Filter by

System of Measurement

For Motion

Mechanical Finish

Step Length

Edge Type

Hardness Rating

Hardness

Export Control Classification Number (ECCN)

REACH

DFARS Specialty Metals

RoHS

About Shafts

More

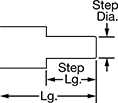

Step-Down Rotary Shafts

A shoulder near the end of the shaft provides a stop for gears, sprockets, and bearings. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances.

1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use. They are stronger than aluminum and stainless steel shafts but not as corrosion resistant. 303 stainless steel shafts are more corrosion resistant than steel shafts but also more difficult to machine.

Step Down × Straight End

Step-Down End × Straight End

Step | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Dia. | Lg. | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||

3/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 6" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 000000 |

| 9" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 00000 |

| 12" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 00000 |

1" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 6" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 00000 |

| 9" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 00000 |

| 12" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 000000 | 00000 |

Inch—303 Stainless Steel | |||||||||

3/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 6" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

| 9" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

| 12" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

1" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 6" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

| 9" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

| 12" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 160 | 0000000 | 00000 |

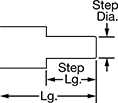

Step-Down on Both Ends

Step-Down on Both Ends

Step | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Dia. | Lg. | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||

3/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 000000 |

| 18" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 24" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

1" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 12" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 18" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 18" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 24" | -0.005" to 0.005" | 1/2" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |

| 24" | -0.005" to 0.005" | 3/4" | 3" | 0.003" per ft. | Chamfered | Medium | Brinell 150 | 0000000 | 00000 |