About On/Off Valves

More

About Strainers and Selecting Screen Size

More

Low-Pressure Bronze Y-Strainers

- Max. Pressure for Water, Oil, Inert Gas, and Diesel Fuel: 200 psi @ 70° F

Max. Pressure for Steam: 125 psi @ 400° F - Temp. Range: -20° to 400° F

Install these strainers prior to valves, pumps, and nozzles to catch debris in your pipeline and protect sensitive equipment. They are designed for low-pressure applications. Strainers have a threaded drain with a plug that provides access to the screen without disconnecting your line. They are bronze for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Plug Pipe Size | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | Each | ||

With Mesh Screen | |||||||||||||

| 1/4 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | 20 | __ | 00000000 | 000000 | 000000000 | 000000 |

| 1/4 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | __ | 00000000 | 00000 | 00000000 | 00000 | |

| 3/8 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | 20 | __ | 00000000 | 00000 | 000000000 | 00000 |

| 3/8 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | __ | 00000000 | 00000 | 00000000 | 00000 | |

| 1/2 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | 20 | __ | 00000000 | 00000 | 000000000 | 00000 |

| 1/2 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 49/64" | 1 61/64" | __ | 00000000 | 00000 | 00000000 | 00000 | |

| 3/4 | NPT | 3 15/16" | 3 1/2" | 3/8 | 304 Stainless Steel | 31/32" | 2 11/32" | 20 | __ | 00000000 | 00000 | 000000000 | 00000 |

| 3/4 | NPT | 3 15/16" | 3 1/2" | 3/8 | 304 Stainless Steel | 31/32" | 2 11/32" | __ | 00000000 | 00000 | 00000000 | 00000 | |

| 1 | NPT | 4 1/2" | 4 1/2" | 1/2 | 304 Stainless Steel | 1 9/64" | 2 43/64" | 20 | __ | 00000000 | 00000 | 000000000 | 00000 |

| 1 | NPT | 4 1/2" | 4 1/2" | 1/2 | 304 Stainless Steel | 1 9/64" | 2 43/64" | __ | 00000000 | 00000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 27/64" | 3 11/64" | 20 | __ | 00000000 | 00000 | 000000000 | 00000 |

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 27/64" | 3 11/64" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 6 3/16" | 5 1/16" | 1/2 | 304 Stainless Steel | 1 49/64" | 3 37/64" | 20 | __ | 00000000 | 000000 | 000000000 | 00000 |

| 1 1/2 | NPT | 6 3/16" | 5 1/16" | 1/2 | 304 Stainless Steel | 1 49/64" | 3 37/64" | __ | 00000000 | 000000 | 00000000 | 00000 | |

| 2 | NPT | 7 7/16" | 6 1/4" | 1/2 | 304 Stainless Steel | 2 3/16" | 4 53/64" | 20 | __ | 00000000 | 000000 | 000000000 | 00000 |

| 2 | NPT | 7 7/16" | 6 1/4" | 1/2 | 304 Stainless Steel | 2 3/16" | 4 53/64" | __ | 00000000 | 000000 | 00000000 | 000000 | |

| 2 1/2 | NPT | 9" | 7 3/4" | 1/2 | 304 Stainless Steel | 2 5/8" | 5 7/16" | 20 | __ | 00000000 | 000000 | 000000000 | 000000 |

| 2 1/2 | NPT | 9" | 7 3/4" | 1/2 | 304 Stainless Steel | 2 47/64" | 5 7/16" | __ | 00000000 | 000000 | 00000000 | 000000 | |

With Perforated Screen | |||||||||||||

| 1/2 | NPT | 3 3/16" | 2 15/16" | 3/8 | 304 Stainless Steel | 3/4" | 1 15/16" | __ | 000000000 | 00000 | 000000000 | 00000 | |

| 3/4 | NPT | 3 15/16" | 3 1/2" | 3/8 | 304 Stainless Steel | 31/32" | 2 11/32" | __ | 000000000 | 00000 | 000000000 | 00000 | |

| 1 | NPT | 4 1/2" | 4 1/2" | 1/2 | 304 Stainless Steel | 1 1/8" | 2 11/16" | __ | 000000000 | 00000 | 000000000 | 00000 | |

