Filter by

Thread Size

Material

Thread Type

Thread Spacing

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

RoHS

REACH

For Lock Washer Specifications Met

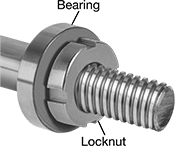

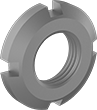

Bearing Locknuts

|

|  |

Carbon Steel | Zinc-Plated Carbon Steel |

| |

303 Stainless Steel |

With a nylon insert that grips your threaded shaft or spindle without damaging its threads, these locknuts—also called shaft nuts—hold bearings, bushings, gears, and pulleys prone to vibration tightly in place. They come as one piece, so you can easily clamp them onto your shaft or spindle. But, since they aren’t made entirely of metal, they don’t stand up to heat as well as all-metal locknuts. Slots in their sides mean you can tighten and loosen them with a spanner wrench or spanner socket. Their face is also chamfered to help keep the size and weight of your assembly at a minimum. All meet international standards for bearing locknut dimensions.

Zinc-Plated Carbon Steel—Zinc-plated carbon steel locknuts resist rusting from some moisture, but you shouldn’t use them with salt water or chemicals. They are strong and resist wear, though they don’t stand up to corrosion as well as 303 stainless steel locknuts.

Carbon Steel—All carbon steel locknuts are strong and resist wear, though they don’t stand up to corrosion as well as 303 stainless steel locknuts.

