000 | 00000 |

3020 Style Bushing | |||||||||

| 1 7/16" | 2" | 3/8" | 3/16" | 8° | 800 | Steel | Set Screws | 000000000 | 00000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||||

H Style Bushing | |||||||

| 1 7/16" | 1 1/4" | 3/8" | 7/64" | 3° | 95 | 00000000 | 000000 |

Flanged Screw-Clamp Bushings

A mounting flange prevents movement during tightening. These bushings are good for shock loads. When you tighten the included screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 1 7/16" | 2 5/16" | 1 1/2" | 6,250 | 150 | Steel | Clamping Screws | 0000000 | 0000000 |

Flush-Mount Screw-Clamp Bushings

Insert these bushings into the bore of your sprocket for flush or recessed mounting. They handle shock loads. When you tighten the included clamping screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 1 7/16" | 2 9/16" | 1 1/32" | 7,600 | 150 | Steel | Clamping Screws | 0000000 | 000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars with a zinc-plated finish have an outer layer of zinc that protects the steel from rust and extends the life of the collar. 303 stainless steel collars are corrosion resistant and highly machinable.

316 stainless steel collars are the most corrosion resistant while still being nearly as strong as steel collars. You can expose them to salt water, chlorine solutions, and chemicals without rusting.

Aluminum collars are lightweight and have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Set Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 3/4" | Hex Socket | 1 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 3/4" | Hex Socket | 1 | 0000000 | 00000 |

303 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 3/4" | Hex Socket | 1 | 0000000 | 00000 |

316 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 3/4" | Hex Socket | 1 | 0000000 | 000000 |

6061 Aluminum | ||||||

| 1 7/16" | 2 1/4" | 3/4" | Hex Socket | 1 | 0000000 | 00000 |

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel collars have moderate corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance. 316 stainless steel collars have excellent corrosion and chemical resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 1 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 1 | 0000000 | 00000 |

2024 Aluminum | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 1 | 0000000 | 00000 |

303 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 1 | 0000000 | 00000 |

316 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 1 | 0000000 | 00000 |

Extra-Grip Clamping Shaft Collars

With larger clamping screws than those found on standard clamping collars, these provide a stronger grip on your shaft without using additional screws. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure. Collars are black-oxide steel, which offers some corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | Black-Oxide 1215 Carbon Steel | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

| 1 7/16" | 2 3/4" | 5/8" | Socket Head Screw | 1 | 0000000 | 000000 |

Tight-Hold Quick-Release Clamping Shaft Collars

A threaded lever lets you tighten these collars with more torque than other quick-release styles, ensuring that they stay put on your shaft. Use them to quickly move components or make setup changes, such as on packing equipment, printers, or label feeding machines. To make adjustments in tight spaces, lift the lever and twist to the side. Similar to a ratchet, you can lift the lever to disengage from the threads and reposition.

Black oxide steel collars are very strong, but will rust if exposed to moisture.

Anodized aluminum is strong and lightweight. It can withstand humidity without rusting, but water left on the surface will cause it to corrode.

303 stainless steel collars can handle frequent exposure to water without rusting.

For technical drawings and 3-D models, click on a part number.

Lever | Clamping Screw | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Lg. | Ht. | Material | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | |||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1.781" | 1.594" | Zinc | Socket Head Screw | 1 | 0000000 | 000000 |

Anodized 2024 Aluminum | |||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1.781" | 1.594" | Zinc | Socket Head Screw | 1 | 0000000 | 00000 |

303 Stainless Steel | |||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1.781" | 1.594" | Zinc | Socket Head Screw | 1 | 0000000 | 000000 |

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel and chrome-plated steel collars have moderate corrosion resistance with a bright finish. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance. 316 stainless steel collars have excellent corrosion and chemical resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 0000000 | 00000 |

Chrome-Plated 1215 Carbon Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 0000000 | 00000 |

2024 Aluminum | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 00000000 | 00000 |

303 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 0000000 | 00000 |

316 Stainless Steel | ||||||

| 1 7/16" | 2 1/4" | 9/16" | Socket Head Screw | 2 | 0000000 | 00000 |

Washdown Clamping Two-Piece Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

For technical drawings and 3-D models, click on a part number.

Extra-Grip Clamping Two-Piece Shaft Collars

With larger screws than those found on standard clamping collars, these provide a stronger grip on your shaft without using additional screws. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars offer some corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | Number Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 1 7/16" | 2 3/4" | 5/8" | Socket Head Screw | 2 | 0000000 | 000000 |

Quick-Release Two-Piece Clamping Shaft Collars

Make quick adjustments to these shaft collars with a lever on the side. Often used on packing equipment, printers, and label feeding machines, these collars are used to quickly move components or make setup changes. To make adjustments in tight spaces, lift the lever and twist to either side. Similar to a ratchet, you can tighten and loosen with the lever down; lift the lever to disengage from the threads and reposition. The two pieces of the collar separate, so you can install them anywhere on a shaft without removing components or having access to the end.

Black oxide steel collars are very strong, but will rust if exposed to moisture.

Anodized aluminum is strong and lightweight. It can withstand humidity without rusting, but water left on the surface will cause it to corrode.

303 stainless steel collars can handle frequent exposure to water without rusting.

For technical drawings and 3-D models, click on a part number.

