Blade-Style Cutoff and Grooving Carbide Insert Holders

Install one of these holders into a tool block for right- and left-hand mounting in a lathe. Pair with a carbide insert (sold separately) to make the exact cutoff and grooving tool you need. These holders have a tapered opening at each end.

For technical drawings and 3-D models, click on a part number.

Overall | Holders | |||||||

|---|---|---|---|---|---|---|---|---|

| Max. Dp. of Cut | Lg. | Wd. | Ht. | For Insert Thick. | Material | Insert Extractor Included | Each | |

| 1.5" | 3 3/8" | 0.063" | 3/4" | 0.087", 0.094" | Steel | Yes | 00000000 | 000000 |

| 2" | 4 5/16" | 0.063" | 1 1/32" | 0.087", 0.094" | Steel | Yes | 00000000 | 00000 |

| 3" | 4 5/16" | 0.094" | 1 1/32" | 0.122" | Steel | Yes | 00000000 | 00000 |

| 3" | 4 5/16" | 1/8" | 1 1/32" | 0.161" | Steel | Yes | 00000000 | 000000 |

| 4" | 5 7/8" | 0.094" | 1 1/4" | 0.122" | Steel | Yes | 00000000 | 000000 |

| 4" | 5 7/8" | 1/8" | 1 1/4" | 0.161", 0.187" | Steel | Yes | 00000000 | 000000 |

| 5" | 5 7/8" | 0.156" | 1 1/4" | 0.201" | Steel | Yes | 00000000 | 000000 |

| 5" | 5 7/8" | 0.203" | 1 1/4" | 0.252" | Steel | Yes | 00000000 | 000000 |

Combine a holder and carbide insert to perform cutoff and grooving tasks on a lathe.

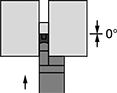

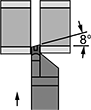

Neutral inserts have a 0° lead angle for cutting solid workpieces.

Right-hand inserts have an 8° lead angle for cutting hollow workpieces such as pipe and tubing.

C2 carbide is abrasion resistant and less likely to chip or crack than C5 carbide when cutting aluminum, brass, and bronze.

C5 carbide holds up better than C2 carbide when making cuts in steel, stainless steel, and cast iron.

Coated inserts last longer and can be run at faster speeds than uncoated inserts.

| Thick. | Groove Wd. | Lg. | Radius | For Use On | Each | |

Uncoated C2 Carbide | ||||||

|---|---|---|---|---|---|---|

Neutral | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.201" | 0.201" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.252" | 0.252" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

Right Hand | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Aluminum, Brass, Bronze | 0000000 | 00000 |

Uncoated C5 Carbide | ||||||

Neutral | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Steel | 0000000 | 00000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Steel | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.201" | 0.201" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.252" | 0.252" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

Right Hand | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Steel | 0000000 | 00000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Steel | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Steel | 0000000 | 00000 |

Titanium Nitride (TiN)-Coated C5 Carbide | ||||||

Neutral | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.201" | 0.201" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.252" | 0.252" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

Right Hand | ||||||

| 0.087" | 0.087" | 0.385" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.094" | 0.094" | 0.385" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.122" | 0.122" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.161" | 0.161" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.187" | 0.187" | 0.525" | 0.008" | Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

Mount blade-style holders to a lathe tool post or turret.

Shank | Overall | |||||||

|---|---|---|---|---|---|---|---|---|

| For Holder Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Material | Each | |

| 3 3/8" | 5/8" | 1/2" | 3" | 1" | 1 3/8" | Steel | 00000000 | 0000000 |

| 4 5/16", 4 7/16" | 3/4" | 3/4" | 3 1/2" | 1 1/2" | 2" | Steel | 00000000 | 000000 |

| 5 7/8" | 3/4" | 3/4" | 4 1/2" | 1 3/4" | 2" | Steel | 00000000 | 000000 |

| 5 7/8" | 7/8" | 1" | 4 1/2" | 2" | 2 1/8" | Steel | 00000000 | 000000 |

| 5 7/8" | 1 1/8" | 1 1/4" | 4 1/2" | 2 1/4" | 2 3/8" | Steel | 00000000 | 000000 |

Tool Blocks for Blade-Style Cutoff and Grooving Carbide Insert Holders

Mount blade-style holders to a lathe tool post or turret.

