About Shafts

More

Splined Rotary Shafts

Good for hydraulic systems, machine tools, and other high-torque applications, these shafts have teeth that transmit high rotational loads. Compared to keyed shafts, they last longer and handle higher torque. They’re also better than keyed shafts for applications requiring frequent disassembly or adjustments because you can move bushings along their splines.

Parallel splines have large, straight-sided teeth that resemble machine keys and transmit more torque than involute spline teeth. These splines are known as straight splines.

Involute splines have curved teeth, similar to the teeth on a gear. These teeth make more contact with a bushing than the teeth on parallel splines, so these splines are less prone to wear. They handle misalignment and reduce vibration.

Straight ends have a smooth, round finish instead of splines. Use this end with gears, sprockets, and bearings.

Bushings act as a surface to transmit rotary motion or to position a load along the length of the shaft. If welded into place, these bushings can act as a coupler, connecting two splined shafts. Flanged bushings have a surface with mounting holes for you to attach your load.

For technical drawings and 3-D models, click on a part number.

Shafts | Flanged Bushings | Sleeve Bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Spline Lg. | No. of Splines | Lg. | Edge Type | Hardness Rating | Hardness | Specifications Met | Each | Each | Each | |||

Inch—1215 Carbon Steel | |||||||||||||

| 1" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 0000000 | 000000 | 00 | 0000000 | 000000 |

| 1 1/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 00000 |

| 1 1/4" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 000000 |

| 1 1/4" | 10" | 10 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 000000 |

| 1 3/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 00000 |

| 1 1/2" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 000000 |

| 1 5/8" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 000000 |

| 1 3/4" | 10" | 6 | 10" | Chamfered | Not Rated | Not Rated | __ | 0000000 | 000000 | 000000 | 00 | 0000000 | 000000 |

Metric—1045 Carbon Steel | |||||||||||||

| 20mm | 1,000mm | 6 | 1,000mm | Chamfered | Not Rated | Not Rated | DIN 5463-B, ISO 14-B | 000000000 | 000000 | 000000000 | 0000000 | 000000000 | 000000 |

| 25mm | 1,000mm | 6 | 1,000mm | Chamfered | Not Rated | Not Rated | DIN 5463-B, ISO 14-B | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 32mm | 1,000mm | 6 | 1,000mm | Chamfered | Not Rated | Not Rated | DIN 5463-B, ISO 14-B | 000000000 | 000000 | 000000 | 00 | 000000000 | 000000 |

Shafts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Splined End | Sleeve Bushings | ||||||||||

| Dia. | Lg. | No. of Splines | Straight End Dia. | Lg. | Edge Type | Hardness Rating | Hardness | Each | Each | ||

Inch—1045 Carbon Steel | |||||||||||

| 3/4" | 12" | 6 | 1" | 48" | Chamfered | Medium | Rockwell C15 | 000000 | 0000000 | 0000000 | 000000 |

| 1" | 12" | 6 | 1 1/2" | 48" | Chamfered | Medium | Rockwell C15 | 000000 | 000000 | 0000000 | 00000 |

| 1 1/2" | 12" | 6 | 2" | 48" | Chamfered | Medium | Rockwell C15 | 000000 | 000000 | 0000000 | 000000 |

Shafts | Sleeve Bushings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Spline Lg. | No. of Splines | Lg. | Pitch | Pressure Angle | Edge Type | Hardness Rating | Hardness | Each | Each | ||

Inch—1215 Carbon Steel | ||||||||||||

| 5/8" | 6" | 9 | 6" | 0.563" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 0000000 | 0000000 | 000000 |

| 7/8" | 6" | 13 | 6" | 0.813" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1" | 8" | 15 | 8" | 0.938" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 1/4" | 10" | 14 | 10" | 1.167" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/8" | 10" | 21 | 10" | 1.313" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | 10" | 13 | 10" | 1.625" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | 10" | 27 | 10" | 1.688" | 30° | Chamfered | Not Rated | Not Rated | 0000000 | 000000 | 0000000 | 000000 |

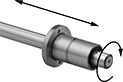

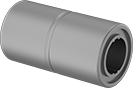

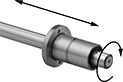

Ball Splines and Bearings

Create a compact linear and rotary motion system for applications requiring complex, fast movements, such as robotics. The grooves on the ball splines transmit rotary power as ball bearings move smoothly and precisely along their length, even at high speeds.

