About Plastic

More

About Ball and Roller Bearings

More

About Plain Bearings

More

About Linear Bearings

More

Stainless Steel Ball Bearings

Bearings are 440C stainless steel for good corrosion resistance.

Shielded bearings block out dust and other contaminants, but do not dissipate heat as efficiently as open bearings.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

| 683-2Z | 3mm | 7mm | 3mm | 440C Stainless Steel | 70 | 20 | 75,000 | Lubricated | -40° to 240° | ABEC-5 | 00000000 | 00000 |

Permanently Lubricated Stainless Steel Ball Bearings

A solid polymer lubricant surrounds the balls, eliminating the need for additional lubrication. The solid lubricant blocks out water and dust, extending the life of the bearing.

Sealed bearings have even better resistance to dust and contaminants than open bearings.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

Open | ||||||||||||

| 683 | 3 | 7 | 2 | 440C Stainless Steel | 35 | 10 | 60,000 | Lubricated | -10° to 200° | ABEC-1 | 00000000 | 000000 |

Sealed | ||||||||||||

| 683-2RS | 3 | 7 | 3 | 440C Stainless Steel | 35 | 10 | 60,000 | Lubricated | -10° to 200° | ABEC-1 | 00000000 | 00000 |

Precision Stainless Steel Ball Bearings

Made to tight tolerances, these 440C stainless steel bearings combine speed and accuracy with corrosion resistance.

Shielded bearings block out dust and other contaminants, but do not dissipate heat as efficiently as open bearings.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

Shielded | |||||||||||

| 3mm | 7mm | 3mm | 440C Stainless Steel | 55 | 14 | 80,000 | Lubricated | -30° to 280° | ABEC-7 | 0000000 | 000000 |

Flanged Ball Bearings

The flange ensures proper positioning inside a tube or housing.

440C stainless steel bearings are more corrosion resistant than steel bearings.

Open bearings dissipate heat more efficiently than shielded and sealed bearings.

Shielded bearings block out dust and other contaminants, but do not dissipate heat as efficiently as open bearings.

For technical drawings and 3-D models, click on a part number.

Flange | Radial Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia. | For Housing ID | Wd. | OD | Thick. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

| 74 | 4mm | 7mm | 2mm | 8.2mm | 0.6mm | 440C Stainless Steel | 50 | 20 | 82,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 000000 |

| 74 | 4mm | 7mm | 2mm | 8.2mm | 0.6mm | Steel | 60 | 25 | 82,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 00000 |

| 683 | 3mm | 7mm | 2mm | 8.1mm | 0.8mm | 440C Stainless Steel | 50 | 20 | 88,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 00000 |

Flange | Radial Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia. | For Housing ID | Wd. | OD | Thick. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

| 74-2Z | 4mm | 7mm | 2.5mm | 8.2mm | 0.6mm | 440C Stainless Steel | 40 | 15 | 71,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 000000 |

| 74-2Z | 4mm | 7mm | 2.5mm | 8.2mm | 0.6mm | Steel | 60 | 25 | 71,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 00000 |

| 683-2Z | 3mm | 7mm | 3mm | 8.1mm | 0.8mm | 440C Stainless Steel | 50 | 20 | 74,000 | Lubricated | -50° to 300° | ABEC-3 | 000000000 | 00000 |

Ultra-Low-Friction Dry-Running Sleeve Bearings

Use these bearings in applications with frequent starts and stops because they operate with very little friction.

Thermoplastic-blend bearings create the least amount of friction of any bearings that we offer. They handle heavier loads than PTFE and Rulon J bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

Oil-Embedded Flanged Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They’re flanged, so they handle loads both parallel and perpendicular to the shaft. They’re also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

Metric 841 Bronze Bearings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For 4mm Shaft Dia. | ||||||||||

| 7mm | 6mm | 9mm | 1.5mm | 70 lbs. @ 120 rpm | 155 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 000000 |

For 5mm Shaft Dia. | ||||||||||

| 7mm | 3mm | 11mm | 1mm | 46 lbs. @ 120 rpm | 230 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 7mm | 5mm | 11mm | 1mm | 75 lbs. @ 120 rpm | 230 lbs. @ 120 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

Light Duty Dry-Running Flanged Sleeve Bearings

Use where high loads and speeds are not required.

