Filter by

System of Measurement

Thread Size

Fastener Strength Grade/Class

Material

Threading

Specifications Met

Thread Type

Finish

Thread Fit

Thread Direction

Thread Length

Tensile Strength

Hardness

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Drive Style

Application

Performance

Movement

Overall Height

Threaded Rods

Anchor, connect, or hang components in a wide variety of applications, from mounting I-beams to suspending light fixtures.

High-Strength Steel

|

With a tensile strength of 150,000 psi, these rods are strong enough to stabilize steel frameworks and structural supports, such as I-beams. They are about 25% stronger than medium-strength steel rods. To avoid stripped threads during installation, make sure your nuts are also high-strength steel.

Steel—Best for dry environments since moisture will cause these rods to rust.

Lg., ft. | Tensile Strength, psi | Fastener Strength Grade/Class | Hardness | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2"-8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 150,000 | ASTM Grade BD | Rockwell C33 | ASTM A354 Grade BD | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium-Strength Steel

|

With tensile strengths from 110,000 psi to 125,000 psi, these rods are strong enough for most industrial applications, such as anchoring machinery and connecting pipe flanges. They are about twice as strong as low-strength steel rods. To avoid stripped threads during installation, make sure your nuts are also medium-strength steel.

Steel—Best for dry environments since moisture will cause these rods to rust.

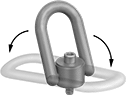

Hoist Rings—For Lifting

|

|

180° Pivot |

|

360° Swivel |

Designed for angular lifting, hoist rings resist stresses that would bend or break an eyebolt. They have a lifting ring that pivots 180° front to back and a base that swivels 360° to compensate for pitch, roll, and sway when lifting heavy or unbalanced loads. Install the base of the hoist ring flush to the mounting surface and tighten to the recommended torque that is stamped on the ring. Torque wrenches are sold separately.

Note: Capacities listed are for vertical lifting only. As the lift angle changes from vertical, the amount of weight the hoist ring can lift is significantly reduced. For example, when lifting a 1,000 lb. load at a 45° angle, you must choose a hoist ring with a capacity of at least 1,400 lbs. Do not use at an angle less than 30°.

Warning: Never use to lift people or items over people.

Machined—Machined hoist rings have a smooth finish to protect slings and hooks from damage and excess wear during lifting.

Black-Oxide Steel—Black-oxide steel hoist rings have mild corrosion resistance.

CE Marked—Hoist rings that are CE marked meet European safety standards.

Thread Size | Thread Lg. | Inside Wd. | Overall Ht. | Vert. Cap., lb. | Movement | Specs. Met | Certification | Mil. Spec. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Machined Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-8 | 2 3/4" | 4 1/2" | 15 1/4" | 24,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked | MIL-STD-1365, MIL-STD-209 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

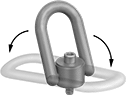

Tension-Indicating Hoist Rings—For Lifting

|

|

|

180° Pivot |

|

360° Swivel |

An indicator dot changes from red to black when these hoist rings are properly tightened, eliminating the need for a torque wrench. The dot changes back to red if the hoist ring comes loose. Ideal for angular lifting, these hoist rings withstand stresses that bend or break eyebolts. They have a lifting ring that pivots 180° front to back and a base that swivels 360° to compensate for pitch, roll, and sway when lifting heavy or unbalanced loads. A black oxide finish gives these hoist rings mild corrosion resistance.

Install the base of these hoist rings flush to your mounting surface.

Note: Capacities listed are for vertical lifting only. As the lift angle changes from vertical, the amount of weight the hoist ring can lift is significantly reduced. For example, when lifting a 1,000 lb. load at a 45° angle, you must choose a hoist ring with a capacity of at least 1,400 lbs. Do not use at an angle less than 30°.

Warning: Never use to lift people or items over people.

Hoist Rings | Replacement Bolt Kits for Hoist Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Inside Wd. | Overall Ht. | Vert. Cap., lb. | Tension Indicated, ft·lbf | Indicator Temp., ° F | Movement | Specs. Met | Certification | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Black-Oxide Steel with Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-8 | 2 3/4" | 4 1/2" | 15 1/4" | 24,000 | 800 | 0 to 165 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||