About Rod Ends

More

About Ball and Roller Bearings

More

About Plain Bearings

More

Light Duty Ball Bearings

Use these bearings where high speed and precision are not a concern.

Shielded bearings block out dust and other contaminants, but do not dissipate heat as efficiently as open bearings.

Sealed bearings block out dust and other contaminants better than open and shielded bearings, but retain the most heat.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

Shielded | ||||||||||||

| 3022-2Z | 9/16" | 1 3/8" | 7/16" | Steel | 940 | 850 | 2,500 | Lubricated | -20° to 250° | Not Rated | 0000000 | 000000 |

Sealed | ||||||||||||

| 3022-2RS | 9/16" | 1 3/8" | 7/16" | Steel | 940 | 850 | 2,500 | Lubricated | -20° to 250° | Not Rated | 0000000 | 00000 |

Set Screw Collar Ball Bearings

Slip these bearings onto a shaft and secure with the included set screws, no special tools required. All have an extended inner ring for additional shaft support.

Sealed bearings block out dust and other contaminants better than shielded bearings.

Bearings with a retaining ring have a removable retaining ring that holds the bearing inside a housing.

For technical drawings and 3-D models, click on a part number.

Inner Ring | Retaining Ring | Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia. | For Housing ID | Wd. | OD | Wd. | OD | Thick. | Dynamic | Static | Max. Speed, rpm | Temp. Range, °F | ABEC Rating | Each | |

Sealed (Lubricated) | ||||||||||||||

Steel—With Retaining Ring | ||||||||||||||

| 7609-2RS | 9/16" | 1 3/4" | 5/8" | 1.009" | 1.092" | 1.922" | 0.042" | 2,550 | 1,000 | 5,000 | -20° to 250° | Not Rated | 0000000 | 000000 |

One-Piece Thrust Ball Bearings

In addition to handling higher loads than three-piece ball bearings, one-piece bearings are easier to handle. They have an outer band that holds the bearing together and acts as a shield against dust and other contaminants.

For technical drawings and 3-D models, click on a part number.

Thrust Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Thick. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | Features | Each | |

Shielded | |||||||||||

| 9/16" | 1 7/32" | 9/16" | Steel | 3,850 | 5,600 | 7,000 | Required | -40° to 245° | Lubrication Hole | 00000000 | 000000 |

Needle-Roller Bearings

Also known as drawn-cup roller bearings, these are our thinnest roller bearings. The outer ring is drawn out to form a lip that holds the bearing together. Bearings take on the shape of their housing and may be oblong prior to installation.

Open bearings dissipate heat more efficiently than sealed bearings.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | For Shaft Surface Smoothness (Ra), microinch | Temp. Range, °F | Specifications Met | Each | |

Open | ||||||||||||

| 9/16" | 3/4" | 1/2" | Steel | 1,700 | 2,420 | 17,600 | Required | 8 | -20° to 280° | DIN 281, ISO 76 | 00000000 | 00000 |

| 9/16" | 3/4" | 5/8" | Steel | 2,100 | 3,150 | 17,600 | Required | 8 | -20° to 280° | DIN 281, ISO 76 | 00000000 | 0000 |

Oil-Embedded Sleeve Bearings

Startup friction causes these bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 9/16" Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 11/16" | 7/16" | 490 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 00000 |

| 11/16" | 1/2" | 560 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 11/16" | 5/8" | 700 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 11/16" | 3/4" | 840 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 11/16" | 1" | 1,100 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 11/16" | 1 1/4" | 1,400 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 1/2" | 560 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 5/8" | 700 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 3/4" | 840 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 1" | 1,100 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 1 1/4" | 1,400 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

| 3/4" | 1 3/8" | 1,500 lbs. @ 60 rpm | Lubricated | SAE 30 Oil | -35° to 300° | 00000000 | 0000 |

High-Load Oil-Embedded Sleeve Bearings

Increased iron content makes these bearings stronger and more resistant to shock loads than standard oil-embedded bearings; however they operate at lower speeds. Startup friction causes them to release a thin layer of oil on the bearing’s surface. Color is silver because of the iron. These bearings are also magnetic due to the high iron content.