Thermoplastic-blend bearings have low moisture absorption and create very low friction in applications with light loads, and frequent starts and stops.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Color | Temperature Range, °F | Each | |

Thermoplastic-Blend Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 5mm Shaft Dia. | |||||||||

| 7mm | 3mm | 11mm | 1mm | 36 lbs. @ 120 rpm | 80 lbs. @ 120 rpm | Yellow | -50° to 190° | 00000000 | 00000 |

| 7mm | 5mm | 11mm | 1mm | 60 lbs. @ 120 rpm | 80 lbs. @ 120 rpm | Yellow | -50° to 190° | 00000000 | 0000 |

Ultra-Low-Friction Dry-Running Flanged Sleeve Bearings

Use these bearings in applications with frequent starts and stops because they operate with very little friction.

Thermoplastic blend bearings create the least amount of friction of any bearing that we offer. They handle heavier loads than PTFE and Rulon J bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Color | Temperature Range, °F | Each | |

Thermoplastic Blend Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 5 mm Shaft Dia. | |||||||||

| 7mm | 5mm | 11mm | 1mm | 85 lbs. @ 120 rpm | 120 lbs. @ 120 rpm | Yellow | -55° to 190° | 0000000 | 00000 |

Linear Ball Bearings

Bearings are for use with round end-supported shafts. To install, slide bearings into a housing (not included).

Bearings with stainless steel balls are more corrosion resistant than bearings with steel balls.

Fixed-alignment bearings are for use where shaft misalignment is unlikely.

For technical drawings and 3-D models, click on a part number.

Load Capacity, lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Overall Lg., mm | For Housing ID, mm | With End Seals | Dynamic | Static | Temperature Range, °F | For Shaft Material | Each | |

440C Stainless Steel Bearings with Stainless Steel Balls | |||||||||

| 3 | 10 | 7.000 - 7.015 | No | 15 | 20 | -4° to 176° | Stainless Steel, Steel | 00000000 | 000000 |

Steel Bearings with Steel Balls | |||||||||

| 3 | 10 | 7.000 - 7.015 | No | 15 | 20 | -4° to 176° | Stainless Steel, Steel | 00000000 | 00000 |

High-Temperature Linear Ball Bearings

The choice for low-friction motion in high-temperature environments. Bearings are for use with round end-supported shafts and have a fixed-alignment design for applications where shaft misalignment is unlikely. To install, slide bearings into a housing (not included).

For technical drawings and 3-D models, click on a part number.

Load Capacity, lbs. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Diameter, mm | Overall Lg., mm | For Housing ID, mm | With End Seals | Dynamic | Static | Dynamic Load Capacity at Maximum Temperature | Temperature Range, ° F | For Shaft Material | Each | |

Steel Bearings with Steel Balls | ||||||||||

| 3 | 10 | 7.000 - 7.015 | No | 15 | 20 | 15 lbs. @ 230° F | -4° to 230° | Stainless Steel, Steel | 00000000 | 000000 |

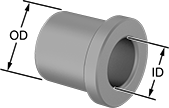

Metric Press-Fit Drill Bushings

Also known as jig bushings, these metric drill bushings fit inside fixture plate holes to guide drill bits, counterbores, reamers, and other cutting tools. They improve accuracy so that your drilled holes and cuts are consistent from part to part. Known for their versatility, drill bushings are also used as spacers, shims, and machinery bushings. These bushings are made of hardened, ground steel that holds its shape and resists wear, so they last for many cycles without needing to be replaced.

All bushings have a chamfer on the outside that centers the bushing as you place it into the hole. Press into place with a manual or hydraulic press. They also have internal chamfers, so it's easier to insert bits, pins, and punches into the bushing. Some bushings have internal chamfers on both ends, so no matter which end of the bushing is inserted into your jig, your bits, pins, and other tooling enter easily. Having an internal chamfer on the bottom of your bushing may cause shavings to get caught and bind as you remove the bit, however.

DIN 179 bushings meet dimensional and material standards that make sure they're compatible with other parts and tools. Although DIN 179 is no longer an active standard, it's still a common reference point for designers.

Don't see the size you need? Additional sizes are available.

For technical drawings and 3-D models, click on a part number.

Tolerance | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | Internal Chamfer | For Drill Bit Size | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

3.3 mm ID | ||||||||||||||

| 7 | 8 | One End | 3.30 mm | 0.004 to 0.012 | 0.023 to 0.032 | -0.01 to 0.254 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 00000 | 00000 |

| 7 | 12 | One End | 3.30 mm | 0.004 to 0.012 | 0.023 to 0.032 | -0.01 to 0.254 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

| 7 | 16 | One End | 3.30 mm | 0.004 to 0.012 | 0.023 to 0.032 | -0.01 to 0.254 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

3.4 mm ID | ||||||||||||||

| 7 | 8 | One End | 3.4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 0000 | 0000 | 0000 |

| 7 | 12 | One End | 3.4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 0000 | 0000 | 0000 |