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 7/16" | 3 3/16" | __ | 000000000 | 000000 | 000000000 | 00000 | |

| 1 1/2 | NPT | 6 3/16" | 5 1/16" | 1/2 | 304 Stainless Steel | 1 3/4" | 3 5/8" | __ | 000000000 | 000000 | 000000000 | 00000 | |

| 2 | NPT | 7 7/16" | 6 1/4" | 1/2 | 304 Stainless Steel | 2 1/8" | 4 13/16" | __ | 000000000 | 000000 | 000000000 | 00000 | |

| 2 1/2 | NPT | 9" | 7 3/4" | 1/2 | 304 Stainless Steel | 2 3/4" | 5 7/16" | __ | 000000000 | 000000 | 000000000 | 000000 | |

Medium-Pressure Bronze and Brass Y-Strainers

- Max. Pressure: See Table

- Max. Steam Pressure:

Brass: Not Rated

Bronze: 235 psi @ 400° F - Temp. Range:

Brass: 35° to 350° F

Bronze: -20° to 400° F

Strainers catch debris in your pipeline, preventing damage to valves, pumps, nozzles, and other sensitive equipment. They are designed for medium-pressure applications. Strainers have a threaded drain with a plug that provides access to the screen without disconnecting your line. They have good corrosion resistance.

Strainers with magnetic plug attract and catch ferrous particles.

Strainers for use with drinking water meet NSF/ANSI 61 safety standards for drinking water systems.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Max. Pressure | Lg. | Ht. | Plug Pipe Size | Material | Screen Material | Choose a Screen Mesh Size | Each | Each | ||

For Use With Drinking Water—NSF/ANSI 61 | ||||||||||||

| 1/2 | NPT | 400 psi @ 70° F | 2 3/4" | 2 1/4" | 1/4 | Brass | 304 Stainless Steel | 20 | 0000000 | 000000 | 0000000 | 000000 |

| 3/4 | NPT | 400 psi @ 70° F | 3 3/16" | 2 3/4" | 1/4 | Brass | 304 Stainless Steel | 20 | 0000000 | 00000 | 0000000 | 00000 |

| 1 | NPT | 400 psi @ 70° F | 3 3/4" | 3 1/4" | 1/2 | Brass | 304 Stainless Steel | 20 | 0000000 | 00000 | 0000000 | 00000 |

For Use With Water, Oil, Inert Gas, and Steam | ||||||||||||

| 1/4 | NPT | 400 psi @ 150° F | 2 3/4" | 2 5/16" | 1/8 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 3/8 | NPT | 400 psi @ 150° F | 2 3/4" | 2 5/16" | 1/8 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 1/2 | NPT | 400 psi @ 150° F | 3 1/8" | 2 11/16" | 1/8 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 3/4 | NPT | 400 psi @ 150° F | 3 1/2" | 3 1/16" | 1/4 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 1 | NPT | 400 psi @ 150° F | 4 1/8" | 3 13/16" | 1/4 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 1 1/4 | NPT | 400 psi @ 150° F | 5 1/16" | 4 3/4" | 3/8 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 1 1/2 | NPT | 400 psi @ 150° F | 5 1/2" | 5 3/8" | 1/2 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 2 | NPT | 400 psi @ 150° F | 6 5/8" | 6 7/8" | 3/4 | Bronze | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 000000 | |

Strainers | Replacement Screens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Max. Pressure | Lg. | Ht. | Plug Pipe Size | Material | Screen Material | Screen Mesh Size | Each | Each | ||

For Use With Water, Oil, Inert Gas, Acetone, Diesel Fuel, and Steam | ||||||||||||

| 1 | NPT | 400 psi @ 70° F | 4 1/8" | 4 3/8" | 1/4 | Bronze | 304 Stainless Steel | 40 | 0000000 | 0000000 | 0000000 | 000000 |

| 2 | NPT | 400 psi @ 70° F | 6 5/8" | 7 1/16" | 3/4 | Bronze | 304 Stainless Steel | 40 | 0000000 | 000000 | 0000000 | 000000 |

