Selecting Compatible Lead Screws and Nuts

More

About Set Screws

More

Ball Screws and Nuts

Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. Also known as single-start ball screws and nuts, they have a single thread that runs the length of the screw. They operate with more torque than fast-travel ball screws and nuts. To ensure compatibility, select components that have the same thread direction and size. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

For technical drawings and 3-D models, click on a part number.

Root diameter indicates the diameter the ball screw will be after machining away the threads.

Ball Screw | Flange Ball Nut | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg., mm | Root Dia., mm | Tensile Strength, psi | Lg., mm | Dia., mm | Length Tolerance | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Dynamic Thrust Load Capacity, lbs. | Max. Backlash, mm | Temp. Range, °F | Each | |

Carbon Steel Ball Screw with Alloy Steel Flange Ball Nut | |||||||||||||||

| M6 | 150 | 5.3 | 21,000 | 21 | 13 | Plus | 1 | 1 | ±0.210 mm per 300 mm | Rockwell C58 | 150 | 0.05 | 5° to 175° | 0000000 | 0000000 |

| M6 | 250 | 5.3 | 21,000 | 21 | 13 | Plus | 1 | 1 | ±0.210 mm per 300 mm | Rockwell C58 | 150 | 0.05 | 5° to 175° | 000000 | 000000 |

| M8 | 150 | 6.6 | 21,000 | 28 | 20 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 470 | 0.05 | 5° to 175° | 0000000 | 000000 |

| M8 | 250 | 6.6 | 21,000 | 28 | 20 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 470 | 0.05 | 5° to 175° | 000000 | 000000 |

| M10 | 200 | 8.6 | 21,000 | 28 | 23 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 510 | 0.05 | 5° to 175° | 0000000 | 000000 |

| M10 | 300 | 8.6 | 21,000 | 28 | 23 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 510 | 0.05 | 5° to 175° | 000000 | 000000 |

| M12 | 200 | 10.6 | 21,000 | 30 | 25 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 560 | 0.05 | 5° to 175° | 000000 | 000000 |

| M12 | 300 | 10.6 | 21,000 | 30 | 25 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 560 | 0.05 | 5° to 175° | 0000000 | 000000 |

Root diameter indicates the diameter the ball screw will be after machining away the threads.

| Thread Size | Lg. | No. of Thread Starts | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Root Dia. | Hardness | Tensile Strength, psi | Temp. Range, °F | Each | |

Carbon Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M14 | 500 mm | 1 | 4mm | ±0.210 mm per 300 mm | 11.5mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M14 | 1,000 mm | 1 | 4mm | ±0.210 mm per 300 mm | 11.5mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M16 | 500 mm | 1 | 5mm | ±0.210 mm per 300 mm | 13.5mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M16 | 1,000 mm | 1 | 5mm | ±0.210 mm per 300 mm | 13.5mm | Rockwell C58 | 21,000 | 5° to 175° | 000000 | 000000 |

| M20 | 500 mm | 1 | 5mm | ±0.210 mm per 300 mm | 17.2mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M20 | 1,000 mm | 1 | 5mm | ±0.210 mm per 300 mm | 17.2mm | Rockwell C58 | 21,000 | 5° to 175° | 000000 | 000000 |

| M20 | 1,500 mm | 1 | 10mm | ±0.210 mm per 300 mm | 16.4mm | Rockwell C58 | 21,000 | 5° to 175° | 000000 | 000000 |

| M25 | 500 mm | 1 | 5mm | ±0.210 mm per 300 mm | 22.2mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M25 | 1,000 mm | 1 | 5mm | ±0.210 mm per 300 mm | 22.2mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| M25 | 1,500 mm | 1 | 10mm | ±0.210 mm per 300 mm | 20.2mm | Rockwell C58 | 21,000 | 5° to 175° | 0000000 | 000000 |

| Thread Size | Lg., mm | Wd., mm | Ht., mm | Center Ht., mm | No. of Thread Starts | Travel Distance per Turn, mm | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash, mm | Temp. Range, °F | Each | |

