About Plain Bearings

More

Multipurpose Flanged Sleeve Bearings

These bronze bearings are strong, wear resistant, and excellent at handling shock loads. They’re sometimes called 660 leaded bronze bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

For technical drawings and 3-D models, click on a part number.

| For Housing ID | Lg. | Flange OD | Flange Thick. | Dynamic Radial Load Capacity | Dynamic Thrust Load Capacity | Lubrication | Temperature Range, °F | Each | |

932 Bearing Bronze Bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For 1/16" Shaft Dia. | |||||||||

| 1/4" | 1/4" | 5/16" | 1/16" | 60 lbs. @ 120 rpm | 290 lbs. @ 120 rpm | Required | -350° to 450° | 00000000 | 000000 |

Press-Fit Drill Bushings

Mount flush with jig plates for precise drilling. These bushings can also be used as spacers, shims, and machinery bushings.

Don't see the size you need? Additional sizes are available.

For technical drawings and 3-D models, click on a part number.

Tolerance | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | 1-5 | 6-11 | 12-Up | |

0.0625" ID | ||||||||||||

| 5/32" | 1/4" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 000000 | 000000 | 000000 |

| 5/32" | 5/16" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 5/32" | 3/8" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 5/32" | 1/2" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 5/32" | 3/4" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 3/16" | 1/4" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 3/16" | 5/16" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 3/16" | 3/8" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 3/16" | 1/2" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 3/16" | 5/8" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 3/16" | 3/4" | 1/16" | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 13/64" | 1/4" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 13/64" | 5/16" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 13/64" | 3/8" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 0000 | 0000 |

| 13/64" | 1/2" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 13/64" | 3/4" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 13/64" | 1" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 13/64" | 1 3/8" | 1/16" | 0.0001" to 0.0004" | 0.0012" to 0.0015" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 0000 |

| 1/2" | 3/4" | 1/16" | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

Removable Drill Bushings

Replace worn bushings and quickly change IDs without needing to repeatedly use a lever press. Instead of pressing bushings in and out of your jig fixture, which can cause damage, these bushings slide in and out of sleeves (sold separately). By swapping in a bushing with a different ID, you can change the size of your bit and still use the same hole in your fixture. All are made to tight dimensional tolerances for consistent, accurate results, even as you change them in and out. They're also known as slip-fixed and renewable bushings.

Choose a sleeve with a length that matches the length of your bushing. To prevent bushings from spinning inside the sleeve as you drill, pair a standard sleeve with a lock screw, or use a locking sleeve.

Lock screws thread into a hole in your jig. The head of the screw fits into a notch on the bushing's head, which keeps the bushing from spinning.

For additional sizes, see Made-to-Order Removable Drill Bushings.

For technical drawings and 3-D models, click on a part number.

Head | Tolerance | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | OD | Thick. | Lock Screw/Bushing Ctr.-to-Ctr. | ID | OD | Lg. | Drill Bushing Type | Material | 1-5 | 6-11 | 12-Up | |

0.0625" ID | ||||||||||||||

| 5/16" | 3/4" | 1/16" | 35/64" | 1/4" | 1/2" | 0.0001" to 0.0004" | -0.0002" to 0" | -0.015" to 0.015" | SF | Steel | 00000000 | 000000 | 000000 | 000000 |

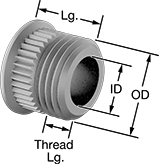

Removable Drill Bushings for Thin Metal

Unlike most bushings, these won’t buckle the material or distort the hole when installed in thin-gauge aluminum and steel plates. Insert them into a drilled hole and twist the lock ring to secure. Reusable and easy to replace, they are held in place by a lock ring (sold separately).

For technical drawings and 3-D models, click on a part number.

Tolerance | Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Lg. | For Drill Bit Size | ID | OD | For Material Thick. | Size | Lg. | Direction | Material | Hardness | Each | |

| 0.0625" | 3/8" | 1/2" | 1/16" | 0.0001" to 0.0015" | 0.003" to 0.005" | 1/64"-3/8" | 3/8"-24 | 1/4" | Left Hand | 1144 Carbon Steel | Rockwell C59 | 0000000 | 000000 |

| For Bushing OD | For Material Thick. | OD | Lg. | Material | Each | |

| 3/8" | 1/64"-1/8" | 1/2" | 3/8" | Aluminum | 0000000 | 00000 |

Tight-Fit Ring Shims

For a snug fit around a shaft, the ID of these shims is held to a tighter tolerance than other ring shims.

For accurate leveling, choose materials such as steel or stainless steel, which are hard enough to resist scratching and deforming. Softer shims, like brass, can be used as wear plates between components that rub together, preventing damage to equipment.

Stainless steel shims are more corrosion resistant than alloy steel shims.

For technical drawings and 3-D models, click on a part number.

| ID | ID Tolerance | OD | OD Tolerance | Material | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

0.001" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 000000 |

0.002" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.003" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.004" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.005" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.006" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.008" Thick. (-0.0005" to 0.0005" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.01" Thick. (-0.001" to 0.001" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.012" Thick. (-0.001" to 0.001" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.014" Thick. (-0.001" to 0.003" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |

0.016" Thick. (-0.002" to 0.002" Tolerance) | |||||||||

| 1/16" | 0" to 0.005" | 5/32" | -0.005" to 0.005" | 18-8 Stainless Steel | Rockwell B70 | May Be Mildly Magnetic | 25 | 000000000 | 00000 |