Compact T-Strainers

- Max. Pressure for Water: 250 psi @ 70° F

- Temp. Range: 32° to 180° F

With a smaller overall size than T-strainers of the same pipe size, these are well suited to applications in close quarters. Use them to capture debris in your pipeline before it can damage valves, pumps, nozzles, and other sensitive equipment. Unthread the retainer cap to remove debris. Strainers are bronze for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Each | Each | ||

Bronze | |||||||||||

| 1/4 | NPT | 2 1/16" | 1 11/16" | 304 Stainless Steel | 47/64" | 49/64" | 0000000 | 0000000 | 0000000 | 000000 | |

| 3/8 | NPT | 2 1/2" | 2 3/16" | 304 Stainless Steel | 25/32" | 1 1/4" | 0000000 | 000000 | 0000000 | 00000 | |

| 1/2 | NPT | 2 3/4" | 2 5/8" | 304 Stainless Steel | 25/32" | 1 35/64" | 0000000 | 000000 | 0000000 | 00000 | |

Bronze Basket Strainers

- Max. Pressure for Water, Oil, and Diesel Fuel: 200 psi @ 100° F

- Temp. Range: 20° to 200° F

These bronze basket strainers are stronger and more corrosion resistant than iron. Commonly used in high-flow industrial processes, they hold more debris than all of our other strainers. Use them in your pipeline to protect sensitive equipment such as valves, pumps, and nozzles. They have a threaded drain with a plug for easy cleaning.

Strainers with flanged pipe connections allow for easy access to your pipeline; bolt them to a flange with the same pipe size. They have brackets on the bottom so you can mount them to the floor for stability.

To Order: Choose a mesh size for a mesh basket or an opening size for a perforated basket.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Baskets | Replacement Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Gasket Material | Basket Material | Choose a Basket Mesh Size | Choose a Basket Opening Size | Each | Each | Each | |||

| 3/8 | NPT | 4 3/4" | 6 5/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 0000000 | 0000000 | 0000000 | 00000000 | 000000 | ||

| 1/2 | NPT | 4" | 6 5/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3/4 | NPT | 5 3/8" | 8 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 | NPT | 5 3/8" | 8 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 1/4 | NPT | 6 3/4" | 9 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 1/2 | NPT | 7 3/8" | 11" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 2 | NPT | 8 3/4" | 13 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 2 1/2 | NPT | 10 1/2" | 14 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3 | NPT | 11 1/2" | 17 3/4" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

Strainers | Replacement Baskets | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Ht. | Gasket Material | Basket Material | Choose a Basket Mesh Size | Choose a Basket Opening Size | Each | Each | Each | |||

| 2 | 6" | 150 | 10 1/2" | 13 3/4" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000000 | 0000000 | 0000000 | 00000000 | 000000 | ||

| 2 1/2 | 7" | 150 | 11 5/8" | 15 5/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3 | 7 1/2" | 150 | 13 1/8" | 18" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 4 | 9" | 150 | 16 3/4" | 19 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 00000000 | 00000000 | 00000 | ||

| 6 | 11" | 150 | 19 5/8" | 28 1/2" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000000 | 0000000 | 00000000 | 00000000 | 00000 | ||

Easy-Swap Bronze Basket Strainers

- Max. Pressure for Water, Oil, and Diesel Fuel: 150 psi @ 70° F

- Temp. Range: 20° to 150° F

Bronze construction gives these basket strainers better strength and corrosion resistance than iron. They have two baskets so you can divert flow to one basket while you work on the other. Turn the valve handle to direct flow. Commonly used in high-flow industrial processes, basket strainers hold more debris than all of our other strainers. Install them prior to valves, pumps, nozzles, and other sensitive equipment to catch particles in your pipeline. They have a threaded drain with a plug for easy cleaning. Mounting brackets on the bottom allow you to bolt strainers to the floor for stability.