For technical drawings and 3-D models, click on a part number.

Shank | Overall | |||||||

|---|---|---|---|---|---|---|---|---|

| For Holder Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Material | Each | |

| 3 3/8" | 5/8" | 1/2" | 3" | 1" | 1 3/8" | Steel | 00000000 | 0000000 |

| 4 5/16", 4 7/16" | 3/4" | 3/4" | 3 1/2" | 1 1/2" | 2" | Steel | 00000000 | 000000 |

| 5 7/8" | 3/4" | 3/4" | 4 1/2" | 1 3/4" | 2" | Steel | 00000000 | 000000 |

| 5 7/8" | 7/8" | 1" | 4 1/2" | 2" | 2 1/8" | Steel | 00000000 | 000000 |

| 5 7/8" | 1 1/8" | 1 1/4" | 4 1/2" | 2 1/4" | 2 3/8" | Steel | 00000000 | 000000 |

Blade-Style Holders for Indexable Cutoff and Grooving Carbide Inserts

Install one of these holders into a tool block for right- and left-hand mounting in a lathe. Pair with a carbide insert (sold separately) to make the exact cutoff and grooving tool you need. These holders have an opening at each end.

Use an insert extractor (sold separately) to change out inserts in the holder.

For technical drawings and 3-D models, click on a part number.

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Dp. of Cut | Lg. | Wd. | Ht. | For Insert Thick. | Material | Insert Extractor Included | Each | |

| 1" | 4 7/16" | 0.063" | 1 1/32" | 0.079" | Steel | No | 0000000 | 0000000 |

| 1.15" | 5 7/8" | 0.063" | 1 1/4" | 0.079" | Steel | No | 0000000 | 000000 |

| 1.55" | 4 7/16" | 0.094" | 1 1/32" | 0.118" | Steel | No | 0000000 | 000000 |

| 1.65" | 4 7/16" | 1/8" | 1 1/32" | 0.157" | Steel | No | 0000000 | 000000 |

| 1.75" | 5 7/8" | 0.094" | 1 1/4" | 0.118" | Steel | No | 0000000 | 000000 |

| 1.95" | 5 7/8" | 1/8" | 1 1/4" | 0.157" | Steel | No | 0000000 | 000000 |

| 2.35" | 5 7/8" | 0.156" | 1 1/4" | 0.197" | Steel | No | 0000000 | 000000 |

| 2.75" | 5 7/8" | 0.203" | 1 1/4" | 0.236" | Steel | No | 0000000 | 000000 |

| Insert Extractor | 0000000 | Each | 000000 |

Cut square corner grooves in a workpiece or cut completely through a part. Pair an insert with a compatible holder. When the first cutting edge dulls, flip the insert to use the other edge, giving it twice the life of a standard cutoff and grooving insert.

| Thick. | Max. Dp. of Cut | Lg. | Lead Angle | Radius | Material | Material Grade | Finish | For Use On | Each | |

Neutral | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.079" | 0.04" | 0.866" | 0° | 0.079" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 000000 |

| 0.118" | 0.06" | 0.866" | 0° | 0.118" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.157" | 0.08" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.197" | 0.1" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.236" | 0.12" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

Mount blade-style holders to a lathe tool post or turret.

Cutoff Blade Holders

Place a cutoff blade into a holder to keep it firmly in place in a lathe's tool post. A set screw secures the blade into the holder. Use holders with wedge-shaped cutoff blades (sold separately) that have dimensions that correspond to the holder’s capacity.

Right-hand offset holders are good for working close to the chuck.

For technical drawings and 3-D models, click on a part number.

For Blade | Shank | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | For Lathe Swing | For Blade Bevel Angle | Wd. | Ht. | Lg. | Wd. | Material | Overall Ht. | Each | |

Neutral | |||||||||||

| 3/32" | 5/8" | 9"-10" | 10° | 3/8" | 7/8" | 5" | 3/8" | Steel | 1 1/2" | 00000000 | 000000 |

| 1/8" | 3/4" | 11"-14" | 10° | 1/2" | 1 1/8" | 6" | 1/2" | Steel | 1 3/4" | 00000000 | 00000 |

| 1/8" | 7/8" | 14"-16" | 10° | 5/8" | 1 3/8" | 7" | 5/8" | Steel | 2" | 00000000 | 00000 |

| 3/16" | 1" | 0"-16" | 10° | 3/4" | 1 5/8" | 8" | 3/4" | Steel | 2 1/4" | 00000000 | 00000 |