Ball splines are alloy steel for high strength and wear resistance. They're hardened on the outside for additional wear resistance while the center is soft enough to absorb stress from shifting loads. Those with a step-down end have a shoulder near the end to stop gears, sprockets, and bearings.

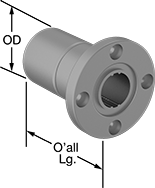

Bearings have a retaining ring groove, so they can be positioned in your system with a retaining ring (not included). Bearings with a keyway include a machine key for attaching your load. Flanged bearings have a surface with mounting holes for attaching your load. Stainless steel bearings are more corrosion resistant than steel bearings.

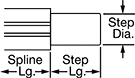

Spline | Step | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Dia. Tolerance, mm | Lg., mm | Lg. Tolerance, mm | Lg., mm | No. of | Root Dia., mm | Dia., mm | Dia. Tolerance, mm | Lg., mm | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—52100 Alloy Steel | ||||||||||||||||

Splined on Both Ends | ||||||||||||||||

| 6 | -0.012 to 0 | 150 | -0.7874 to 0.7874 | 150 | 4 | 5.3 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 0000000 |

| 6 | -0.01 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 5.3 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 6 | -0.01 to 0 | 300 | -0.05 to 0.05 | 300 | 4 | 5.3 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 8 | -0.015 to 0 | 150 | -0.7874 to 0.7874 | 150 | 4 | 7.2 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 8 | -0.01 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 7.2 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 10 | -0.015 to 0 | 200 | -0.7874 to 0.7874 | 200 | 4 | 9 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 10 | -0.02 to 0 | 300 | -0.05 to 0.05 | 300 | 4 | 9 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 10 | -0.02 to 0 | 600 | -0.08 to 0.08 | 600 | 4 | 9 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 13 | -0.02 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 11.7 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 00000 |

| 13 | -0.02 to 0 | 500 | -0.08 to 0.08 | 500 | 4 | 11.7 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 13 | -0.02 to 0 | 700 | -0.08 to 0.08 | 700 | 4 | 11.7 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 16 | -0.02 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 14.2 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 16 | -0.02 to 0 | 700 | -0.08 to 0.08 | 700 | 4 | 14.2 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 20 | -0.02 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 17.9 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 20 | -0.02 to 0 | 2,000 | -0.08 to 0.08 | 2,000 | 4 | 17.9 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 25 | -0.02 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 22.4 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 25 | -0.02 to 0 | 500 | -0.08 to 0.08 | 500 | 4 | 22.4 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 30 | -0.02 to 0 | 300 | -0.05 to 0.05 | 300 | 4 | 26.8 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 30 | -0.02 to 0 | 1,000 | -0.08 to 0.08 | 1,000 | 4 | 26.8 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 30 | -0.02 to 0 | 2,000 | -0.08 to 0.08 | 2,000 | 4 | 26.8 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 00000000 |

| 40 | -0.02 to 0 | 400 | -0.05 to 0.05 | 400 | 4 | 35.5 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 40 | -0.02 to 0 | 700 | -0.08 to 0.08 | 700 | 4 | 35.5 | __ | __ | __ | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

Splined End × Step-Down End | ||||||||||||||||

| 18.2 | -0.021 to 0 | 350 | -0.7874 to 0.7874 | 200 | 4 | 16.4 | 15 | -0.018 to 0 | 150 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 23 | -0.021 to 0 | 350 | -0.7874 to 0.7874 | 200 | 4 | 20.6 | 20 | -0.021 to 0 | 150 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 28 | -0.021 to 0 | 450 | -0.7874 to 0.7874 | 300 | 4 | 24.8 | 25 | -0.021 to 0 | 150 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 37.4 | -0.025 to 0 | 550 | -0.7874 to 0.7874 | 400 | 4 | 33.1 | 30 | -0.021 to 0 | 150 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