Strainers with flanged pipe connections allow for easy access to your pipeline; bolt them to a flange with the same pipe size.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Baskets | Replacement Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Wd. | Ht. | Gasket Material | Basket Material | Choose a Basket Opening Size | Each | Each | Each | |||

| 3/4 | NPT | 6 1/8" | 10 1/2" | 10 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 0000000 | 00000000 | 000000 | |

| 1 | NPT | 5 1/2" | 10 1/2" | 10 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 8 3/4" | 13 1/4" | 12 3/4" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 7 1/2" | 13 1/4" | 12 3/4" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 2 | NPT | 10" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 2 1/2 | NPT | 10" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 000000 | 00000000 | 00000 | |

Strainers | Replacement Baskets | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Wd. | Ht. | Gasket Material | Basket Material | Choose a Basket Opening Size | Each | Each | Each | |||

| 2 | 6" | 150 | 10 5/8" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 0000000000 | 0000000 | 0000000 | 00000000 | 000000 | |

| 2 1/2 | 7" | 150 | 10 3/4" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 3 | 7 1/2" | 150 | 13 1/2" | 22 3/4" | 18" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 4 | 9" | 150 | 16" | 24 3/4" | 21 5/8" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 000000 | 00000000 | 00000 | |

Low-Pressure Inline Strainers

- Max. Pressure for Water, Oil, and Inert Gas: 250 psi @ 70° F

- Temp. Range: 32° to 180° F

Use these strainers in place of regular fittings to catch debris in low-pressure applications. The screen is in the strainer body to save space. They are bronze for good corrosion resistance. They have a threaded union pipe connection on one end, which allows you to remove debris without detaching the pipe connection.

For technical drawings and 3-D models, click on a part number.

Strainers | Replacement Screens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Material | Gasket Material | Screen Material | Screen OD | Screen Lg. | Screen Mesh Size | Each | Each | ||

With Mesh Screen | ||||||||||||

| 3/4 | NPT | 4 3/8" | Bronze | Buna-N Rubber | 304 Stainless Steel | 1 1/16" | 2 1/4" | 40 | 0000000 | 0000000 | 0000000 | 000000 |

| 1 | NPT | 4 3/8" | Bronze | Buna-N Rubber | 304 Stainless Steel | 1 1/16" | 2 1/4" | 40 | 0000000 | 000000 | 0000000 | 00000 |

Medium-Pressure Inline Strainers

- Max. Pressure for Water, Oil, and Diesel Fuel: 500 psi @ 70° F

- Temp. Range: 32° to 180° F

Use these strainers in medium-pressure applications to protect sensitive equipment from damage caused by debris. The screen is in the strainer body to save space. Strainers have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Inline Filters

Trap small particles in tubing or pipe to ensure samples are contaminant free for testing applications. Filters protect sensitive process equipment from damage caused by debris. Brass filters have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Housing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Material | Clarity | Filter Element Material | Removes Particle Size Down To, microns | Each | |

| 1/8 | NPT | 10 cfm @ 100 psi | 300 | 300° | Brass | Opaque | Bronze | 000000000 | 00000 | |

| 1/4 | NPT | 23 cfm @ 100 psi | 300 | 300° | Brass | Opaque | Bronze | 000000000 | 00000 | |

| 3/8 | NPT | 32 cfm @ 100 psi | 300 | 300° | Brass | Opaque | Bronze | 000000000 | 00000 | |

| 1/2 | NPT | 59 cfm @ 100 psi | 300 | 300° | Brass | Opaque | Bronze | 000000000 | 00000 | |

High-Pressure Inline Filters

Remove small particles in lines that reach up to 5,000 psi to protect sensitive equipment, such as hydraulic controls. These inline filters act as a secondary defense to trap particles that make it past your intake filter without adding bulk to your line.

Brass filters resist some corrosion.