303 Stainless Steel—303 stainless steel locknuts resist corrosion better than carbon steel locknuts but aren’t as strong. They withstand washdowns and chemicals.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Locknuts | Sockets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Carbon Steel | Zinc-Plated Carbon Steel | 303 Stainless Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Spacing | OD | Wd. | Insert Max. Temp., ° F | Specs. Met | Each | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.391"-32 | Extra Fine | 3/4" | 9/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.469"-32 | Extra Fine | 7/8" | 3/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 0000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.586"-32 | Extra Fine | 1" | 3/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 0000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.664"-32 | Extra Fine | 1 1/8" | 13/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 0000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.781"-32 | Extra Fine | 1 3/8" | 13/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.969"-32 | Extra Fine | 1 9/16" | 15/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.173"-18 | Extra Fine | 1 3/4" | 15/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.312"-18 | Extra Fine | 2 1/16" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.376"-18 | Extra Fine | 2 1/16" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.563"-18 | Extra Fine | 2 1/4" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.767"-18 | Extra Fine | 2 17/32" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.967"-18 | Extra Fine | 2 11/16" | 9/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.157"-18 | Extra Fine | 2 31/32" | 9/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.360"-18 | Extra Fine | 3 5/32" | 19/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.548"-18 | Extra Fine | 3 3/8" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.751"-18 | Extra Fine | 3 5/8" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 21/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.137"-12 | Extra Fine | 4 5/32" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | ——— | 0 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.340"-12 | Extra Fine | 4 13/32" | 23/32" | 160 | ANSI/ABMA 8.2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.527"-12 | Extra Fine | 4 21/32" | 25/32" | 160 | ANSI/ABMA 8.2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.730"-12 | Extra Fine | 4 15/16" | 13/16" | 160 | ANSI/ABMA 8.2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.918"-12 | Extra Fine | 5 3/16" | 13/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | ——— | 0 | 0000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.325"-12 | Extra Fine | 5 23/32" | 15/16" | 160 | ANSI/ABMA 8.2 | 00000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.716"-12 | Extra Fine | 6 1/8" | 15/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 0.75 mm | Extra Fine | 18 mm | 7 mm | 160 | ISO 2982-2 | 0000000 | 0000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 0.75 mm | Extra Fine | 18 mm | 7.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1 mm | Extra Fine | 18 mm | 7.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | Coarse | 18 mm | 7.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1 mm | Extra Fine | 21 mm | 7.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1 mm | Extra Fine | 22 mm | 8 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.5 mm | Fine | 21 mm | 9 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 1 mm | Extra Fine | 24 mm | 8.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 1.5 mm | Fine | 24 mm | 10.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M15 × 1 mm | Extra Fine | 24 mm | 8.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M15 × 1 mm | Extra Fine | 25 mm | 8.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 1 mm | Extra Fine | 28 mm | 8.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 1.5 mm | Fine | 28 mm | 10.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M17 × 1 mm | Extra Fine | 28 mm | 8.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M17 × 1 mm | Extra Fine | 28 mm | 9 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1 mm | Extra Fine | 28 mm | 8.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1.5 mm | Fine | 28 mm | 10.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1 mm | Extra Fine | 32 mm | 9.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1 mm | Extra Fine | 32 mm | 10 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1.5 mm | Extra Fine | 32 mm | 9.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1 mm | Extra Fine | 34 mm | 10.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1 mm | Extra Fine | 38 mm | 10 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | Fine | 38 mm | 12.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 1.5 mm | Extra Fine | 38 mm | 10.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M25 × 1.5 mm | Extra Fine | 38 mm | 10.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M25 × 1.5 mm | Extra Fine | 38 mm | 11 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M27 × 1.5 mm | Extra Fine | 44 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 1.5 mm | Extra Fine | 42 mm | 11 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 1.5 mm | Extra Fine | 44 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 44 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 45 mm | 11.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 × 1.5 mm | Extra Fine | 48 mm | 11.5 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 × 1.5 mm | Extra Fine | 50 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M34 × 1.5 mm | Extra Fine | 50 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 50 mm | 11 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 52 mm | 12 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M38 × 1.5 mm | Extra Fine | 53 mm | 11.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 56 mm | 12 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 58 mm | 12 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | Extra Fine | 62 mm | 15 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 62 mm | 12 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 65 mm | 13 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M48 × 1.5 mm | Extra Fine | 64 mm | 13.5 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 68 mm | 13 mm | 210 | — | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 70 mm | 13 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M52 × 1.5 mm | Extra Fine | 75 mm | 13.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 2 mm | Extra Fine | 75 mm | 13.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 2 mm | Extra Fine | 75 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 2 mm | Extra Fine | 80 mm | 13.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 2 mm | Extra Fine | 80 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 2 mm | Extra Fine | 85 mm | 14.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 2 mm | Extra Fine | 85 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 × 2 mm | Extra Fine | 92 mm | 14.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 × 2 mm | Extra Fine | 92 mm | 17 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M75 × 2 mm | Extra Fine | 98 mm | 15.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M75 × 2 mm | Extra Fine | 98 mm | 17 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M80 × 2 mm | Extra Fine | 105 mm | 16.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M80 × 2 mm | Extra Fine | 105 mm | 17 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M85 × 2 mm | Extra Fine | 110 mm | 17.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M85 × 2 mm | Extra Fine | 110 mm | 18 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | ——— | 0 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M90 × 2 mm | Extra Fine | 120 mm | 17.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M95 × 2 mm | Extra Fine | 125 mm | 18.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M95 × 2 mm | Extra Fine | 125 mm | 20 mm | 160 | ISO 2982-2 | 00000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M100 × 2 mm | Extra Fine | 130 mm | 19.5 mm | 210 | — | ——— | 0 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M100 × 2 mm | Extra Fine | 130 mm | 21 mm | 160 | ISO 2982-2 | 00000000 | 000000 | ——— | 0 | ——— | 0 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M120 × 2 mm | Extra Fine | 155 mm | 23 mm | 160 | ISO 2982-2 | 00000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

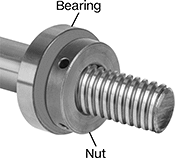

Bearing Nuts

Often paired with spring lock washers to strengthen their hold, these bearing nuts—also known as shaft nuts—keep vibration from shifting bearings, bushings, pulleys, and gears on your threaded shaft or spindle. They have slotted sides, so you can tighten and loosen them with a spanner wrench or spanner socket.

Carbon Steel—Carbon steel bearing nuts are strong and resist wear.

303 Stainless Steel—303 stainless steel bearing nuts resist corrosion better than carbon steel. They also withstand washdowns and chemicals.

Chamfered Face—Chamfered-face bearing nuts weigh less and produce less heat than stepped-face nuts.

Stepped Face—Use stepped-face bearing nuts with DIN 462 spring lock washers. You can also use them in pairs or with other bearing nuts. For the nut closer to the bearing, position the stepped face towards the bearing. All meet DIN standards for bearing lockout dimensions.