3.5 mm ID | ||||||||||||||

| 7 | 8 | Both Ends | 3.5 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

| 7 | 8 | One End | 3.5 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 0000 | 0000 | 0000 |

| 7 | 12 | One End | 3.5 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.4 to 0.4 | PM | Steel | Rockwell C61 | __ | 0000000 | 0000 | 0000 | 0000 |

| 7 | 16 | One End | 3.5 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 00000 | 00000 | 0000 |

3.6 mm ID | ||||||||||||||

| 7 | 12 | Both Ends | 3.6 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

| 7 | 12 | One End | 3.6 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.25 to 0.25 | PM | Steel | Rockwell C61 | DIN 179 | 00000000 | 00000 | 00000 | 0000 |

| 7 | 16 | Both Ends | 3.6 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 00000 | 00000 |

| 7 | 16 | One End | 3.6 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 00000 | 00000 | 0000 |

3.7 mm ID | ||||||||||||||

| 7 | 8 | Both Ends | 3.7 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

3.9 mm ID | ||||||||||||||

| 7 | 8 | One End | 3.9 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 0000 | 0000 | 0000 |

| 7 | 12 | One End | 3.9 mm | 0.004 to 0.012 | 0.01 to 0.019 | -0.4 to 0.4 | PM | Steel | Rockwell C61 | __ | 00000000 | 0000 | 0000 | 0000 |

Tolerance | Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | Internal Chamfer | For Drill Bit Size | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

4 mm ID | ||||||||||||||

| 7 | 8 | Both Ends | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 00000 | 00000 |

| 7 | 8 | One End | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.25 to 0.25 | PM | Steel | Rockwell C61 | DIN 179 | 00000000 | 00000 | 00000 | 0000 |

| 7 | 12 | Both Ends | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 0000 | 0000 | 0000 |

| 7 | 12 | One End | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 0000000 | 0000 | 0000 | 0000 |

| 7 | 16 | Both Ends | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 00000 | 00000 |

| 7 | 16 | One End | 4 mm | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 00000 | 00000 | 0000 |

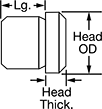

Metric Press-Fit Drill Bushings with Head

Even under extreme drilling pressure, these metric bushings won't press through your jig plate. A flanged head on the top of the bushing acts as a stop, preventing it from moving as you push down your drill bit, reamer, or other cutting bit. Drill bushings ensure accurate, consistent cuts and drilled holes from one part to the next. They sometimes also work as spacers, shims, and machinery bushings. Made of hardened, ground steel, these bushings hold their shape and resist wear over time. The flanged head protects your jig plate from damage caused by heavy use.

Although it's no longer an active standard, DIN 172 is still a common reference point for making sure parts are compatible with other parts and tools.

These bushings work in both countersunk and standard drill holes. To install, place the bushing inside the hole in your jig. A chamfered edge on the bottom of the bushing helps center the bushing in the hole. Once centered, press the bushing into the hole with a hydraulic or lever press.

For technical drawings and 3-D models, click on a part number.

Head | Tolerance | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | OD, mm | Thick., mm | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

3.4 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 000000 | 00000 | 00000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

3.5 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

3.6 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

3.7 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

3.8 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

3.9 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

4 mm ID | ||||||||||||||

| 7 | 5.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 0000 | 0000 |

| 7 | 9.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 0000 |

| 7 | 13.5 | 10 | 2.5 | 0.01 to 0.022 | 0.01 to 0.019 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

Clear Impact-Resistant Polycarbonate Tubes

- Color: Clear

- Temperature Range: -40° to 200° F

- Tensile Strength: 8,900-9,500 psi (Good)

- Impact Strength: 12-18 ft.-lbs./in. (Excellent)

- Hardness: Rockwell R118 (Hard)

- For Use Outdoors: No

Comparable to Lexan, Hyzod, Tuffak, and Makrolon, these polycarbonate tubes are half the weight of glass and maintain excellent impact resistance across a wide temperature range. Use them to make instrument gauge covers and display racks.

For technical drawings and 3-D models, click on a part number.

8 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

| OD, mm | OD Tolerance, mm | ID, mm | ID Tolerance, mm | Specifications Met | Each | |

1.5 mm Wall Thick. (-0.13 mm to 0.13 mm) | ||||||

| 7 | -0.130 to 0.130 | 4 | -0.130 to 0.130 | FDA Compliant 21 CFR 177.1580, UL 94 HB | 00000000 | 00000 |

2 mm Wall Thick. (-0.26 mm to 0.26 mm) | ||||||

| 7 | -0.130 to 0.130 | 3 | -0.130 to 0.130 | FDA Compliant 21 CFR 177.1580, UL 94 HB | 00000000 | 0000 |