Right-Hand Offset | |||||||||||

| 3/32" | 5/8" | 9"-10" | 10° | 3/8" | 7/8" | 5" | 3/8" | Steel | 1 3/8" | 00000000 | 00000 |

| 1/8" | 3/4" | 11"-14" | 10° | 1/2" | 1 1/8" | 6" | 1/2" | Steel | 1 5/8" | 00000000 | 00000 |

| 1/8" | 7/8" | 14"-16" | 10° | 5/8" | 1 3/8" | 7" | 5/8" | Steel | 2" | 00000000 | 00000 |

| 3/16" | 1" | 0"-16" | 10° | 3/4" | 1 5/8" | 8" | 3/4" | Steel | 2 3/8" | 00000000 | 00000 |

Cutoff Blade Holders for Quick-Change Lathe Tool Posts

Securely hold wedge-shaped and T-shaped cutoff blades in a quick-change tool post. A height-adjustment screw allows for quick and accurate adjustment of the tool height without the need for shimming. Posts and holders (sold separately) are interchangeable with systems from Aloris, Dorian, and Armstrong. Use with cutoff blades (sold separately) that have dimensions that correspond to the holder’s capacity.

Holders | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For Blade | Replacement Height Adjustment Screws | ||||||||

| For Tool Post Series | For Lathe Swing | Height | Width | Centerline Ht. | Overall Ht. | Each | Each | ||

| AXA | 0"-10" | 1/2" | 3/32" | 13/16" | 1 1/2" | 00000000 | 0000000 | 000000000 | 000000 |

| BXA | 12"-15" | 11/16" | 1/8" | 1" | 1 3/4" | 00000000 | 000000 | 000000000 | 00000 |

| CXA | 13"-18" | 3/4" | 1/8" | 1 3/16" | 2" | 00000000 | 000000 | 000000000 | 00000 |

| CA | 14"-20" | 7/8" | 3/16" | 1 7/16" | 2 1/2" | 00000000 | 000000 | 000000000 | 00000 |

Quick-Change Lathe Tool Posts

Position and secure tools on manual and CNC lathes. Two slide-in dovetail mounts allow you to quickly change from one tool holder to another. The dovetail mounts are set 90° apart so you can mount tool holders on either side. A wedge-type locking system eliminates vibration and ensures repeated accuracy within millionths of an inch. Posts and holders (sold separately) are interchangeable with systems from Aloris, Dorian, and Armstrong.

Select the tool post series that matches your lathe’s swing and center height. Lathe swing is the maximum workpiece diameter that can be turned on the lathe. To find your lathe’s swing, measure the distance between the centerline of the lathe and the lathe bed and multiply by two. To find your lathe’s center height, measure the distance from the centerline of the lathe to the top of the compound. Choose the tool post series with an optimal center height that is closest to your lathe’s center height.

Tool posts with blank T-nut come with a T-nut that must be machined to fit your lathe’s T-slot.

Tool posts with custom T-nut come with a T-nut that has been machined to fit your lathe’s T-slot. To order: Provide the base width, base height, slot width, and overall height of your lathe’s T-slot.

For Lathe | Body | T-Nut O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool Post Series | Swing | Center Ht. | Optimal Center Ht. | Wd. | Ht. | O'all Ht. | Post Dia. | Lg. | Wd. | Ht. | Each | |

| AXA | 0"-10" | 15/16"-1 1/4" | 1 3/32" | 2 1/2" | 2 1/4" | 3 7/8" | 9/16" | 4 3/8" | 2 1/4" | 1/2" | 00000000 | 0000000 |

| BXA | 12"-15" | 1 1/8"-1 3/4" | 1 7/16" | 3" | 2 3/4" | 4 5/8" | 5/8" | 5 3/8" | 2 3/4" | 5/8" | 00000000 | 000000 |

| CXA | 13"-18" | 1 7/16"-2" | 1 23/32" | 3 1/2" | 3" | 5 1/8" | 3/4" | 6 1/8" | 3" | 3/4" | 00000000 | 000000 |

| CA | 14"-20" | 1 11/16"-2 5/8" | 2 5/32" | 4" | 3 5/8" | 6 1/4" | 7/8" | 7 3/8" | 3 1/2" | 7/8" | 00000000 | 000000 |

For Lathe | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool Post Series | Swing | Center Ht. | Optimal Center Ht. | Wd. | Ht. | O'all Ht. | Post Dia. | Choose a T-Slot Base Wd. | Choose a T-Slot Base Ht. | Choose a T-Slot Wd. | Choose a T-Slot O'all Ht. | Each | |