Choose filters with an access port to install a new filter element without replacing the entire unit or removing it from your line. These filters take up slightly more space than those without access ports.

Brass Housing | |||||

|---|---|---|---|---|---|

| Removes Particle Size Down To, microns | Pipe Size | Max. Pressure, psi | Max. Temp., °F | Each | |

| 10 | 1/8 | 2,000 | 200° | 000000 | 000000 |

| 10 | 1/4 | 2,000 | 200° | 0000000 | 00000 |

| 15 | 1/8 | 2,000 | 200° | 0000000 | 00000 |

| 15 | 1/4 | 2,000 | 200° | 0000000 | 00000 |

| 25 | 1/8 | 2,000 | 200° | 0000000 | 00000 |

| 25 | 1/4 | 2,000 | 200° | 0000000 | 00000 |

| 100 | 1/8 | 2,000 | 200° | 0000000 | 00000 |

| 100 | 1/4 | 2,000 | 200° | 0000000 | 00000 |

| Ht. | OD | ID | Removes Particle Size Down To, microns | Material | Max. Temp., ° F | Each | |

| 3/4" | 1/2" | 3/8" | 10 | 316 Stainless Steel | 450° | 0000000 | 000000 |

Threaded On/Off Valves with Easy-Access Strainer

A built-in strainer traps debris and allows you to replace the screen without disconnecting your pipeline. These valves have a T-handle or lever that resists accidental movement when snagged or bumped. They are full port, so they do not restrict flow.

Nickel-plated brass valves are more corrosion resistant than plain brass valves.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

Valves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Screen | Replacement Screens | |||||||||

| Pipe Size | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Material | Mesh Size | End-to-End Lg. | Each | Each | ||

NPT Female × NPT Female | ||||||||||

| 1/2 × 1/2 | 600 psi @ 100° F | 150 psi @ 355° F | -40° to 365° | 304 Stainless Steel | 50 × 50 | 3 7/16" | 0000000 | 000000 | 0000000 | 00000 |

| 3/4 × 3/4 | 600 psi @ 100° F | 150 psi @ 355° F | -40° to 365° | 304 Stainless Steel | 50 × 50 | 4" | 0000000 | 00000 | 0000000 | 0000 |

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Seal Material: Buna-N Rubber

Valves | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Screen | Replacement Screens | ||||||||||

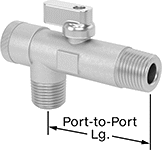

| Pipe Size | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Ball Material | Material | Mesh Size | Port-to-Port Length | Each | Each | ||

NPT Male × NPT Male | |||||||||||

| 1/2 × 1/4 | 600 psi @ 100° F | Not Rated | 0° to 200° | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 3/4" | 0000000 | 000000 | 0000000 | 00000 |

| 1/2 × 3/8 | 600 psi @ 100° F | Not Rated | 0° to 200° | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 3/4" | 0000000 | 00000 | 0000000 | 000 |

| 1/2 × 1/2 | 600 psi @ 100° F | Not Rated | 0° to 200° | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 3/4" | 0000000 | 00000 | 0000000 | 000 |

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Seal Material: Buna-N Rubber

Valves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screen | Replacement Screens | |||||||||||

| Pipe Size | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Body Material | Ball Material | Material | Mesh Size | Port-to-Port Length | Each | Each | ||

NPT Male × NPT Male | ||||||||||||

| 1/2 × 1/4 | 600 psi @ 100° F | Not Rated | 0° to 200° | Nickel-Plated Brass | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 1/16" | 000000 | 000000 | 0000000 | 00000 |

| 1/2 × 3/8 | 600 psi @ 100° F | Not Rated | 0° to 200° | Nickel-Plated Brass | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 1/16" | 0000000 | 00000 | 0000000 | 000 |

| 1/2 × 1/2 | 600 psi @ 100° F | Not Rated | 0° to 200° | Nickel-Plated Brass | Chrome-Plated Brass | 304 Stainless Steel | 50 × 50 | 2 1/16" | 0000000 | 00000 | 0000000 | 000 |