Lever | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Ht. | Lg. | Type | No. Included | Each | |

Black Oxide 1215 Carbon Steel | ||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1 19/32" | 1 25/32" | Socket Head Screw | 2 | 00000000 | 000000 |

Anodized 2024 Aluminum | ||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1 19/32" | 1 25/32" | Socket Head Screw | 2 | 00000000 | 00000 |

303 Stainless Steel | ||||||||

| 1 7/16" | 2 3/8" | 19/32" | 1 19/32" | 1 25/32" | Socket Head Screw | 2 | 00000000 | 000000 |

Set Screw Two-Piece Shaft Collars

Tighten the set screw to bite into an unhardened shaft for a secure hold. The two-piece design allows you to install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Clamping screws provide extra grip.

Carbon steel collars are strong and wear resistant. Their black-oxide finish is somewhat corrosion resistant, but only in dry environments. Their dark color can be useful for matching other parts in your system.

For technical drawings and 3-D models, click on a part number.

Set Screw | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||||

| 1 7/16" | 2 1/4" | 9/16" | Hex Socket | 1 | Socket Head Screw | 2 | 0000000 | 000000 |

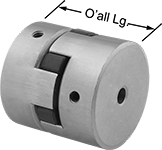

Clamping Shaft Couplings

Designed to grip evenly around your shaft, clamping couplings provide more holding power than set screw couplings without marring the shaft. Slide onto the end of your shaft and tighten the clamping screws to secure. Good for high-torque applications, rigid couplings connect two shafts that are aligned, allowing for no relative movement between the shafts.

Stainless steel couplings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | For Motion Type | Each | |

Steel | |||||||

|---|---|---|---|---|---|---|---|

For Keyed Shafts | |||||||

| 1 7/16" × 1 7/16" | 3 7/8" | 2 5/8" | 4,000 | 6,800 | Forward/Reverse, Start/Stop, Continuous | 00000000 | 0000000 |

For Round Shafts | |||||||

| 1 7/16" × 1" | 3 7/8" | 2 5/8" | 4,000 | 6,800 | Forward/Reverse, Start/Stop, Continuous | 00000000 | 000000 |

| 1 7/16" × 1 7/16" | 3 7/8" | 2 5/8" | 4,000 | 6,800 | Forward/Reverse, Start/Stop, Continuous | 00000000 | 000000 |

303 Stainless Steel | |||||||

For Keyed Shafts | |||||||

| 1 7/16" × 1 7/16" | 3 7/8" | 2 5/8" | 4,000 | 4,000 | Forward/Reverse, Start/Stop, Continuous | 0000000 | 000000 |

For Round Shafts | |||||||

| 1 7/16" × 1" | 3 7/8" | 2 5/8" | 4,000 | 4,000 | Forward/Reverse, Start/Stop, Continuous | 00000000 | 000000 |

| 1 7/16" × 1 7/16" | 3 7/8" | 2 5/8" | 4,000 | 4,000 | Forward/Reverse, Start/Stop, Continuous | 00000000 | 000000 |

Two-Piece Shaft Coupling Bridges

When your shafts are not close enough to use standard couplings, these have the length to bridge the gap. Install them anywhere on a shaft without removing components or having access to the ends of the shaft. Tighten the clamping screws to secure. Good for high-torque applications, rigid couplings connect two shafts that are aligned, allowing for no relative movement between the shafts.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | For Motion Type | Each | |

Cast Iron | |||||||

|---|---|---|---|---|---|---|---|

For Keyed Shafts | |||||||

| 1 7/16" | 7 1/8" | 4 1/2" | 4,130 | 3,500 | Forward/Reverse, Start/Stop, Continuous | 0000000 | 0000000 |

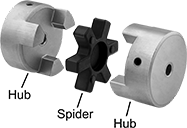

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

A complete coupling consists of two hubs and one spider, or two hubs, one split spider, and one retaining ring (all components sold separately). Split spiders are easier to install and replace than standard spiders because there’s no need for tools or removing your hubs. Twist-lock them in place using a retaining ring.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance. Polyurethane spiders and split spiders provide fair vibration damping and good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Buna-N Rubber Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 4 7/32" | 3 21/64" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 5,000 | 790 | 0.015" | 1° | -40° to 212° | 0000000 | 000000 |

| 4 1/2" | 3 3/4" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 5,000 | 1,240 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 |

| 4 7/8" | 4 1/2" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 5,000 | 1,725 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 |

| 5 11/32" | 5" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 4,200 | 2,340 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 |

Hytrel Rubber Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 4 7/32" | 3 21/64" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 3,600 | 2,265 | 0.015" | 0.5° | -55° to 245° | 0000000 | 0000000 |

| 4 1/2" | 3 3/4" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 3,600 | 3,705 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 |

| 4 7/8" | 4 1/2" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 5,000 | 4,680 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 |

| 5 11/32" | 5" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 4,200 | 6,225 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 |

Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 4 7/32" | 3 21/64" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 3,600 | 1,185 | 0.015" | 1° | -30° to 160° | 0000000 | 0000000 |

| 4 1/2" | 3 3/4" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 3,600 | 1,860 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 |

Polyurethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | 347 Stainless Steel Retaining Rings | |||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | Each | |||

| 4 7/32" | 3 21/64" | Keyed | Forward/Reverse, Start/Stop | 1 7/16" | 0000000 | 000000 | 5,900 | 2,180 | 0.03" | 2° | -30° to 200° | 0000000 | 0000000 | 0000000 | 0000000 |