863 iron-copper bearings are also known as Super Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication | Lubricant | Temperature Range, °F | Each | |

For 9/16" Shaft Dia. | |||||||

|---|---|---|---|---|---|---|---|

| 3/4" | 1/2" | 1,100 lbs. @ 60 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 00000 |

| 3/4" | 3/4" | 1,650 lbs. @ 60 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 0000 |

| 3/4" | 1" | 2,200 lbs. @ 60 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 0000 |

| 3/4" | 1 1/4" | 2,750 lbs. @ 60 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 0000 |

| 3/4" | 1 3/8" | 3,050 lbs. @ 60 rpm | Lubricated | SAE 90 Oil | -15° to 300° | 00000000 | 0000 |

Multipurpose Sleeve Bearings

These 932 bearing bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Dynamic Radial Load Capacity | Lubrication | Temperature Range, °F | Each | |

932 Bearing Bronze Bearings | ||||||

|---|---|---|---|---|---|---|

For 9/16" Shaft Dia. | ||||||

| 3/4" | 1/2" | 1,100 lbs. @ 60 rpm | Required | -350° to 450° | 00000000 | 00000 |

| 3/4" | 3/4" | 1,650 lbs. @ 60 rpm | Required | -350° to 450° | 00000000 | 0000 |

| 3/4" | 1" | 2,250 lbs. @ 60 rpm | Required | -350° to 450° | 00000000 | 0000 |

| 3/4" | 1 1/4" | 2,800 lbs. @ 60 rpm | Required | -350° to 450° | 00000000 | 0000 |

| 3/4" | 3" | 6,750 lbs. @ 60 rpm | Required | -350° to 450° | 000000 | 00000 |

Oil-Embedded Thrust Bearings

Startup friction causes these porous bronze bearings to release a thin layer of oil on the bearing’s surface. They are also known as Oilite® bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

High-Load Ultra-Low-Friction Oil-Embedded Thrust Bearings

Handle heavy loads that frequently start and stop along shafts—these bearings contain extra iron and slippery PTFE lubricant. Startup friction causes a thin layer of PTFE to release onto the surface. Thanks to their high iron content, they also resist failing if their load suddenly and drastically increases, but they won’t run as fast as standard bearings. They’re thrust bearings, which means they support loads parallel to the shaft.

For technical drawings and 3-D models, click on a part number.

High-Load Dry-Running Thrust Bearings

A steel backing adds strength to these slippery PTFE bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD | Thick. | Dynamic Thrust Load Capacity | Temperature Range, °F | Each | |

Steel-Backed PTFE Plastic Bearings | |||||

|---|---|---|---|---|---|

For 9/16" Shaft Dia. | |||||

| 1" | 1/16" | 3,450 lbs. @ 60 rpm | -320° to 530° F° | 0000000 | 00000 |

Corrosion-Resistant Thrust Bearings

The addition of iron and aluminum gives these bearings high strength and excellent corrosion resistance—making them suitable for use in marine and mining applications.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| OD | Thick. | Dynamic Thrust Load Capacity | Lubrication | Temperature Range, °F | Each | |

954 Aluminum-Bronze Bearings | ||||||

|---|---|---|---|---|---|---|

For 9/16" Shaft Dia. | ||||||

| 1 1/4" | 1/8" | 4,400 lbs. @ 60 rpm | Required | -350° to 500° | 0000000 | 000000 |

Multipurpose Thrust Bearings

These 932 bearing bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

Low-Profile Mounted Ball Bearings

Designed with a thin, compact housing, these bearings are good for space-constrained applications.

Sealed bearings block out dust and other contaminants better than shielded bearings.

Shielded bearings dissipate heat more efficiently than sealed bearings.

For technical drawings and 3-D models, click on a part number.

Overall | Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Center Ht. | Ht. | Lg. | Wd. | Hole Ctr.-to-Ctr. | Dynamic | Static | Max. Speed, rpm | Temp. Range, °F | Alignment Style | Lubrication | Each | |

Sealed 440C Stainless Steel Bearings with Aluminum Housing | |||||||||||||

Shaft Mount Type: Press Fit | |||||||||||||

| 9/16" | 1" | 1 61/64" | 4 1/32" | 41/64" | 3 1/8" | 480 | 280 | 2,500 | 0° to 230° | Fixed Alignment | Lubricated | 0000000 | 000000 |

Overall | Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Center Ht. | Ht. | Lg. | Wd. | Hole Ctr.-to-Ctr. | Dynamic | Static | Max. Speed, rpm | Temp. Range, °F | Alignment Style | Lubrication | Each | |

Shielded 440C Stainless Steel Bearings with Aluminum Housing | |||||||||||||

Shaft Mount Type: Press Fit | |||||||||||||

| 9/16" | 1" | 1 61/64" | 4 1/32" | 41/64" | 3 1/8" | 480 | 280 | 5,000 | -30° to 300° | Fixed Alignment | Lubricated | 00000000 | 000000 |

Swivel Joints

Also known as spherical bearings, swivel joints support angular misalignment. Press them into a hole or housing where a ball joint rod end won’t fit. They need to be lubricated when first installed and periodically after that. Apply any type of bearing grease to the ball, and rotate it to work it into the races.

