How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

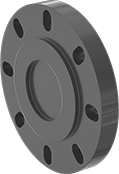

UV-Resistant Polypropylene Pipe Flanges for Chemicals

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See Table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Fittings: Use Schedule 80 Polypropylene Plastic

Use these polypropylene flanges in outdoor environments—they resist the damaging effects of ultraviolet light. Flanges have the chemical resistance to stand up to a wide variety of acids, solvents, and other harsh substances. Also known as Pressure Class 150 flanges, they have thick, strong walls for heavy duty chemical processing applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. When connecting to pipe, apply a non-hardening, plastic-compatible sealant to the male pipe threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flanged Connection Surface | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Temperature Range, °F | Each | |

NPT Threads | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Flat | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 3/4 | Flat | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 00000 |

| 1 | Flat | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 000000000 | 00000 |

| 1 1/4 | Flat | 4 1/2" | 1/2" | 5/8" | 4 | 3 1/2" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 1 1/2 | Flat | 5" | 1/2" | 5/8" | 4 | 3 7/8" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 000000000 | 00000 |

| 2 | Flat | 6" | 5/8" | 3/4" | 4 | 4 3/4" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 000000000 | 00000 |

| 3 | Flat | 7 1/2" | 5/8" | 3/4" | 4 | 6" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 000000000 | 00000 |

| 4 | Flat | 9" | 5/8" | 3/4" | 8 | 7 1/2" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

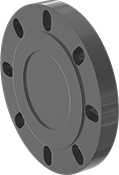

Cap flanges are also known as blind flanges.

| Pipe Size | Flanged Connection Surface | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Temperature Range, °F | Each | |

| 1/2 | Raised | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 0000000 |

| 3/4 | Raised | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 1 | Raised | 4 1/4" | 1/2" | 5/8" | 4 | 3" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 1 1/4 | Raised | 4 1/2" | 1/2" | 5/8" | 4 | 3 1/2" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 1 1/2 | Raised | 5" | 1/2" | 5/8" | 4 | 3 7/8" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 000000 |

| 2 | Flat | 6" | 5/8" | 3/4" | 4 | 4 3/4" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 00000000 | 00000 |

| 3 | Flat | 7 1/2" | 5/8" | 3/4" | 4 | 6" | Polypropylene Plastic | Black | Not Rated | 0° to 150° | 00000000 | 00000 |

| 4 | Raised | 8 7/8" | 5/8" | 3/4" | 8 | 7 1/2" | Polypropylene Plastic | Black | Not Rated | 32° to 120° | 00000000 | 000000 |

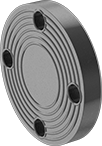

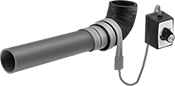

Fiberglass Pipe Flanges for Corrosive Chemicals

- For Use With: Acetic Acid (75%), Alcohol, Calcium Chloride, Chlorine, Fuel Oil, Gasoline, Hydrochloric Acid (37%), Nitric Acid (10%), Oil, Phosphoric Acid, Salt Water (30%), Sodium Hydroxide (50%), Solvents, Sulfuric Acid (70%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D4024

Flanges have excellent corrosion resistance to handle a wide range of acids and other highly-corrosive chemicals. Use in metal surface treating applications, plating solution lines, and other chemical process applications. They are reinforced with fiberglass layers for better strength and durability than any of our other pipe flanges for chemicals. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges meet ASTM D4024 specifications and testing requirements for product dimensions, performance, and material quality.

To connect flanges to pipe, first sand the inside of the flange and the end of the pipe to remove the surface finish. Next, mix the adhesive (sold separately) until the color is uniform with no streaks. Apply a thin layer of mixed adhesive to the sanded area of the pipe, approximately 1/8” thick. Repeat this process with the inside of the flange, applying a layer approximately 1/16” thick. After sealant has been applied, push the flange onto the pipe until it is fully engaged. Make sure you align the bolt holes prior to installing to minimize rotation after the flange is installed. Finally, use the adhesive-curing heat cable (sold separately) to cure the adhesive. Wrap the tape around the pipe and flange at the joint, taking care to not overlap the tape. Once you have waited the full cure time, the pipe and flange will be ready to use.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Socket Dp. | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

| 1 1/2 | 1 3/8" | 5" | 1/2" | 5/8" | 4 | 3 7/8" | Fiberglass | Black | 300 psi @ 72° F | 0000000 | 0000000 |

| 2 | 1 3/4" | 6" | 5/8" | 3/4" | 4 | 4 3/4" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 3 | 2" | 7 1/2" | 5/8" | 3/4" | 4 | 6" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 4 | 2 1/2" | 9" | 5/8" | 3/4" | 8 | 7 1/2" | Fiberglass | Black | 150 psi @ 72° F | 0000000 | 000000 |

| Pipe Cement (11.8-fl. oz. Can) | 0000000 | Each | 000000 |

Cap flanges are also known as blind flanges.

| Pipe Size | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | Fiberglass | Black | 300 psi @ 72° F | 0000000 | 0000000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | Fiberglass | Black | 150 psi @ 72° F | 0000000 | 000000 |

| Pipe Cement (11.8-fl. oz. Can) | 0000000 | Each | 000000 |

| Voltage | Max. Heat Output, °F | Lg. | Wd. | Thick. | Plug Type | Cord Lg. | Each | |

| 120V AC | 270° | 6 ft. | 1" | 1/8" | Two Prong | 6 ft. | 0000000 | 0000000 |

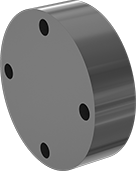

Drain, Waste, and Vent ABS Pipe Flanges for Chemicals

- For Use With: Sodium Hydroxide

- Max. Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe NIpples and Pipe: Use Schedule 40 ABS Plastic

- Fittings: Use Schedule 40 ABS Plastic

These Schedule 40 flanges are an economical choice for gravity-flow chemical waste systems. Flanges are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. They have socket-connect ends that attach to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld). They meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

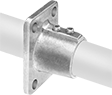

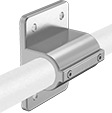

Aluminum Slip-On Framing and Fittings

Half the weight of steel, this aluminum framing resists corrosion in wet environments. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Tighten the included set screws for a secure hold.

