Filter by

Length

Material

Outside Height

Wall Thickness

Outside Width

Rail Height

Inside Width

Inside Height

Thickness

Finish

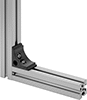

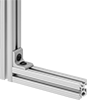

T-Slotted Framing Component

DFARS Specialty Metals

Raw Materials

Building and Machinery Hardware

Fastening and Joining

Facility and Grounds Maintenance

Containers, Storage, and Furniture

Measuring and Inspecting