About Carbon Steel, Alloy Steel, Spring Steel, and Cast Iron

More

About Plastic

More

About Aluminum

More

About Rubber

More

Tight-Tolerance Multipurpose 304 Stainless Steel

This material has tighter tolerances than standard 304 stainless steel. From cookware to chemical-processing equipment, 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

Balls have a reflective, mirror-like finish.

Steel that meets ASTM or SAE specifications complies with standards for materials.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: Not Rated

- Hardness: Rockwell C25 (Hard)

- Heat Treatable: No

| Dia. | Dia. Tolerance | Fabrication | Specifications Met | Pkg. Qty. | Pkg. | |

Mirror-Like | ||||||

|---|---|---|---|---|---|---|

| 1 3/4" | -0.001" to 0.001" | Cold Worked | ASTM A240, ISO 3290, SAE J405 | 1 | 0000000 | 000000 |

Hard Wear-Resistant 52100 Alloy Steel Balls

- Yield Strength: 295,000 psi

- Hardness: Rockwell C60 (Very Hard)

- Specifications Met: See table

Also known as chrome steel, 52100 is an extremely hard and wear-resistant material. These balls are often used in bearings.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Heat Treatment | Pkg. Qty. | Pkg. | |

Mirror-Like | |||||

|---|---|---|---|---|---|

| 1 3/4" | -0.0002" to 0.0002" | Hardened | 1 | 0000000 | 000000 |

Aluminum Balls

Lighter in weight than steel and stronger than plastic, these aluminum balls are widely used in bearings and in valves.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Material | Yield Strength | Temper | Hardness | Heat Treatment | Pkg. Qty. | Pkg. | |

| 1 3/4" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 0000000 |

Wear-Resistant Nylon Balls

- Color: Off-White

- Temperature Range: Not Rated

- Tensile Strength: 11,200-12,300 psi (Good)

- Impact Strength: 0.6-1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R108-R121 (Hard)

- For Use Outdoors: No

Use these nylon 6/6 balls as bearings and in sealing applications. They have a slippery surface that reduces wear caused by friction.

For technical drawings and 3-D models, click on a part number.

| Dia. | Dia. Tolerance | Pkg. Qty. | Pkg. | |

Inch | ||||

|---|---|---|---|---|

| 1 3/4 " | -0.002" to 0.002" | 1 | 0000000 | 000000 |

Chemical-Resistant Slippery PTFE Balls

- Color: White

- Max. Temperature: 500° F

- Tensile Strength: See Table (Poor)

- Impact Strength: 3.5 ft.-lbs./in. (Good)

- Hardness: Durometer 50D-65D (Medium Soft)

- For Use Outdoors: Yes

Offering a nonstick, slippery surface, these PTFE balls are often used as bearings and in ball valves. They offer superior chemical resistance and perform well in extreme temperatures. These balls are also excellent electrical insulators.

For technical drawings and 3-D models, click on a part number.

| Dia. | Dia. Tolerance | Tensile Strength | Pkg.Qty. | Pkg. | |

| 1 3/4" | -0.005" to 0.005" | 3,000-5,000 psi | 1 | 0000000 | 000000 |

Abrasion-Resistant Polyurethane Rubber Balls

Use these polyurethane balls as seals in pumps and check valves or let them bounce inside of vibrating sifters for an effective screen cleaner. They are made of polyurethane, which combines the shock absorbing qualities of rubber with the strength of plastic.

For technical drawings and 3-D models, click on a part number.

- Color: Black

- Temperature Range: -20° to 200° F

- Tensile Strength: 5,600 psi

- For Use Outdoors: Yes

| Dia. | Dia. Tolerance | Durometer | Each | |

| 1 3/4" | -0.020" to +0.020" | 95A (Extra Hard) | 0000000 | 000000 |

Stud-Mount Ball Transfers

Install these ball transfers in a threaded hole or use a nut to secure.

Steel balls are durable. Stainless steel balls offer the most corrosion resistance. Nylon and polypropylene balls are nonmarking. Nylon is stronger than polypropylene. However, polypropylene resists chemicals better than nylon.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Thread Size | Stud Lg. | Temperature Range, °F | Each | ||

Steel Ball | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel Housing | ||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 1/4"-20 | 11/16" | __ | 0000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 11/16" | __ | 00000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 5/16"-18 | 11/16" | __ | 0000000 | 0000 |

Stainless Steel Ball | ||||||||||

Zinc-Plated Steel Housing | ||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 5/16"-18 | 11/16" | __ | 0000000 | 00000 |

Stainless Steel Housing | ||||||||||

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 1/4"-20 | 11/16" | __ | 0000000 | 00000 |

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 11/16" | __ | 00000000 | 00000 |

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 5/16"-18 | 11/16" | __ | 0000000 | 00000 |

Nylon Plastic Ball | ||||||||||

Zinc-Plated Steel Housing | ||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 1/4"-20 | 11/16" | 32° to 212° | 0000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 11/16" | Not Rated to 125° | 00000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 5/16"-18 | 11/16" | 32° to 212° | 0000000 | 00000 |

Stainless Steel Housing | ||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 1/4"-20 | 11/16" | 32° to 212° | 0000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 11/16" | Not Rated to 125° | 00000000 | 00000 |

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | 5/16"-18 | 11/16" | 32° to 212° | 0000000 | 00000 |

Heavy Duty Stud-Mount Ball Transfers

Steel balls are durable.

