How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

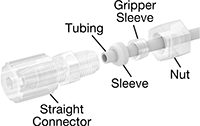

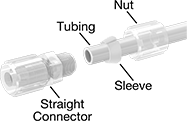

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PFA fittings stand up to harsh substances. They’re made through a melting process. PTFE fittings are highly resistant to most acids, alcohols, detergents, and solvents. They’re made by machining. Their nut is made of PVDF, which is resistant to halogens such as chlorine and bromine, strong acids such as hydrofluoric and nitric acids, and organic solvents.

For technical drawings and 3-D models, click on a part number.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD | Pipe Size | Material | Color | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 1/4 | PFA Plastic | White | 120 psi @ 72° F | 1/2" | 1/4" | 000000000 | 0000000 |

| 3/8" | 3/8 | PFA Plastic | White | 120 psi @ 72° F | 5/8" | 1/4" | 000000000 | 000000 |

| 1/2" | 1/2 | PFA Plastic | White | 120 psi @ 72° F | 3/4" | 1/4" | 000000000 | 000000 |

| 3/4" | 3/4 | PFA Plastic | White | 120 psi @ 72° F | 1" | 1/2" | 000000000 | 000000 |

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD | Material | Color | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

| 1/8" | PFA Plastic | White | 125 psi @ 72° F | 5/16" | 1/4" | 000000000 | 0000000 |

| 1/4" | PFA Plastic | White | 125 psi @ 72° F | 1/2" | 1/4" | 000000000 | 000000 |

| 3/8" | PFA Plastic | White | 125 psi @ 72° F | 5/8" | 1/4" | 000000000 | 000000 |

| 1/2" | PFA Plastic | White | 125 psi @ 72° F | 3/4" | 1/4" | 000000000 | 000000 |

| 3/4" | PFA Plastic | White | 125 psi @ 72° F | 1" | 1/4" | 000000000 | 000000 |

| 4mm | PTFE Plastic | White | 100 psi @ 72° F | 25/64" | 1/4" | 000000000 | 000000 |

| 6mm | PTFE Plastic | White | 100 psi @ 72° F | 29/64" | 1/4" | 000000000 | 000000 |

| 12mm | PTFE Plastic | White | 80 psi @ 72° F | 57/64" | 1/4" | 000000000 | 000000 |

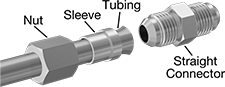

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD | Pipe Size | Material | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | 1/4 | 316 Stainless Steel | 6,000 psi @ 72° F | 1/16" | 21/64" | 000000000 | 0000000 |

| 3/8" | 3/8 | 316 Stainless Steel | 6,000 psi @ 72° F | 9/16" | 27/64" | 000000000 | 000000 |

| 1/2" | 1/2 | 316 Stainless Steel | 6,000 psi @ 72° F | 3/4" | 7/16" | 000000000 | 000000 |

| 3/4" | 3/4 | 316 Stainless Steel | 4,500 psi @ 72° F | 1 1/16" | 7/16" | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

For Tube OD | ||||

|---|---|---|---|---|

| Inch | Metric, mm | Sleeve Material | Each | |

Inch | ||||

| 1/4" | __ | 316 Stainless Steel | 000000000 | 00000 |

| 3/8" | __ | 316 Stainless Steel | 000000000 | 0000 |

| 1/2" | __ | 316 Stainless Steel | 000000000 | 00000 |

| 3/4" | __ | 316 Stainless Steel | 000000000 | 00000 |

Inch × Metric | ||||

| 1/4" | 6 | 316 Stainless Steel | 000000000 | 00000 |

| 3/8" | 10 | 316 Stainless Steel | 000000000 | 00000 |

| 1/2" | 12 | 316 Stainless Steel | 000000000 | 00000 |

37° Flared Fittings with Thread Sealant for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range:

Adapters: -420° to 450° F

Sleeves and Nuts: -420° to 1,200° F - Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPT threads meet SAE J514 only

The male pipe threads on these fittings have a sealant applied for extra protection against leaks. Also known as JIC (Joint Industrial Council) fittings, they provide a tight metal-to-metal seal on tubing that is flared to 37°. They’re often used in hydraulic applications. Made from 316 stainless steel, these fittings have excellent corrosion resistance. A complete fitting requires a nut and a sleeve (ferrule) for each tube end—tighten the nut to create a secure seal that withstands high pressure. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

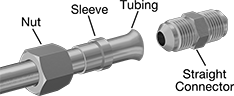

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -60° to 400° F

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.