| AXA | 0"-10" | 15/16"-1 1/4" | 1 3/32" | 2 1/2" | 2 1/4" | 3 7/8" | 9/16" | 0"-1 1/2" | 3/16"-3/8" | 5/8"-1" | 0"-1/2" | 000000000 | 0000000 |

| BXA | 12"-15" | 1 1/8"-1 3/4" | 1 7/16" | 3" | 2 3/4" | 4 5/8" | 5/8" | 0"-2 1/4" | 3/16"-3/8" | 11/16"-1 5/8" | 0"-5/8" | 000000000 | 000000 |

| CXA | 13"-18" | 1 7/16"-2" | 1 23/32" | 3 1/2" | 3" | 5 1/8" | 3/4" | 0"-2 1/2" | 1/4"-1/2" | 13/16"-1 9/16" | 0"-3/4" | 000000000 | 000000 |

| CA | 14"-20" | 1 11/16"-2 5/8" | 2 5/32" | 4" | 3 5/8" | 6 1/4" | 7/8" | 0"-2 1/2" | 1/4"-1/2" | 15/16"-1 1/2" | 0"-7/8" | 000000000 | 000000 |

| Each | ||

AXA | ||

|---|---|---|

| Square-Shank Tool Holder | 00000000 | 000000 |

| Square- and Round-Shank Tool Holder | 00000000 | 00000 |

| Rigid-Hold Round-Shank Tool Holder | 00000000 | 000000 |

| Cutoff Blade Holder | 00000000 | 000000 |

| 5C Collet Holder | 000000000 | 000000 |

| Drill Chuck Holder | 000000000 | 000000 |

| Morse Taper 2 Holder | 000000000 | 000000 |

| Replacement Handle | 000000000 | 00000 |

| Replacement Ball for Handle | 000000000 | 0000 |

| Replacement Flange Nut | 000000000 | 00000 |

BXA | ||

| Square-Shank Tool Holder | 00000000 | 00000 |

| Square- and Round-Shank Tool Holder | 00000000 | 00000 |

| Rigid-Hold Round-Shank Tool Holder | 00000000 | 000000 |

| Cutoff Blade Holder | 00000000 | 000000 |

| 5C Collet Holder | 000000000 | 000000 |

| Drill Chuck Holder | 000000000 | 000000 |

| Morse Taper 3 Holder | 000000000 | 000000 |

| Replacement Handle | 000000000 | 00000 |

| Replacement Ball for Handle | 000000000 | 0000 |

| Replacement Flange Nut | 000000000 | 00000 |

CXA | ||

| Square-Shank Tool Holder | 00000000 | 00000 |

| Square- and Round-Shank Tool Holder | 00000000 | 000000 |

| Rigid-Hold Round-Shank Tool Holder | 00000000 | 000000 |

| Cutoff Blade Holder | 00000000 | 000000 |

| 5C Collet Holder | 000000000 | 000000 |

| Drill Chuck Holder | 000000000 | 000000 |

| Replacement Handle | 000000000 | 00000 |

| Replacement Ball for Handle | 000000000 | 0000 |

| Replacement Flange Nut | 000000000 | 00000 |

CA | ||

| Square-Shank Tool Holder | 00000000 | 000000 |

| Square- and Round-Shank Tool Holder | 00000000 | 000000 |

| Rigid-Hold Round-Shank Tool Holder | 00000000 | 000000 |

| Cutoff Blade Holder | 00000000 | 000000 |

| 5C Collet Holder | 000000000 | 000000 |

| Drill Chuck Holder | 000000000 | 000000 |

| Morse Taper 3 Holder | 000000000 | 000000 |

| Morse Taper 4 Holder | 000000000 | 000000 |

| Replacement Handle | 000000000 | 00000 |

| Replacement Ball for Handle | 000000000 | 0000 |

| Replacement Flange Nut | 000000000 | 00000 |