Stainless steel balls resist corrosion the best.

Nylon balls are nonmarking.

Ball transfers with an angled working orientation can be used to form support stands.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Thread Size | Stud Lg. | Each | ||

Steel Ball | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel Housing | |||||||||

| B | 1 3/16" | 700 | 1 7/16" | 1 3/4" | Ball Up, Ball Down, Angle | 3/8"-16 | 1" | 00000000 | 000000 |

| C | 1 3/16" | 700 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 00000000 | 00000 |

Black-Oxide Steel Housing | |||||||||

| A | 1" | 500 | 1 7/8" | 1 3/4" | Ball Up, Ball Down, Angle | 1/2"-20 | 1" | 0000000 | 000000 |

Stainless Steel Ball | |||||||||

Zinc-Plated Steel Housing | |||||||||

| B | 1 3/16" | 700 | 1 7/16" | 1 3/4" | Ball Up, Ball Down, Angle | 3/8"-16 | 1" | 0000000 | 000000 |

Stainless Steel Housing | |||||||||

| B | 1 3/16" | 700 | 1 7/16" | 1 3/4" | Ball Up, Ball Down, Angle | 3/8"-16 | 1" | 0000000 | 000000 |

| C | 1 3/16" | 900 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 0000000 | 000000 |

Nylon Plastic Ball | |||||||||

Zinc-Plated Steel Housing | |||||||||

| C | 1 3/16" | 700 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 0000000 | 00000 |

Stainless Steel Housing | |||||||||

| C | 1 3/16" | 700 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 0000000 | 000000 |

Flange-Mount Ball Transfers

Steel balls are durable.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Lg. | Wd. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Each | ||

Steel Ball | ||||||||||||

Zinc-Plated Steel Housing | ||||||||||||

| B | 1" | 120 | 1 3/16" | 1 3/4" | Ball Up, Ball Down | 2 11/16" | 2" | 2 | 3/16" | 2 3/8" | 00000000 | 000000 |

Heavy Duty Flange-Mount Ball Transfers

A steel ball in these ball transfers makes them durable. Orient them at an angle to form support stands.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Lg. | Wd. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Each | ||

Steel Ball | ||||||||||||

Black-Oxide Steel Housing | ||||||||||||

| B | 1" | 500 | 1 5/8" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/4" | 2 1/4" | 4 | 7/32" | 1 3/4" | 0000000 | 0000000 |

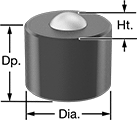

Heavy Duty Press-Fit Ball Transfers

Drop-in design makes for easy installation. When used at an angled working orientation, these ball transfers can be used to form support stands.

Steel balls are durable.

Capacity is given in ball up orientation. Ball down or angled could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

| Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Each | ||

Steel Ball | ||||||||

|---|---|---|---|---|---|---|---|---|

Black-Oxide Steel Housing | ||||||||

| A | 1" | 500 | 9/32" | 1 11/32" | 1 3/4" | Ball Up, Ball Down, Angle | 0000000 | 0000000 |

Recessed Flange-Mount Ball Transfers

Transfers recess into the mounting surface for a low profile. These ball transfers can be used in an angled working orientation to form support stands.

Steel balls are durable. Stainless steel balls offer the most corrosion resistance. They don’t need to be lubricated. Nylon balls are nonmarking.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Lg. | Wd. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Temperature Range, °F | Each | ||

Steel Ball | ||||||||||||||

Zinc-Plated Steel Housing | ||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

Nylon Plastic Ball | ||||||||||||||

Zinc-Plated Steel Housing | ||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | 2 | 7/32" | 2 3/16" | 32° to 195° | 0000000 | 00000 |

Stainless Steel Ball | ||||||||||||||

Zinc-Plated Steel Housing | ||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

Stainless Steel Housing | ||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

Heavy Duty Recessed Flange-Mount Ball Transfers

These ball transfers recess into the mounting surface for a low profile. Position them at an angle to form support stands. They are made of steel, so they are durable.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Lg. | Wd. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Each | |

Steel Ball with Top Flange | |||||||||||||

Black-Oxide Steel Housing | |||||||||||||

| B | 1" | 500 | 15/32" | 1 5/32" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/4" | 2 1/4" | 4 | 7/32" | 1 3/4" | 0000000 | 0000000 |

Wood Balls

For technical drawings and 3-D models, click on a part number.

| Dia. | Dia. Tolerance | Pkg. Qty. | Pkg. | |

Birch | ||||

|---|---|---|---|---|

| 1 3/4" | -0.031" to 0.031" | 10 | 0000000 | 000000 |