Compare over 30 copper, brass, and bronze alloys to find the right material for you—all with material certificates for traceability.

Ultra-Machinable 360 Brass Hex Bars

- Yield Strength:

Inch sizes: 25,000 psi

Metric size: 23,000 psi - Hardness:

Inch sizes: Rockwell B55-B80 (Medium)

Metric sizes: Rockwell B75 (Medium) - Temper:

Inch sizes: H02 (1/2 Hard)

Metric sizes: 1/2 Hard - Heat Treatable: No

- Specifications Met:

Inch sizes: ASTM B16

Metric sizes: European Standard EN 12164

With the highest lead content of all the brass alloys, 360 offers the best machinability. Often called free-machining and free-cutting brass, it stands up to high-speed drilling, milling, and tapping operations with minimal wear on your tools. It’s commonly used for gears, pinions, and lock components.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

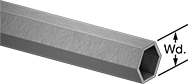

| Wd. | Wd. Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

| 1/8" | -0.006" to 0.006" | 0000000 | |||||

| 3/16" | -0.006" to 0.006" | 0000000 | |||||

| 1/4" | -0.006" to 0.006" | 0000000 | |||||

| 5/16" | -0.006" to 0.006" | 0000000 | |||||

| 3/8" | -0.006" to 0.006" | 0000000 | |||||

| 7/16" | -0.006" to 0.006" | 0000000 | |||||

| 1/2" | -0.006" to 0.006" | 0000000 | |||||

| 9/16" | -0.006" to 0.006" | 0000000 | |||||

| 5/8" | -0.006" to 0.006" | 0000000 | |||||

| 11/16" | -0.006" to 0.006" | 0000000 | |||||

| 3/4" | -0.006" to 0.006" | 0000000 | |||||

| 13/16" | -0.006" to 0.006" | 0000000 | |||||

| 7/8" | -0.006" to 0.006" | 0000000 | |||||

| 15/16" | -0.006" to 0.006" | 0000000 | |||||

| 1" | -0.006" to 0.006" | 0000000 | |||||

| 1 1/8" | -0.006" to 0.006" | 0000000 | |||||

| 1 1/4" | -0.006" to 0.006" | 0000000 | |||||

| 1 3/8" | -0.009" to 0.009" | 0000000 | |||||

| 1 1/2" | -0.009" to 0.009" | 0000000 | |||||

| 1 5/8" | -0.009" to 0.009" | 0000000 | |||||

| 1 3/4" | -0.009" to 0.009" | 0000000 | |||||

| 2" | -0.009" to 0.009" | 0000000 | |||||

| 2 1/4" | -0.009" to 0.009" | 0000000 | |||||

| 2 1/2" | -0.009" to 0.009" | 0000000 |

1 m Lg. | |||

|---|---|---|---|

| Wd., mm | Wd. Tolerance, mm | Each | |

| 4 | -0.09 to 0.09 | 0000000 | 000000 |

| 5 | -0.09 to 0.09 | 0000000 | 00000 |

| 6 | -0.09 to 0.09 | 0000000 | 00000 |

| 7 | -0.09 to 0.09 | 0000000 | 00000 |

| 8 | -0.09 to 0.09 | 0000000 | 00000 |

| 10 | -0.11 to 0.11 | 0000000 | 00000 |

| 12 | -0.11 to 0.11 | 0000000 | 00000 |

| 14 | -0.11 to 0.11 | 0000000 | 000000 |

| 17 | -0.11 to 0.11 | 0000000 | 000000 |

| 19 | -0.13 to 0.13 | 0000000 | 000000 |

| 22 | -0.13 to 0.13 | 0000000 | 000000 |

| 24 | -0.13 to 0.13 | 0000000 | 000000 |

Ultra-Formable 260 Brass Hex Tubes

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: H02 (1/2 Hard) to H03 (3/4 Hard)

- Heat Treatable: No

- Specifications Met: ASTM B135

The most formable brass we offer, 260 offers better weldability than 300 series brass but it’s not as machinable. Sometimes called cartridge brass, it's commonly used for ammunition casings, radiator components, and decorative door hardware.

For technical drawings and 3-D models, click on a part number.