Filter by

System of Measurement

OD

Material

Shape

Screw Size

For Bearing ID

For Bearing OD

Magnetic Properties

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

For Use With

Sold As

Minimum Hardness

Shoulder Diameter

Application

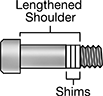

Shims for Lengthening Screw Shoulders

|

When shoulders come up short, use these shims to extend the shoulder length on your screw. Wiggle the shims over the threads and up to the existing shoulder to create the exact shoulder length you need. Use them to create more space for bearings, pulleys, and sprockets, or extend the length of travel along the shoulder.

You can stack multiple shims to achieve the exact shoulder length or space you need.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these shims won't degrade when exposed to harsh weather, salt water, and most chemicals.

Thk. | Thk. Tolerance | For Screw Size | ID | ID Tolerance | OD | OD Tolerance | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/16" Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | No. 8 | 0.146" | 0" to 0.011" | 0.178" | -0.002" to 0.002" | Rockwell B70 | 10 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/16" Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | No. 8 | 0.146" | 0" to 0.011" | 0.178" | -0.002" to 0.002" | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shims for Ball Bearing Outer Rings

|

Boost bearing efficiency and lifespan. Often used on motor shafts, these shims evenly distribute the load between multiple bearings by creating space between their outer rings. This prevents excessive pressure on any single bearing, maintaining proper alignment for smooth operation and reduced wear.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these shims won't degrade when exposed to harsh weather, salt water, and most chemicals.

Brass—With a warm, polished look, these shims are often chosen for their appearance. Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments.

For Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | ID | OD | ID | ID Tolerance | OD | OD Tolerance | Min. Hardness | Choose a Thickness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1 | 0.055" | 3/16" | 0.123" | 0" to 0.005" | 0.178" | -0.005" to 0" | Rockwell B70 | 0.003" , 0.005" , 0.007" , 0.01" , 0.02" | 25 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1 | 0.055" | 3/16" | 0.123" | 0" to 0.005" | 0.178" | -0.005" to 0" | Rockwell B90 | 0.005" , 0.007" , 0.01" , 0.02" | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1 | 0.055" | 3/16" | 0.123" | 0" to 0.005" | 0.178" | -0.005" to 0" | Rockwell B70 | 0.003" , 0.005" , 0.007" , 0.01" , 0.02" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||