For technical drawings and 3-D models, click on a part number.

| ID | OD | O'all Thick. | Housing Thick. | Max. Ball Swivel | Static Radial Load Cap., lbs. | Material | Each | |

Open | ||||||||

|---|---|---|---|---|---|---|---|---|

| 9/16” | 1 3/32" | 9/16" | 7/16" | 19° | 24,900 | Alloy Steel | 00000000 | 00000 |

Lubrication-Free Swivel Joints

A slippery PTFE liner reduces friction without the oily mess. Also known as spherical bearings, they support angular misalignment. Press them into a hole or housing where a ball joint rod end won’t fit.

For technical drawings and 3-D models, click on a part number.

| ID | OD | O'all Thick. | Housing Thick. | Max. Ball Swivel | Static Radial Load Cap., lbs. | Temp. Range, °F | Material | Each | |

| 9/16" | 1 3/32" | 9/16" | 7/16" | 19° | 24,900 | -65° to 275° | Alloy Steel | 00000000 | 000000 |

Corrosion-Resistant Swivel Joints

Stronger than plastic models, these stainless steel swivel joints are also more corrosion resistant than steel joints. Ball is heat treated for strength. Also known as spherical bearings, they support angular misalignment. Press them into a hole or housing where a ball joint rod end won’t fit. They don't come lubricated, so you'll need to lubricate during installation and on an ongoing basis.

For technical drawings and 3-D models, click on a part number.

| ID | OD | O'all Thick. | Housing Thick. | Max. Ball Swivel | Static Radial Load Cap., lbs. | Material | Each | |

| 9/16" | 1 3/32" | 9/16" | 7/16" | 19° | 23,700 | 303 Stainless Steel | 00000000 | 000000 |

Press-Fit Drill Bushings

Mount flush with jig plates for precise drilling. These bushings can also be used as spacers, shims, and machinery bushings.

Don't see the size you need? Additional sizes are available.

For technical drawings and 3-D models, click on a part number.

Tolerance | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | 1-5 | 6-11 | 12-Up | |

0.5625" ID | ||||||||||||

| 3/4" | 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 7/8" | 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 0000 |

| 7/8" | 5/8" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 0000 |

| 7/8" | 3/4" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 0000 |

| 7/8" | 1" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 7/8" | 1 1/4" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 7/8" | 1 3/8" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 7/8" | 1 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 7/8" | 1 3/4" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 7/8" | 2 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 1" | 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 1" | 5/8" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 1" | 3/4" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 1" | 1" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 1" | 1 1/4" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 1" | 1 3/8" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 1" | 1 1/2" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 1" | 2 1/8" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 1" | 3" | 9/16" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

Press-Fit Drill Bushings with Head

The head prevents these bushings from being pushed through the jig when drilling pressure is extreme. The head sits above the jig plate or can be mounted flush by installing in a counterbored hole. Drill bushings can also be used as spacers, shims, and machinery bushings.

Don't see the size you need? Additional sizes are available.

For technical drawings and 3-D models, click on a part number.

Head | Tolerance | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | OD | Thick. | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | 1-5 | 6-11 | 12-Up | |

0.5625" ID | ||||||||||||||

| 7/8" | 1/2" | 9/16" | 1 7/64" | 1/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.015" to 0.015" | H | Steel | Rockwell C61 | 00000000 | 000000 | 000000 | 000000 |

Removable Drill Bushings

Replace worn bushings and quickly change IDs without needing to repeatedly use a lever press. Instead of pressing bushings in and out of your jig fixture, which can cause damage, these bushings slide in and out of sleeves (sold separately). By swapping in a bushing with a different ID, you can change the size of your bit and still use the same hole in your fixture. All are made to tight dimensional tolerances for consistent, accurate results, even as you change them in and out. They're also known as slip-fixed and renewable bushings.

Choose a sleeve with a length that matches the length of your bushing. To prevent bushings from spinning inside the sleeve as you drill, pair a standard sleeve with a lock screw, or use a locking sleeve.

Lock screws thread into a hole in your jig. The head of the screw fits into a notch on the bushing's head, which keeps the bushing from spinning.

For additional sizes, see Made-to-Order Removable Drill Bushings.

For technical drawings and 3-D models, click on a part number.