Alloy Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M14 | 35 | 34 | 30 | 13 | 1 | 4 | Rockwell C58 | 1,200 | 0.1 | 5° to 175° | 0000000 | 0000000 |

| M16 | 36 | 42 | 32.5 | 16 | 1 | 5 | Rockwell C58 | 1,200 | 0.1 | 5° to 175° | 0000000 | 000000 |

| M20 | 35 | 48 | 39 | 17 | 1 | 5 | Rockwell C58 | 1,300 | 0.1 | 5° to 175° | 0000000 | 000000 |

| M20 | 58 | 48 | 46 | 18 | 1 | 10 | Rockwell C58 | 2,350 | 0.1 | 5° to 175° | 0000000 | 000000 |

| M25 | 35 | 60 | 45 | 20 | 1 | 5 | Rockwell C58 | 1,500 | 0.1 | 5° to 175° | 0000000 | 000000 |

| M25 | 94 | 60 | 55 | 23 | 1 | 10 | Rockwell C58 | 7,000 | 0.1 | 5° to 175° | 0000000 | 000000 |

Flange | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | Wd. | Ht. | Thick. | No. of Thread Starts | Travel Distance per Turn | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Each | ||

Alloy Steel | |||||||||||||

| C | M14 | 40mm | 31mm | 50mm | 37mm | 10mm | 1 | 4mm | Rockwell C58 | 1,200 | 0.1mm | 0000000 | 0000000 |

| C | M16 | 40mm | 34mm | 54mm | 40mm | 10mm | 1 | 5mm | Rockwell C58 | 1,200 | 0.1mm | 0000000 | 000000 |

| C | M20 | 40mm | 40mm | 60mm | 46mm | 10mm | 1 | 5mm | Rockwell C58 | 1,300 | 0.1mm | 0000000 | 000000 |

| C | M20 | 64mm | 52mm | 82mm | 64mm | 12mm | 1 | 10mm | Rockwell C58 | 2,350 | 0.1mm | 0000000 | 000000 |

| C | M25 | 40mm | 43mm | 67mm | 50mm | 10mm | 1 | 5mm | Rockwell C58 | 1,500 | 0.1mm | 0000000 | 000000 |

| C | M25 | 98mm | 60mm | 96mm | 72mm | 15mm | 1 | 10mm | Rockwell C58 | 7,000 | 0.1mm | 0000000 | 000000 |

Fast-Travel Ball Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than ball screws with a single thread start. Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. To ensure compatibility, select components that have the same thread size and number of thread starts. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Carbon steel ball screws and nuts are case hardened, so they resist wear better than standard carbon steel. However, they are less corrosion resistant than black-oxide alloy steel screws and nuts.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

For technical drawings and 3-D models, click on a part number.

Root diameter indicates the diameter the ball screw will be after machining away the threads.

| Thread Size | Lg. | No. of Thread Starts | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Root Dia. | Hardness | Tensile Strength, psi | Temperature Range, °F | Each | |

Carbon Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M12 | 500mm | 2 | 10mm | ±0.05 mm per 300 mm | 9.6mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 0000000 |

| M12 | 1,000mm | 2 | 10mm | ±0.05 mm per 300 mm | 9.6mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M15 | 500mm | 4 | 16mm | ±0.05 mm per 300 mm | 12.9mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 00000 |

| M15 | 500mm | 4 | 20mm | ±0.05 mm per 300 mm | 12.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 00000 |

| M15 | 1,000mm | 4 | 16mm | ±0.05 mm per 300 mm | 12.9mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M15 | 1,000mm | 4 | 20mm | ±0.05 mm per 300 mm | 12.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M16 | 500mm | 4 | 16mm | ±0.05 mm per 300 mm | 13.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 00000 |

| M16 | 1,000mm | 4 | 16mm | ±0.05 mm per 300 mm | 13.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M20 | 500mm | 4 | 20mm | ±0.05 mm per 300 mm | 17mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M20 | 1,000mm | 4 | 20mm | ±0.05 mm per 300 mm | 17mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M32 | 500mm | 2 | 20mm | ±0.05 mm per 300 mm | 28.5mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M32 | 500mm | 4 | 32mm | ±0.05 mm per 300 mm | 28.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M32 | 1,000mm | 2 | 20mm | ±0.05 mm per 300 mm | 28.5mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M32 | 1,000mm | 4 | 32mm | ±0.05 mm per 300 mm | 28.3mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M40 | 500mm | 4 | 40mm | ±0.05 mm per 300 mm | 35.4mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| M40 | 1,000mm | 4 | 40mm | ±0.05 mm per 300 mm | 35.4mm | Rockwell C56 | 95,000 | 32° to 150° | 00000000 | 000000 |

| Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Carbon Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | M12 | 50mm | 30mm | 1 | 10mm | M25 | Rockwell C56 | 1,000 | 0.02mm | 32° to 150° | 00000000 | 0000000 |

| B | M16 | 50mm | 39mm | 4 | 16mm | M30 | Rockwell C56 | 1,500 | 0.04mm | 32° to 150° | 00000000 | 000000 |

| C | M32 | 90mm | 53mm | 4 | 32mm | M50 | Rockwell C56 | 3,700 | 0.03mm | 32° to 150° | 00000000 | 000000 |

Flange | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

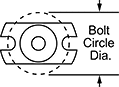

| Thread Size | Lg. | Dia. | Dia. | Thick. | No. of Thread Starts | Travel Distance per Turn | Bolt Circle Dia. | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Carbon Steel | ||||||||||||||

| E | M12 | 43mm | 23mm | 40mm | 10mm | 2 | 10mm | 32mm | Rockwell C56 | 1,100 | 0.02mm | 32° to 150° | 00000000 | 0000000 |

| E | M15 | 56mm | 33mm | 57mm | 10mm | 4 | 20mm | 45mm | Rockwell C56 | 2,250 | 0.04mm | 32° to 150° | 00000000 | 000000 |

| E | M15 | 61mm | 27mm | 48mm | 10mm | 4 | 16mm | 38mm | Rockwell C56 | 2,200 | 0.04mm | 32° to 150° | 00000000 | 000000 |

| E | M20 | 77mm | 35mm | 58mm | 10mm | 4 | 20mm | 47mm | Rockwell C56 | 2,750 | 0.04mm | 32° to 150° | 00000000 | 000000 |

| E | M32 | 88mm | 53mm | 86mm | 14mm | 4 | 32mm | 71mm | Rockwell C56 | 5,800 | 0.05mm | 32° to 150° | 00000000 | 000000 |

| E | M32 | 108mm | 49mm | 80mm | 16mm | 2 | 20mm | 65mm | Rockwell C56 | 4,900 | 0.04mm | 32° to 150° | 00000000 | 000000 |

| E | M40 | 101mm | 66mm | 106mm | 18mm | 4 | 40mm | 85mm | Rockwell C56 | 9,550 | 0.07mm | 32° to 150° | 00000000 | 000000 |

Metric End Supports for Lead Screws and Ball Screws

A set of ball bearings reduces friction and secures the end of a ball or lead screw. End supports handle radial loads (perpendicular to the lead screw) and thrust loads (parallel to the lead screw). Note: The end of your ball or lead screw must be machined before installing it into an end support.

For technical drawings and 3-D models, click on a part number.

Combined Load Cap., lbs. | Top Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ID, mm | Ht., mm | Center Ht., mm | Wd., mm | Dp., mm | Static | Dynamic | Dia. | Ctr.-to-Ctr. Wd., mm | Temperature Range, °F | Each | |

For Combined Radial and Thrust Loads | |||||||||||

Carbon Steel | |||||||||||

| 12 | 43 | 25 | 60 | 34 | 730 | 1,450 | 6.6 | 46 | 0° to 160° | 0000000 | 0000000 |

| 15 | 48 | 28 | 70 | 38 | 890 | 1,700 | 6.6 | 54 | 0° to 160° | 0000000 | 000000 |

| 17 | 64 | 39 | 86 | 51 | 1,300 | 3,050 | 9 | 68 | 0° to 160° | 0000000 | 000000 |

Roller Screws and Nuts

Precision ground to create more points of contact, these roller screws and nuts are highly accurate and handle much higher loads than ball screws and nuts of the same size. They're most traditionally used to replace hydraulics in linear actuators but can also be used in place of ball and lead screw assemblies because of their high load capacity and precise motion control. In fact, they're almost four times more accurate than our most accurate ball and lead screws. They also last longer than ball screw nuts in systems with lower loads and can handle higher shock loads. However, because they have more contact points, they’re slightly less efficient than ball screws. To ensure compatibility, select components that have the same thread direction and size.

Roller screws are made of hardened steel for strength and durability.

Travel distance per turn, also known as screw lead, is the distance a roller nut moves with one revolution of the roller screw.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Lg., mm | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Min. Thread Lg., mm | Root Dia., mm | Hardness | Tensile Strength, psi | Each | |

Alloy Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M15 | 642 | 5 | 4 | ±0.023 mm per 300 mm | 522 | 14.59 | Rockwell C60 | 105,000 | 0000000 | 000000000 |

| M15 | 642 | 5 | 5 | ±0.023 mm per 300 mm | 522 | 14.44 | Rockwell C60 | 105,000 | 0000000 | 00000000 |

| M20 | 680 | 5 | 4 | ±0.023 mm per 300 mm | 561 | 19.15 | Rockwell C60 | 105,000 | 0000000 | 00000000 |

| M20 | 680 | 5 | 5 | ±0.023 mm per 300 mm | 561 | 19.05 | Rockwell C60 | 105,000 | 0000000 | 00000000 |

Keyway | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg., mm | Dia., mm | No. of Thread Starts | Travel Distance per Turn, mm | Wd., mm | Dp., mm | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash, mm | Temp. Range, °F | Lubrication | Each | |

Alloy Steel | |||||||||||||

| M15 | 45 | 35 | 5 | 4 | 4 | 14 | Rockwell C60 | 9,230 | 0.03 | -40° to 350° | Required | 0000000 | 000000000 |

| M15 | 45 | 35 | 5 | 5 | 4 | 14 | Rockwell C60 | 12,000 | 0.03 | -40° to 350° | Required | 0000000 | 00000000 |

| M20 | 65 | 42 | 5 | 4 | 4 | 18 | Rockwell C60 | 15,100 | 0.03 | -40° to 350° | Required | 0000000 | 00000000 |

| M20 | 65 | 42 | 5 | 5 | 4 | 18 | Rockwell C60 | 20,600 | 0.03 | -40° to 350° | Required | 0000000 | 00000000 |

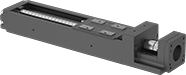

Positioning Slides for Stepper Motors

Add your own stepper motor and controller to precisely move the ball screw and carriage smoothly at high speeds, like a head on an inkjet printer. With a repeatability of ± 0.01 mm—thinner than a strand of hair—the carriage hits the same spot every time. These positioning slides work well for automated assemblies and other applications that require fine, repeatable motion control.

The carriage rides along the inside of the rail, making these slides more compact than traditional carriages and guide rails. Made of steel with a U-shaped rail, these slides resist twisting forces that could affect their positioning. This also means they can be installed with only one end supported or with both ends overhanging. The same load rating applies no matter how the slides are oriented.

Two-axis mounting plates (sold separately) secure two slides together for motion along two axes.

Travel distance per turn, also known as screw lead, is how far the carriage moves with one rotation of the ball screw.

For technical drawings and 3-D models, click on a part number.

Dynamic Load Capacity, lbs. | Overall | Carriage | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg., mm | Horizontal | Vertical | Max. Speed, mm/s | Travel Distance per Turn, mm | Repeatability, mm | For Shaft Dia. | For Max. Motor Speed, rpm | For Max. Motor Torque, in.-oz. | Lg., mm | Wd., mm | Ht., mm | Lg., mm | Wd., mm | Bearing Type | Base Material | Each | |

For NEMA 14 Motor Frame Size | |||||||||||||||||

| 30 | 148 | 148 | 100 | 1 | ±0.01 | 5mm | 6,000 | 29.3 | 166 | 40 | 42 | 46 | 23 | Ball | Steel | 00000000 | 0000000 |

| 80 | 148 | 148 | 100 | 1 | ±0.01 | 5mm | 6,000 | 29.3 | 216 | 40 | 42 | 46 | 23 | Ball | Steel | 00000000 | 00000000 |

| 110 | 528 | 528 | 200 | 2 | ±0.01 | 5mm | 6,000 | 88.1 | 276 | 50 | 36 | 47.4 | 31 | Ball | Steel | 00000000 | 00000000 |

| 130 | 148 | 148 | 100 | 1 | ±0.01 | 5mm | 6,000 | 29.3 | 266 | 40 | 42 | 46 | 23 | Ball | Steel | 00000000 | 00000000 |

For NEMA 17 Motor Frame Size | |||||||||||||||||

| 100 | 402 | 402 | 470 | 6 | ±0.01 | 5mm | 4,700 | 176 | 277 | 60 | 44.5 | 76 | 37.4 | Ball | Steel | 00000000 | 00000000 |

| 110 | 528 | 528 | 200 | 2 | ±0.01 | 5mm | 6,000 | 88.1 | 276.5 | 50 | 42 | 47.4 | 31 | Ball | Steel | 00000000 | 00000000 |

| 160 | 528 | 528 | 200 | 2 | ±0.01 | 5mm | 6,000 | 88.1 | 326.5 | 50 | 42 | 47.4 | 31 | Ball | Steel | 00000000 | 00000000 |

| 200 | 402 | 402 | 470 | 6 | ±0.01 | 5mm | 4,700 | 176 | 377 | 60 | 44.5 | 76 | 37.4 | Ball | Steel | 00000000 | 00000000 |

| 210 | 528 | 528 | 200 | 2 | ±0.01 | 5mm | 6,000 | 88.1 | 376.5 | 50 | 42 | 47.4 | 31 | Ball | Steel | 00000000 | 00000000 |

Dry-Running Positioning Slides for Stepper Motors

With PTFE sleeve bearings and a low-friction ball screw, these slides don’t require the mess and maintenance of lubrication but still give you precise positioning anywhere along the length of their stroke. Because they have sleeve bearings, they have fewer moving parts, so they perform better in dusty and wet environments than slides with ball bearings. They’re also better at handling impact and vibration.

All slides require a stepper motor, driver, and controller (not included) to operate. As part of this system, they move in precise increments, like the head on an inkjet printer. These positioning slides work well for automated assemblies and other applications that require fine, repeatable motion control.

Travel distance per turn, also known as screw lead, is how far the carriage moves with one rotation of the ball screw.

For technical drawings and 3-D models, click on a part number.

Overall | Carriage | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg., mm | Dynamic Horizontal/Vertical Load Capacity, lbs. | Static Load Capacity, lbs. | Max. Speed, mm/s | Travel Distance per Turn, mm | Repeatability, mm | For Shaft Dia. | For Max. Motor Speed, rpm | For Max. Motor Torque, in.-oz. | Lg., mm | Wd., mm | Ht., mm | Lg., mm | Wd., mm | Bearing Type | Base Material | Each | |

For NEMA 17 Motor Frame Size | |||||||||||||||||

| 100 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 276 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 0000000 |

| 200 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 376 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 000000 |

| 300 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 476 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 000000 |

| 400 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 576 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 000000 |

| 500 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 676 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 000000 |

| 600 | Not Rated | 630 | 50 | 2 | ±0.1 | 5mm | 1,500 | 71 | 776 | 74 | 56 | 69 | 73 | Sleeve | Aluminum | 0000000 | 000000 |

Ball Screw/Splines and Bearings

From one compact system, transmit linear or rotary motion or both at once (sometimes called spiral motion). Because of these different motions, these ball screw/splines and bearings create efficient, fluid movements in complex automated applications, such as pick-and-place robots.

The ball bearings move smoothly and precisely, even at high speeds. They're powered independently, so you can drive one bearing at a time or both together to coordinate movements.

The ball screw/splines are hardened on the surface, so they stand up to repeated motion. They’re also hollow, so you can run electrical wiring, compressed air tubing, coolants, or lubricant through their center.

For technical drawings and 3-D models, click on a part number.

Spline | Thread | Ball Screw Bearing | Ball Spline Bearing | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | No. of | Lg. | Direction | ID, mm | Lg., mm | Root Dia., mm | OD, mm | Overall Lg., mm | Dynamic Load Cap., lbs. | Static Load Cap., lbs. | OD, mm | Overall Lg., mm | Dynamic Load Cap., lbs. | Static Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | Temp. Range, ° F | Each | |

Metric—1055 Carbon Steel | ||||||||||||||||||

8mm Dia. (Tolerance: -0.015mm to 0mm) | ||||||||||||||||||

| 200 mm | 4 | 180 mm | Right Hand | 3 | 200 | 7.44 | 19 | 28.5 | 240 | 400 | 16 | 25 | 330 | 580 | 17 | 5° to 176° | 0000000 | 000000000 |

10mm Dia. (Tolerance: -0.015mm to 0mm) | ||||||||||||||||||

| 300 mm | 4 | 270 mm | Right Hand | 4 | 300 | 9.27 | 23 | 34.5 | 380 | 600 | 21 | 33 | 600 | 1,100 | 34 | 5° to 176° | 0000000 | 00000000 |

16mm Dia. (Tolerance: -0.018mm to 0mm) | ||||||||||||||||||

| 500 mm | 6 | 360 mm | Right Hand | 11 | 500 | 15.15 | 32 | 40 | 870 | 1,610 | 31 | 50 | 1,590 | 2,830 | 277 | 5° to 176° | 0000000 | 00000000 |

Metric Alloy Steel Low-Profile Swivel-Tip Set Screws

A low-profile flat-faced ball tip allows these set screw to be used in low-clearance applications. They're also known as ball-ended thrust screws. Length listed is the overall length.

For technical drawings and 3-D models, click on a part number.

| Lg., mm | Tip Dia., mm | Max. Swivel Angle | Drive Size, mm | Hardness | Each | |

Alloy Steel | ||||||

|---|---|---|---|---|---|---|

M5 × 0.8 mm | ||||||

| 9.5 | 2.2 | 9° | 2.5 | Rockwell C39 | 000000000 | 00000 |

| 15.5 | 2.2 | 9° | 2.5 | Rockwell C39 | 000000000 | 00000 |

| 24.5 | 2.2 | 9° | 2.5 | Rockwell C39 | 000000000 | 00000 |

M6 × 1 mm | ||||||

| 16 | 3.2 | 9° | 3 | Rockwell C39 | 000000000 | 0000 |

| 20 | 3.2 | 9° | 3 | Rockwell C39 | 000000000 | 0000 |

| 25 | 3.2 | 9° | 3 | Rockwell C39 | 000000000 | 0000 |

M8 × 1.25 mm | ||||||

| 20 | 4.5 | 9° | 4 | Rockwell C39 | 000000000 | 00000 |

| 25 | 4.5 | 9° | 4 | Rockwell C39 | 000000000 | 00000 |

| 30 | 4.5 | 9° | 4 | Rockwell C39 | 000000000 | 00000 |

M10 × 1.5 mm | ||||||

| 16 | 6 | 9° | 5 | Rockwell C39 | 000000000 | 00000 |

| 25 | 6 | 9° | 5 | Rockwell C39 | 000000000 | 00000 |

| 35 | 6 | 9° | 5 | Rockwell C39 | 000000000 | 00000 |

M12 × 1.75 mm | ||||||

| 16 | 7.2 | 9° | 6 | Rockwell C39 | 000000000 | 00000 |

| 30 | 7.2 | 9° | 6 | Rockwell C39 | 000000000 | 00000 |

| 40 | 7.2 | 9° | 6 | Rockwell C39 | 000000000 | 00000 |

Swiveling Tips for Screws and Threaded Studs

Attach to the end of a screw or threaded stud to apply uniform pressure on uneven and angled surfaces. Also known as toggle and swivel-foot pads.

For technical drawings and 3-D models, click on a part number.