ISO 2982— Some chamfered-face bearing nuts meet ISO 2982 (formerly DIN 981), an international standard for bearing locknut dimensions. Their sizes correspond to SKF KM series. Use them with DIN 5406 spring lock washers.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Nuts | Bearing Lock Washers | Sockets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Spacing | OD | Wd. | Specs. Met | For Lock Washer Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.391"-32 | Extra Fine | 3/4" | 7/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 00000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.469"-32 | Extra Fine | 7/8" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.586"-32 | Extra Fine | 1" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.664"-32 | Extra Fine | 1 1/8" | 11/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.781"-32 | Extra Fine | 1 3/8" | 3/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.969"-32 | Extra Fine | 1 9/16" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.173"-18 | Extra Fine | 1 3/4" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.312"-18 | Extra Fine | 2 1/16" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.376"-18 | Extra Fine | 2 1/16" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.563"-18 | Extra Fine | 2 1/4" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.767"-18 | Extra Fine | 2 17/32" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.967"-18 | Extra Fine | 2 11/16" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.157"-18 | Extra Fine | 2 31/32" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.360"-18 | Extra Fine | 3 5/32" | 17/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.548"-18 | Extra Fine | 3 3/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.751"-18 | Extra Fine | 3 5/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.137"-12 | Extra Fine | 4 5/32" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.340"-12 | Extra Fine | 4 13/32" | 5/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.527"-12 | Extra Fine | 4 21/32" | 11/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.730"-12 | Extra Fine | 4 15/16" | 23/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 00000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.918"-12 | Extra Fine | 5 3/16" | 3/4" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 00000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.325"-12 | Extra Fine | 5 23/32" | 25/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.716"-12 | Extra Fine | 6 1/8" | 13/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 00000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 0.75 mm | Extra Fine | 18 mm | 4 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1 mm | Extra Fine | 22 mm | 4 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M15 × 1 mm | Extra Fine | 25 mm | 5 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M17 × 1 mm | Extra Fine | 28 mm | 5 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1 mm | Extra Fine | 32 mm | 6 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M25 × 1.5 mm | Extra Fine | 38 mm | 7 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 45 mm | 7 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 52 mm | 8 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 58 mm | 9 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 0000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 65 mm | 10 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 70 mm | 11 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 2 mm | Extra Fine | 75 mm | 11 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 2 mm | Extra Fine | 80 mm | 11 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 2 mm | Extra Fine | 85 mm | 12 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 × 2 mm | Extra Fine | 92 mm | 12 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M75 × 2 mm | Extra Fine | 98 mm | 13 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M80 × 2 mm | Extra Fine | 105 mm | 15 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M85 × 2 mm | Extra Fine | 110 mm | 16 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M90 × 2 mm | Extra Fine | 120 mm | 16 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M95 × 2 mm | Extra Fine | 125 mm | 17 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M100 × 2 mm | Extra Fine | 130 mm | 18 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M105 × 2 mm | Extra Fine | 140 mm | 18 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M110 × 2 mm | Extra Fine | 145 mm | 19 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M115 × 2 mm | Extra Fine | 150 mm | 19 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M120 × 2 mm | Extra Fine | 155 mm | 20 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M125 × 2 mm | Extra Fine | 160 mm | 21 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M130 × 2 mm | Extra Fine | 165 mm | 21 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 00000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M135 × 2 mm | Extra Fine | 175 mm | 22 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M140 × 2 mm | Extra Fine | 180 mm | 22 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M145 × 2 mm | Extra Fine | 190 mm | 24 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M150 × 2 mm | Extra Fine | 195 mm | 24 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M155 × 3 mm | Extra Fine | 200 mm | 25 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M160 × 3 mm | Extra Fine | 210 mm | 25 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M165 × 3 mm | Extra Fine | 210 mm | 26 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M170 × 3 mm | Extra Fine | 220 mm | 26 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M180 × 3 mm | Extra Fine | 230 mm | 27 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M190 × 3 mm | Extra Fine | 240 mm | 28 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M200 × 3 mm | Extra Fine | 250 mm | 29 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M220 × 4 mm | Extra Fine | 280 mm | 32 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M240 × 4 mm | Extra Fine | 300 mm | 34 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M260 × 4 mm | Extra Fine | 330 mm | 36 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M280 × 4 mm | Extra Fine | 350 mm | 38 mm | DIN 981, ISO 2982 | DIN 5406 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepped Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1 mm | Fine | 20 mm | 5 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.5 mm | Fine | 28 mm | 6 mm | DIN 1804 | DIN 462 | 0000000 | 0000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 1.5 mm | Fine | 30 mm | 7 mm | DIN 1804 | DIN 462 | 0000000 | 0000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 1.5 mm | Fine | 32 mm | 7 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1.5 mm | Fine | 34 mm | 8 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1.5 mm | Extra Fine | 36 mm | 8 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 1.5 mm | Extra Fine | 42 mm | 9 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M26 × 1.5 mm | Extra Fine | 45 mm | 10 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 1.5 mm | Extra Fine | 50 mm | 10 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 50 mm | 10 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 × 1.5 mm | Extra Fine | 52 mm | 11 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 55 mm | 11 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M38 × 1.5 mm | Extra Fine | 58 mm | 11 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 62 mm | 12 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | Extra Fine | 62 mm | 12 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 68 mm | 12 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 75 mm | 13 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | 000000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 1.5 mm | Extra Fine | 80 mm | 13 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 1.5 mm | Extra Fine | 90 mm | 13 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 1.5 mm | Extra Fine | 95 mm | 14 mm | DIN 1804 | DIN 462 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.391"-32 | Extra Fine | 3/4" | 7/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.469"-32 | Extra Fine | 7/8" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.586"-32 | Extra Fine | 1" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.664"-32 | Extra Fine | 1 1/8" | 11/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.781"-32 | Extra Fine | 1 3/8" | 3/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.969"-32 | Extra Fine | 1 9/16" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.173"-18 | Extra Fine | 1 3/4" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.376"-18 | Extra Fine | 2 1/16" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.563"-18 | Extra Fine | 2 1/4" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.767"-18 | Extra Fine | 2 17/32" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.967"-18 | Extra Fine | 2 11/16" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.157"-18 | Extra Fine | 2 31/32" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.360"-18 | Extra Fine | 3 5/32" | 17/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.548"-18 | Extra Fine | 3 3/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.751"-18 | Extra Fine | 3 5/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.137"-12 | Extra Fine | 4 5/32" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.340"-12 | Extra Fine | 4 13/32" | 5/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.527"-12 | Extra Fine | 4 21/32" | 11/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.730"-12 | Extra Fine | 4 15/16" | 23/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.918"-12 | Extra Fine | 5 3/16" | 3/4" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.325"-12 | Extra Fine | 5 23/32" | 25/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.716"-12 | Extra Fine | 6 1/8" | 13/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