Head | Tolerance | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | OD | Thick. | Lock Screw/Bushing Ctr.-to-Ctr. | ID | OD | Lg. | Drill Bushing Type | Material | 1-5 | 6-11 | 12-Up | |

0.5625" ID | ||||||||||||||

| 3/4" | 3/4" | 9/16" | 1 3/64" | 1/4" | 3/4" | 0.0001" to 0.0005" | -0.0002" to 0" | -0.015" to 0.015" | SF | Steel | 00000000 | 000000 | 000000 | 000000 |

| 3/4" | 1" | 9/16" | 1 3/64" | 1/4" | 3/4" | 0.0001" to 0.0005" | -0.0002" to 0" | -0.015" to 0.015" | SF | Steel | 00000000 | 00000 | 00000 | 00000 |

| 1" | 3/4" | 9/16" | 1 27/64" | 3/8" | 59/64" | 0.0001" to 0.0005" | -0.0002" to 0" | -0.015" to 0.015" | SF | Steel | 00000000 | 00000 | 00000 | 00000 |

Shoulder | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bushing OD | Thread Size | Head OD | O'all Lg. | Head-to-Shoulder Lg. | Lg. | Wd. | Hex Size | For Drill Bushing Type | Material | Pkg. Qty. | Pkg. | |

Slotted | ||||||||||||

| 5/16", 1/2", 3/4" | 5/16"-18 | 5/8" | 5/8" | 1/4" | 0.138" | 3/8" | __ | SF | Steel | 10 | 0000000 | 000000 |

| 1", 1 3/8" | 5/16"-18 | 5/8" | 7/8" | 3/8" | 0.2" | 3/8" | __ | SF | Steel | 10 | 0000000 | 00000 |

Hex | ||||||||||||

| 5/16", 1/2", 3/4" | 5/16"-18 | 5/8" | 5/8" | 1/4" | 0.138" | 3/8" | 3/16" | SF | Steel | 10 | 0000000 | 00000 |

| 1", 1 3/8" | 5/16"-18 | 5/8" | 7/8" | 3/8" | 0.2" | 3/8" | 3/16" | SF | Steel | 10 | 0000000 | 00000 |

| For Bushing OD | ID | OD | Lg. | ID Tolerance | For Drill Bushing Type | Material | Hardness | Sleeve ANSI Number | Each | |

| 3/4" | 3/4" | 1" | 3/4" | 0.0003" to 0.0006" | SF | Steel | Rockwell C61 | L-64-12 | 00000000 | 000000 |

| 3/4" | 3/4" | 1" | 1" | 0.0003" to 0.0006" | SF | Steel | Rockwell C61 | L-64-16 | 00000000 | 00000 |

| 1" | 1" | 1 3/8" | 3/4" | 0.0004" to 0.0007" | SF | Steel | Rockwell C61 | L-88-12 | 00000000 | 00000 |

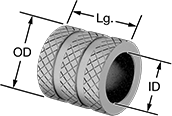

Secure-Hold Drill Bushings for Plastic

The knurls resist force and provide better holding strength than serrations. Encase in plastic tooling for precise drilling.

Also Available: Other sizes. Please select 3379A999 and specify ID, OD, and length.

For technical drawings and 3-D models, click on a part number.

Tolerance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Drill Bushing Type | Material | Hardness | Each | |

0.5625" ID | |||||||||

| 7/8" | 3/4" | 9/16" | 0.0001" to 0.0005" | 0.01" to 0.015" | DG | 1144 Carbon Steel | Rockwell C61 | 00000000 | 000000 |

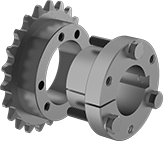

Quick-Disconnect (QD) Bushings

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect (QD) sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Wide-Rim Ring Shims

Also known as machinery bushings, these shims have an oversized OD to create a larger bearing surface for reduced wear between moving parts. Use them to precisely align, level, and adjust spacing on shafts and machinery.

Stainless steel shims are more corrosion resistant than carbon steel shims.

Carbon steel shims have excellent strength and can be welded.

A zinc-plated finish adds a layer of corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| ID | ID Tolerance | OD | OD Tolerance | Material | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

0.048" Thick. (-0.007" to 0.007" Tolerance) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | 18-8 Stainless Steel | Rockwell B38 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

0.075" Thick. (-0.007" to 0.007" Tolerance) | |||||||||

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | 18-8 Stainless Steel | Rockwell B38 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| ID | ID Tolerance | OD | OD Tolerance | Material | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

0.048" Thick. (-0.006" to 0.006" Tolerance) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | 1008-1010 Carbon Steel | Rockwell B38 | Magnetic | 25 | 000000000 | 00000 |

0.075" Thick. (-0.007" to 0.007" Tolerance) | |||||||||

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | 1008-1010 Carbon Steel | Rockwell B38 | Magnetic | 25 | 000000000 | 0000 |

| ID | ID Tolerance | OD | OD Tolerance | Material | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

0.048" Thick. (-0.006" to 0.006" Tolerance) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | Zinc-Plated 1008-1010 Carbon Steel | Rockwell B38 | Magnetic | 25 | 000000000 | 00000 |

0.075" Thick. (-0.007" to 0.007" Tolerance) | |||||||||

| 9/16" | 0.01" to 0.025" | 1" | -0.01" to 0.01" | Zinc-Plated 1008-1010 Carbon Steel | Rockwell B38 | Magnetic | 25 | 000000000 | 0000 |