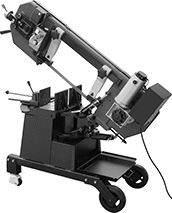

Adjustable Band Saws for Metal

Highly versatile, these saws make precise horizontal and vertical cuts from a single saw. They work well whether you’re simply cutting metal into smaller pieces or creating complex shapes. When the blade is horizontal, these saws cut from above, making square or angled cuts. For straight or intricate curved cuts, position the blade vertically and feed your workpiece through. They’re powerful enough to cut through aluminum, steel, and stainless steel. However, they should only be used for dry cutting.

The higher the horsepower, the smoother the cut, even in thick and hard metals.

Direct-drive saws send power straight to the blade instead of a belt, which keeps power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Max. Cutting | Blade | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Drive Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | No. of Wheels | Each | |

Manual Feed System | |||||||||||||||||

| 5 A @ 120 V AC | 1 1/4 | Direct | 10" | 8" | 10" | 45° (Left/Right) | 65-250 | 118" | 1" | 0.035" | 60" | 24" | 50" | 560 | 4 | 00000000 | 000000000 |

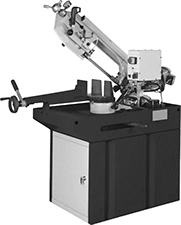

Horizontal Band Saws for Metal

Make repeat cuts in pipes, bars, and thick metal sheets. These saws make more precise straight and angled cuts than vertical band saws by cutting from above into a clamped workpiece. For smooth cuts every time, the saw head uses hydraulics to move at a controlled speed. Once the blade reaches your material, the weight of the saw head completes the cut for you. The built-in coolant system prevents overheating, so the blade lasts longer and your workpiece won’t harden or warp. The coolant also keeps the cut area clear of metal shards to stop them from sticking onto the blade.

Direct-drive saws send power straight to the blade instead of a belt, which keeps the power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Saws with cutting resistance detection automatically adjust their speed to protect the blade from bending and the teeth from chipping. The blade slows down for hard materials and speeds up for soft ones. Since you don’t need any tools to access the blade, swapping it out is quick and easy.

Saws with blade tension detection prevent startup if the blade is loose, misaligned, or broken. As a fail-safe, they can also stop mid-cut.

Max. Cutting | Blade | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Feed System Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | No. of Wheels | Features | Each | |

Direct Drive | ||||||||||||||

Single Phase—Three-Prong Plug | ||||||||||||||

| 13 A @ 120 V AC | 1 1/2 | Automatic, Manual | 9" | 16" | 9" | 45° (Left) 60° (Right) | 98-262 | 131 1/2" | 1" | 0.035" | 0 | Cutting Resistance Detection Front Blade Access Quick-Release Vise Removable Chip Tray Removable Coolant Tank | 0000000 | 000000000 |

Three Phase—Three-Prong Plug | ||||||||||||||

| 9 A @ 120 V AC | 1 1/2 | Automatic | 8 5/8" | 9" | 8 5/8" | 60° (Left/Right) | 115-230 | 97" | 1" | 0.035" | 0 | Blade Tension Detection Quick-Release Vise | 0000000 | 00000000 |