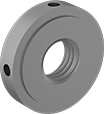

Thin-Profile Bearing Nuts

|

|

Used in pairs or with another bearing nut, these thin-profile nuts—often called shaft nuts—hold bearings, bushings, pulleys, and gears in place on your threaded shaft or spindle. Threading two nuts tightly against each other makes it harder for vibration to loosen your assembly than if you used only one nut. For the nut closer to the bearing, position the stepped face towards the bearing. These thin-profile nuts have holes on the side, so you can tighten and loosen them with a pin spanner wrench. All meet DIN 1816, an international standard for bearing locknut dimensions.

Carbon Steel—Carbon steel bearing nuts are strong and resist wear.

Thread Spacing—When choosing your thread spacing, consider the precision of your application. The finer the threads, the more control you have when making adjustments.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Spacing | OD, mm | Wd., mm | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stepped Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1 mm | Fine | 20 | 5 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.5 mm | Fine | 28 | 6 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 1.5 mm | Fine | 30 | 7 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 1.5 mm | Fine | 32 | 7 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1.5 mm | Fine | 34 | 8 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1.5 mm | Extra Fine | 36 | 8 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1.5 mm | Fine | 40 | 9 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 1.5 mm | Extra Fine | 42 | 9 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M26 × 1.5 mm | Extra Fine | 45 | 10 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 1.5 mm | Extra Fine | 50 | 10 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 50 | 10 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 55 | 11 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 62 | 12 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 × 1.5 mm | Extra Fine | 62 | 12 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 68 | 12 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M48 × 1.5 mm | Extra Fine | 75 | 13 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 75 | 13 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M52 × 1.5 mm | Extra Fine | 80 | 13 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 1.5 mm | Extra Fine | 80 | 13 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 1.5 mm | Extra Fine | 90 | 13 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M62 × 1.5 mm | Extra Fine | 95 | 14 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 1.5 mm | Extra Fine | 95 | 14 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M68 × 1.5 mm | Extra Fine | 100 | 14 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 × 1.5 mm | Extra Fine | 100 | 14 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M72 × 1.5 mm | Extra Fine | 110 | 14 | DIN 1816 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M75 × 1.5 mm | Extra Fine | 110 | 14 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M80 × 2 mm | Extra Fine | 115 | 16 | DIN 1816 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||