Steel Drum Head Cutters

Remove the top from a steel drum leaving a clean edge and lip. The drum can then be used with Steel Drum Covers. Also known as drum deheaders, these cutters are for occasional use. Turn the knob to clamp the cutter onto a drum, then push down and pull up on the handle to cut around the head.

Copper is nonsparking for use with flammable materials.

Electric Steel Drum Head Cutters

For intermittent use, these drum head cutters can remove the heads from up to 10 drums per day. A quiet motor propels a round blade leaving a clean edge. The drum is then ready for use with steel drum covers. These cutters are also known as drum deheaders.

Drum Capacity, gal. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | For Max. Drum Lip Thick., ga. | Blade Material | Material | Ht. | Wd. | Dp. | Power, hp | Voltage | Cord Lg. | Plug Type | Each | |

| 30 | 55 | 16 | Steel | Aluminum, Steel | 24" | 10" | 12" | 1/8 | 115V AC | 31 1/2" | Three Prong | 00000000 | 000000000 |

Heavy Duty Electric Steel Drum Head Cutters

Choose these cutters for continuous use. A quiet motor propels a round blade leaving a clean edge. The drum is then ready for use with Steel Drum Covers. These cutters are also known as drum deheaders.

Drum Capacity, gal. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | For Max. Drum Lip Thick., ga. | Blade Material | Material | Ht. | Wd. | Dp. | Power, hp | Voltage | Cord Lg. | Plug Type | Each | |

| 30 | 55 | 16 | Steel | Aluminum, Steel | 25" | 11" | 17" | 1/3 | 110V AC | 31 1/2" | Three Prong | 0000000 | 000000000 |

Air-Powered Steel Drum Head Cutters

Make fast cuts without manual effort. Unlike Electric Steel Drum Head Cutters, this is for use in areas where work surfaces are wet. Nonmarring rollers guide the cutter around the head leaving a clean edge and lip for use with steel drum covers. This cutter is for continuous use. It's also known as a drum deheader.

Drum Capacity, gal. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | For Max. Drum Lip Thick., ga. | Blade Material | Material | Ht. | Wd. | Dp. | Air Pressure, psi | Air Consumption, cfm | For Air Hose ID | Air Hose Included | Thread Type | Pipe Size | Gender | Each | |

| 30 | 55 | 16 | Steel | Aluminum, Steel | 25" | 11" | 17" | 60-100 | 25 | 1/2" | No | NPT | 1/4 | Male | 0000000 | 000000000 |

Easy-Cut Steel Drum Head Cutters

This cutter uses ratchet action to provide more force with less effort. Also known as a drum deheader, it leaves a clean edge and lip for use with steel drum covers. Clamp the cutter onto your drum lip, then move the handle up and down to cut.

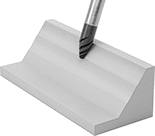

Fast-Cutting Carbide Barrel End Mills for Aluminum, Brass, and Bronze

Barrel Cut Style | 3 Flute |

4 Flute |

A titanium-diboride (TiB2) coating reduces friction when working with nonferrous metals, so you can use these end mills to cut soft metals like aluminum, brass, and bronze. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. Also known as barrel cutters, these end mills create the smooth finish of a ball end mill, but with a tapered cutting surface that removes more material with each pass. They're ideal for 5-axis machining where you need to cut from many angles. Plus, compared to ball end mills, they move farther between overlapping passes (stepover), which decreases machining time and tool wear, so they’ll last longer. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

End mills with three flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Max. Taper Dia., mm | Shank Dia., mm | Lg. of Cut , mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Diboride (TiB2) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

3 Flute | ||||||||||

| 1 | 3 | 6 | 9 | 58 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 0000000 |

| 1.5 | 3 | 6 | 8 | 58 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 1.5 | 4 | 8 | 10 | 80 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 4 | 8 | 9 | 80 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 5 | 10 | 12 | 89 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2.5 | 5 | 10 | 11 | 89 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

4 Flute | ||||||||||

| 2 | 3 | 16 | 15 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 5 | 16 | 31 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 6 | 12 | 20 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2.5 | 6 | 12 | 14 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 18 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 19 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 27 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 6 | 12 | 13 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 21 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 24 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 28 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 8 | 16 | 18 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

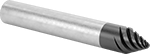

Fast-Cutting Carbide Barrel End Mills

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. Also known as barrel cutters, these end mills create the smooth finish of a ball end mill, but with a tapered cutting surface that removes more material with each pass. They're ideal for 5-axis machining where you need to cut from many angles. Plus, compared to ball end mills, they move farther between overlapping passes (stepover), which decreases machining time and tool wear, so they’ll last longer. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Max. Taper Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||||

| 1 | 3 | 6 | 9.5 | 58 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

| 1.5 | 3 | 6 | 8 | 58 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1.5 | 4 | 8 | 10.5 | 80 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 4 | 8 | 9.5 | 80 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

6 Flute | ||||||||||

| 2 | 3 | 16 | 15 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 5 | 10 | 12.5 | 89 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 5 | 16 | 31 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2 | 6 | 12 | 20 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 2.5 | 5 | 10 | 11.5 | 89 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

8 Flute | ||||||||||

| 2.5 | 6 | 12 | 14.4 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 5 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 5 | 16 | 27.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 6 | 12 | 13.5 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 21 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 24 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 28.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 8 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |