Filter by

Body Diameter

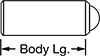

Body Length

Nose Diameter

Nose Material

Body Material

Extended Nose Force

Extended Nose Length

Compressed Nose Force

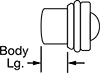

Flange Diameter

Locking Type

Flange Thickness

Fastener Head Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Handle Material

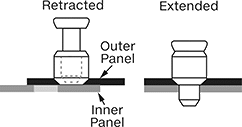

Press-Fit Ball-Nose Spring Plungers

Nose | Nose Force, lbf | Body | Flange | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Lg. | Dia. | Extended | Compressed | Material | Texture | Dia. | Lg. | Thick. | Dia. | 1-99 | 100-499 | 500-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

440C Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | Zinc Black-Chromate Plated Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | Zinc Black-Chromate Plated Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.04" | 0.12" | 0.6 | 1.4 | 18-8 Stainless Steel | Smooth | 0.157" | 0.16" | 3/64" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | Zinc Black-Chromate Plated Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | Zinc Black-Chromate Plated Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.06" | 0.16" | 0.7 | 1.5 | 18-8 Stainless Steel | Smooth | 0.2" | 0.2" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | Zinc Black-Chromate Plated Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | Zinc Black-Chromate Plated Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | 18-8 Stainless Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.2" | 1.2 | 2.6 | 18-8 Stainless Steel | Smooth | 0.24" | 0.24" | 3/64" | 1/4" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | Black-Oxide Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | Black-Oxide Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.26" | 1.6 | 2.8 | 18-8 Stainless Steel | Smooth | 0.31" | 0.31" | 3/64" | 5/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | Zinc Black-Chromate Plated Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | Zinc Black-Chromate Plated Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.13" | 0.33" | 1.9 | 4.2 | 18-8 Stainless Steel | Smooth | 0.394" | 0.45" | 1/16" | 7/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.16" | 0.39" | 2.7 | 6 | 18-8 Stainless Steel | Smooth | 0.472" | 0.54" | 3/32" | 1/2" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | Black-Oxide Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | Black-Oxide Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | 18-8 Stainless Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 00000000 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

420 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.55 mm | 2 mm | 0.4 | 0.8 | Acetal | Smooth | 3 mm | 3.4 mm | 0.6 mm | 3.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.6 mm | 2.4 mm | 0.4 | 0.8 | Brass | Smooth | 3 mm | 3.4 mm | 0.6 mm | 3.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 mm | 2.4 mm | 0.4 | 0.8 | 18-8 Stainless Steel | Smooth | 3 mm | 3.4 mm | 0.6 mm | 3.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 3 mm | 0.7 | 1.3 | Acetal | Smooth | 4 mm | 4 mm | 1 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 3 mm | 0.7 | 1.3 | Brass | Smooth | 4 mm | 4 mm | 1 mm | 4.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.9 mm | 3 mm | 2.9 | 4.3 | 18-8 Stainless Steel | Smooth | 4 mm | 9.8 mm | 0.9 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 3 mm | 0.1 | 0.2 | 18-8 Stainless Steel | Smooth | 4 mm | 4.1 mm | 0.9 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 3 mm | 0.6 | 1.3 | 18-8 Stainless Steel | Smooth | 4 mm | 4.1 mm | 0.9 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 3 mm | 1.1 | 2.3 | 18-8 Stainless Steel | Smooth | 4 mm | 4.1 mm | 0.9 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 4 mm | 0.9 | 1.5 | Brass | Smooth | 5 mm | 5 mm | 1 mm | 5.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 4 mm | 1.3 | 2.1 | Acetal | Smooth | 5 mm | 5 mm | 1 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.3 mm | 4 mm | 4.3 | 6.6 | 18-8 Stainless Steel | Smooth | 5 mm | 11.1 mm | 0.9 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.4 mm | 4 mm | 0.1 | 1.1 | 18-8 Stainless Steel | Smooth | 5 mm | 5.1 mm | 0.9 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.4 mm | 4 mm | 0.7 | 1.5 | 18-8 Stainless Steel | Smooth | 5 mm | 5.1 mm | 0.9 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.4 mm | 4 mm | 1.1 | 2.7 | 18-8 Stainless Steel | Smooth | 5 mm | 5.1 mm | 0.9 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm | 5 mm | 1.3 | 2.6 | Brass | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm | 5 mm | 1.4 | 2.8 | Acetal | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.7 mm | 5 mm | 6.3 | 10.7 | 18-8 Stainless Steel | Smooth | 6 mm | 14 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.8 mm | 5 mm | 0.5 | 1.5 | 18-8 Stainless Steel | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.8 mm | 5 mm | 1.2 | 2.6 | 18-8 Stainless Steel | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.8 mm | 5 mm | 1.6 | 4.3 | 18-8 Stainless Steel | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9 mm | 6.5 mm | 1.8 | 2.8 | Brass | Smooth | 8 mm | 8 mm | 1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9 mm | 6.5 mm | 2.2 | 4.6 | Acetal | Smooth | 8 mm | 8 mm | 1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.3 mm | 6.5 mm | 9 | 15.1 | 18-8 Stainless Steel | Smooth | 8 mm | 16.9 mm | 1.1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 6.5 mm | 0.9 | 2 | 18-8 Stainless Steel | Smooth | 8 mm | 7.9 mm | 1.1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 6.5 mm | 1.6 | 2.8 | 18-8 Stainless Steel | Smooth | 8 mm | 7.9 mm | 1.1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 6.5 mm | 2.5 | 5.6 | 18-8 Stainless Steel | Smooth | 8 mm | 7.9 mm | 1.1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 8 mm | 2.7 | 5 | Acetal | Smooth | 10 mm | 12 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.1 mm | 8.5 mm | 14.8 | 23.6 | 18-8 Stainless Steel | Smooth | 10 mm | 24.5 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 8.5 mm | 0.9 | 2.2 | 18-8 Stainless Steel | Smooth | 10 mm | 11.5 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 8.5 mm | 1.9 | 4.2 | 18-8 Stainless Steel | Smooth | 10 mm | 11.5 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 8.5 mm | 3.8 | 8.3 | 18-8 Stainless Steel | Smooth | 10 mm | 11.5 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 10 mm | 3.1 | 5.6 | Acetal | Smooth | 12 mm | 14.5 mm | 1.5 mm | 13 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 10 mm | 1.4 | 3.3 | 18-8 Stainless Steel | Smooth | 12 mm | 13.7 mm | 2.3 mm | 13 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 10 mm | 2.7 | 6 | 18-8 Stainless Steel | Smooth | 12 mm | 13.7 mm | 2.3 mm | 13 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 10 mm | 6.7 | 12.1 | 18-8 Stainless Steel | Smooth | 12 mm | 13.7 mm | 2.3 mm | 13 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 0.8 | 2 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | 18-8 Stainless Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | 18-8 Stainless Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 3 mm | 0.7 | 1.5 | Acetal | Smooth | 4 mm | 4 mm | 1 mm | 4.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 4 mm | 1.3 | 2.1 | Acetal | Smooth | 5 mm | 5 mm | 1 mm | 5.6 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm | 5 mm | 1.4 | 2.8 | Acetal | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9 mm | 6.5 mm | 2.2 | 4.6 | Acetal | Smooth | 8 mm | 8 mm | 1 mm | 8.5 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 8 mm | 2.7 | 5 | Acetal | Smooth | 10 mm | 12 mm | 1.5 mm | 11 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 10 mm | 3.1 | 5.6 | Acetal | Smooth | 12 mm | 14.5 mm | 1.5 mm | 13 mm | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flush Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

440C Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | 18-8 Stainless Steel | Knurled | 0.148" | 0.29" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | Black-Oxide Steel | Knurled | 0.148" | 0.29" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | 18-8 Stainless Steel | Knurled | 0.21" | 0.44" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | Black-Oxide Steel | Knurled | 0.21" | 0.44" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.188" | 1.5 | 3.5 | 18-8 Stainless Steel | Knurled | 0.254" | 0.52" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.188" | 1.5 | 3.5 | Black-Oxide Steel | Knurled | 0.254" | 0.52" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.188" | 3 | 7 | 18-8 Stainless Steel | Knurled | 0.254" | 0.52" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.188" | 3 | 7 | Black-Oxide Steel | Knurled | 0.254" | 0.52" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | 18-8 Stainless Steel | Knurled | 0.316" | 0.7" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | Black-Oxide Steel | Knurled | 0.316" | 0.7" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | 18-8 Stainless Steel | Knurled | 0.316" | 0.7" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | Black-Oxide Steel | Knurled | 0.316" | 0.7" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | 18-8 Stainless Steel | Knurled | 0.379" | 0.87" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | Black-Oxide Steel | Knurled | 0.379" | 0.87" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.313" | 2.5 | 7 | 18-8 Stainless Steel | Knurled | 0.379" | 0.87" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.313" | 2.5 | 7 | Black-Oxide Steel | Knurled | 0.379" | 0.87" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | Black-Oxide Steel | Knurled | 0.504" | 1.21" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.438" | 4 | 9 | 18-8 Stainless Steel | Knurled | 0.504" | 1.21" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.438" | 4 | 9 | Black-Oxide Steel | Knurled | 0.504" | 1.21" | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

420 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.65 mm | 2 mm | 1 | 1.7 | 18-8 Stainless Steel | Smooth | 3 mm | 7 mm | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 2.5 mm | 1.3 | 3.2 | 18-8 Stainless Steel | Smooth | 3.5 mm | 9 mm | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.9 mm | 3 mm | 1.8 | 3.2 | 18-8 Stainless Steel | Smooth | 4 mm | 11 mm | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 3.5 mm | 2.5 | 4 | 18-8 Stainless Steel | Smooth | 5 mm | 13 mm | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 mm | 4.5 mm | 4 | 7 | 18-8 Stainless Steel | Smooth | 6 mm | 15 mm | — | — | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

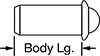

Press-Fit Long-Nose Spring Plungers

Nose | Nose Force, lbf | Body | Flange | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Lg. | Dia. | Extended | Compressed | Material | Dia. | Lg. | Thick. | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.062" | 0.07" | 1 | 2 | Black-Oxide Steel | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 0.8 | 2 | Black-Oxide Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 1.5 | 4.5 | Black-Oxide Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 1.3 | 3 | Black-Oxide Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 2.5 | 6 | Black-Oxide Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.151" | 0.186" | 4 | 10 | Black-Oxide Steel | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 2.5 | 7 | Black-Oxide Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 5 | 14 | Black-Oxide Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 4 | 9 | Black-Oxide Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 8 | 18 | Black-Oxide Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.062" | 0.07" | 1 | 2 | 18-8 Stainless Steel | 0.125" | 0.25" | 1/32" | 3/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 0.8 | 2 | 18-8 Stainless Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 1.3 | 3 | 18-8 Stainless Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 2.5 | 6 | 18-8 Stainless Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.151" | 0.186" | 4 | 10 | 18-8 Stainless Steel | 0.312" | 0.64" | 3/64" | 3/8" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 2.5 | 7 | 18-8 Stainless Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 5 | 14 | 18-8 Stainless Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 4 | 9 | 18-8 Stainless Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 8 | 18 | 18-8 Stainless Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 0.8 | 2 | 18-8 Stainless Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 0.8 | 2 | Black-Oxide Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | 0.121" | 1.5 | 4.5 | Black-Oxide Steel | 0.188" | 0.44" | 3/64" | 1/4" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 1.3 | 3 | 18-8 Stainless Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 1.3 | 3 | Black-Oxide Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 2.5 | 6 | 18-8 Stainless Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.168" | 2.5 | 6 | Black-Oxide Steel | 0.25" | 0.52" | 1/16" | 5/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 2.5 | 7 | 18-8 Stainless Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 2.5 | 7 | Black-Oxide Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 5 | 14 | 18-8 Stainless Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.234" | 5 | 14 | Black-Oxide Steel | 0.375" | 0.79" | 3/32" | 1/2" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 4 | 9 | 18-8 Stainless Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 4 | 9 | Black-Oxide Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 8 | 18 | 18-8 Stainless Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.332" | 8 | 18 | Black-Oxide Steel | 0.5" | 1.1" | 1/8" | 11/16" | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flush Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.125" | 0.5 | 0.9 | 2011 Aluminum | 0.25" | 0.63" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.438" | 0.25" | 0.3 | 1.1 | 2011 Aluminum | 0.34" | 0.81" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.125" | 0.3 | 1 | 2011 Aluminum | 0.25" | 0.75" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.125" | 0.3 | 1.1 | 2011 Aluminum | 0.25" | 0.75" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.188" | 0.3 | 1.5 | 2011 Aluminum | 0.31" | 0.75" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.094" | 0.3 | 1.1 | 2011 Aluminum | 0.25" | 1" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.125" | 0.3 | 0.8 | 2011 Aluminum | 0.25" | 1" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.125" | 0.3 | 0.9 | 2011 Aluminum | 0.25" | 1" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.156" | 0.2 | 0.7 | 2011 Aluminum | 0.25" | 1" | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.813" | 0.125" | 0.3 | 1.1 | 2011 Aluminum | 0.25" | 1.25" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tight-Hold Ball-Nose Spring Plungers

Nose | Nose Force, lbf | Body | Flange | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Lg. | Dia. | Extended | Compressed | Material | Dia. | Lg. | Thick. | Dia. | O-Ring Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | 0.118" | 0.7 | 1.6 | 18-8 Stainless Steel | 0.158" | 0.11" | 3/32" | 3/16" | Buna-N | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 0.158" | 0.9 | 1.6 | 18-8 Stainless Steel | 0.197" | 0.15" | 3/32" | 1/4" | Buna-N | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.059" | 0.197" | 1.3 | 2.7 | 18-8 Stainless Steel | 0.236" | 0.13" | 5/32" | 5/16" | Buna-N | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.071" | 0.256" | 1.3 | 2.7 | 18-8 Stainless Steel | 0.315" | 0.19" | 11/64" | 3/8" | Buna-N | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.106" | 0.315" | 2.2 | 4.5 | 18-8 Stainless Steel | 0.394" | 0.32" | 13/64" | 1/2" | Buna-N | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.138" | 0.394" | 3.4 | 5.6 | 18-8 Stainless Steel | 0.473" | 0.41" | 7/32" | 0.549" | Buna-N | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

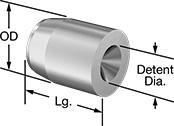

Press-Fit Catches for Ball-Nose Spring Plungers

|

440C Stainless Steel | ||||||

|---|---|---|---|---|---|---|

For Nose Dia. | Lg. | OD | Detent Dia. | Each | ||

| 0.062" | 1/8" | 0.108" | 0.056" | 00000000 | 00000 | |

| 0.078" | 1/8" | 0.118" | 0.061" | 00000000 | 0000 | |

| 0.094" | 3/16" | 0.161" | 0.069" | 00000000 | 0000 | |

| 0.125" | 1/4" | 0.203" | 0.111" | 00000000 | 0000 | |

| 0.156" | 5/16" | 0.266" | 0.139" | 00000000 | 0000 | |

| 0.188" | 3/8" | 0.328" | 0.164" | 00000000 | 0000 | |

| 0.281" | 1/2" | 0.438" | 0.241" | 00000000 | 0000 | |

| 0.375" | 5/8" | 0.547" | 0.33" | 00000000 | 0000 | |