Material | Keyway | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | Includes | Dp., mm | Lg., mm | Wd., mm | Each | |

| 6 | 4 | 25 | 14 | Steel | Steel | 270 | 13 | Yes | Machine Key | 1.2 | 10.5 | 2.5 | 00000000 | 000000 |

| 6 | 4 | 25 | 14 | Stainless Steel | Stainless Steel | 270 | 13 | Yes | Machine Key | 1.2 | 10.5 | 2.5 | 00000000 | 000000 |

| 8 | 4 | 25 | 16 | Steel | Steel | 325 | 18 | Yes | Machine Key | 1.2 | 10.5 | 2.5 | 00000000 | 00000 |

| 10 | 4 | 33 | 21 | Steel | Steel | 610 | 38 | Yes | Machine Key | 1.5 | 13 | 3 | 00000000 | 00000 |

| 13 | 4 | 36 | 24 | Steel | Steel | 600 | 185 | Yes | Machine Key | 1.5 | 15 | 3 | 00000000 | 00000 |

| 13 | 4 | 36 | 24 | Stainless Steel | Stainless Steel | 600 | 185 | Yes | Machine Key | 1.5 | 15 | 3 | 00000000 | 000000 |

| 16 | 4 | 50 | 31 | Steel | Steel | 1,350 | 531 | Yes | Machine Key | 2 | 17.5 | 3.5 | 00000000 | 00000 |

| 18.2 | 4 | 60 | 32 | Steel | Steel | 1,750 | 734 | Yes | Machine Key | 2.5 | 26 | 4 | 00000000 | 000000 |

| 25 | 4 | 71 | 42 | Steel | Steel | 2,850 | 1,672 | Yes | Machine Key | 2.5 | 36 | 4 | 00000000 | 000000 |

| 28 | 4 | 80 | 45 | Steel | Steel | 4,150 | 2,557 | Yes | Machine Key | 4 | 41 | 7 | 00000000 | 000000 |

| 30 | 4 | 80 | 47 | Steel | Steel | 4,150 | 2,716 | Yes | Machine Key | 2.5 | 42 | 4 | 00000000 | 000000 |

| 40 | 4 | 100 | 64 | Steel | Steel | 6,900 | 5,964 | Yes | Machine Key | 3.5 | 52 | 6 | 00000000 | 000000 |

Material | Mounting Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | Flange OD, mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | No. of | Thread Size | Each | |

| 6 | 4 | 25 | 30 | 14 | Steel | Steel | 270 | 13 | Yes | 4 | M3 × 0.5 mm | 00000000 | 000000 |

| 8 | 4 | 25 | 32 | 16 | Steel | Steel | 325 | 18 | Yes | 4 | M3 × 0.5 mm | 00000000 | 00000 |

| 10 | 4 | 33 | 42 | 21 | Steel | Steel | 610 | 38 | Yes | 4 | M4 × 0.7 mm | 00000000 | 000000 |

| 13 | 4 | 36 | 43 | 24 | Steel | Steel | 600 | 185 | Yes | 4 | M4 × 0.7 mm | 000000000 | 00000 |

| 16 | 4 | 50 | 50 | 31 | Steel | Steel | 1,350 | 531 | Yes | 4 | M4 × 0.7 mm | 000000000 | 000000 |

| 18.2 | 4 | 60 | 51 | 32 | Steel | Steel | 1,750 | 734 | Yes | 4 | M4 × 0.7 mm | 00000000 | 000000 |

| 20 | 4 | 63 | 58 | 35 | Steel | Steel | 2,000 | 929 | Yes | 4 | M5 × 0.8 mm | 000000000 | 000000 |

| 23 | 4 | 70 | 60 | 37 | Steel | Steel | 2,750 | 1,433 | Yes | 4 | M5 × 0.8 mm | 00000000 | 000000 |

| 25 | 4 | 71 | 65 | 42 | Steel | Steel | 2,850 | 1,672 | Yes | 4 | M5 × 0.8 mm | 000000000 | 000000 |

| 28 | 4 | 80 | 70 | 45 | Steel | Steel | 4,150 | 2,557 | Yes | 4 | M6 × 1 mm | 00000000 | 000000 |

| 30 | 4 | 80 | 75 | 47 | Steel | Steel | 4,150 | 2,716 | Yes | 4 | M6 × 1 mm | 000000000 | 000000 |

| 37.4 | 4 | 100 | 90 | 60 | Steel | Steel | 6,900 | 5,637 | Yes | 4 | M8 × 1.25 mm | 00000000 | 000000 |

| 40 | 4 | 100 | 100 | 64 | Steel | Steel | 6,900 | 5,964 | Yes | 4 | M8 × 1.25 mm | 000000000 | 000000 |