For technical drawings and 3-D models, click on a part number.

Rail ends attach to rails on one end and have a flange on the other end to attach to floors, walls, and ceilings.

Black powder-coated aluminum blends in with backgrounds and hides dirt and grime.

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.

Flange | Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail OD | For Pipe Size | Lg. | Wd. | Dia. | Overall Ht. | No. of | Dia. | Mounting Fasteners Included | Includes | Each | |

Round Adjustable-Angle | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | __ | __ | 3 3/8" | 3 13/16" | 3 | 7/16" | No | Set Screws | 00000000 | 000000 |

| 1 7/8" | 1 1/2 | __ | __ | 3 3/8" | 4 1/8" | 3 | 7/16" | No | Set Screws | 00000000 | 00000 |

Oval | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | 5 3/4" | 2 1/2" | __ | 2 13/16" | __ | __ | No | Set Screws | 00000000 | 00000 |

| 1 7/8" | 1 1/2 | 6" | 2 3/4" | __ | 3" | __ | __ | No | Set Screws | 00000000 | 00000 |

Round | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | __ | __ | 3 1/2" | 2 7/16" | __ | __ | No | Set Screws | 00000000 | 00000 |

| 1 5/8" | 1 1/4 | __ | __ | 4 1/2" | 2 1/8" | 4 | 7/16" | No | Set Screws | 00000000 | 00000 |

| 1 7/8" | 1 1/2 | __ | __ | 3 3/4" | 2 9/16" | __ | __ | No | Set Screws | 00000000 | 00000 |

Triangular | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | 3 7/8" | 4 1/4" | __ | 2 1/2" | 3 | 7/16" | No | Set Screws | 00000000 | 00000 |

| 1 7/8" | 1 1/2 | 4 1/2" | 4 7/16" | __ | 2 3/4" | 3 | 7/16" | No | Set Screws | 00000000 | 00000 |

Through-hole fittings allow rails to run all the way through.

Rail supports secure long runs of railing.Black powder-coated aluminum blends in with backgrounds and hides dirt and grime.

Fittings that meet UL 2703 are approved for use in solar rack mounting systems.

Flange | Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail OD | For Pipe Size | Lg. | Wd. | Overall Ht. | No. of | Dia. | Mounting Fasteners Included | Includes | Specifications Met | Each | |

Flush | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | 4 1/16" | 2 15/16" | 2 1/8" | 4 | 7/16" | No | Set Screws | UL 2703 | 00000000 | 000000 |

| 1 7/8" | 1 1/2 | 4 5/16" | 3 1/8" | 2 1/2" | 4 | 7/16" | No | Set Screws | UL 2703 | 00000000 | 00000 |

Offset | |||||||||||

Black Powder-Coated Aluminum | |||||||||||

| 1 5/8" | 1 1/4 | 5 1/2" | 4" | 2 7/8" | 4 | 7/16" | No | Set Screws | __ | 00000000 | 00000 |

| 1 7/8" | 1 1/2 | 5 1/2" | 4 1/2" | 2 7/8" | 4 | 7/16" | No | Set Screws | __ | 00000000 | 00000 |

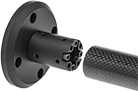

Carbon Fiber Slip-On Framing and Fittings

Stronger than plastic and aluminum, this is the lightest weight framing we offer. It has good resistance to chemicals and salt water. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Drill rails and connect fittings with the included hardware.

For technical drawings and 3-D models, click on a part number.

Rail end attaches to a rail on one end and has a flange on the other end to attach to floors, walls, and ceilings.

Flange | Mouting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Rail ID | Dia. | Thick. | Bolt Circle Dia. | Material | No. of | Dia. | Mounting Fasteners Included | Includes | Each | |

| 1 1/2" | 3 3/4" | 3/8" | 2 3/4" | Black Anodized Aluminum | 4 | 7/32" | No | Connecting Hardware | 0000000 | 000000 |

Clamp-On Framing and Fittings

Fittings come in two pieces to clasp over rails, making assembly and disassembly quicker than our other framing. Use it to form temporary partitions, modular conveyors, and workstations. To assemble, clamp fittings onto the rail and tighten the included cap screw and nut. For permanent connections and added strength, fittings have a 5/32" hole to drill in an additional screw (not included).

For technical drawings and 3-D models, click on a part number.

Rail ends attach to rails on one end and have a flange on the other end to attach to surfaces such as floors, walls, and ceilings.

Rail supports help secure long runs of railing without the need for additional posts.

For Rail OD | Black Painted Steel | ||||

|---|---|---|---|---|---|

| Clamp-On Framing Component Shape | Inch | Metric, mm | No. of Through Holes | Each | |

| Straight | 1.08" | 28 | 2 | 0000000 | 00000 |

Press-Fit Framing and Fittings

No need for fasteners—friction holds this framing together. Use press-fit framing and fittings to assemble carts, enclosures, and partitions.

For technical drawings and 3-D models, click on a part number.

Rail ends attach to rails on one end and have a flange on the other end to attach to floors, walls, and ceilings. 6”- and 12”-tall rail ends require a connector.