About Shafts

More

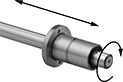

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Stainless steel shafts are more corrosion resistant than steel shafts but more difficult to machine. 303 stainless steel shafts have good corrosion resistance and are easier to machine than other types of stainless steel.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

For technical drawings and 3-D models, click on a part number.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Metric—1566 Carbon Steel | |||||||

|---|---|---|---|---|---|---|---|

16mm Dia. (Tolerance: -0.076mm to 0mm) | |||||||

| 200mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 000000 |

| 400mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 500mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,000mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,200mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,500mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 2,000mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

Metric—303 Stainless Steel | |||||||

16mm Dia. (Tolerance: -0.01mm to 0mm) | |||||||

| 100mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 200mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 400mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 600mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 800mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 1,000mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

Ball Splines and Bearings

Create a compact linear and rotary motion system for applications requiring complex, fast movements, such as robotics. The grooves on the ball splines transmit rotary power as ball bearings move smoothly and precisely along their length, even at high speeds.

Ball splines are alloy steel for high strength and wear resistance. They're hardened on the outside for additional wear resistance while the center is soft enough to absorb stress from shifting loads.

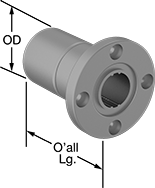

Bearings have a retaining ring groove, so they can be positioned in your system with a retaining ring (not included). Bearings with a keyway include a machine key for attaching your load. Flanged bearings have a surface with mounting holes for attaching your load.

For technical drawings and 3-D models, click on a part number.

Spline | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Dia. Tolerance, mm | Lg., mm | Lg. Tolerance, mm | Lg., mm | No. of | Root Dia., mm | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—52100 Alloy Steel | |||||||||||||

Splined on Both Ends | |||||||||||||

| 16 | -0.02 to 0 | 200 | -0.05 to 0.05 | 200 | 4 | 14.2 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 0000000 |

| 16 | -0.02 to 0 | 700 | -0.08 to 0.08 | 700 | 4 | 14.2 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

Material | Keyway | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | Includes | Dp., mm | Lg., mm | Wd., mm | Each | |

| 16 | 4 | 50 | 31 | Steel | Steel | 1,350 | 531 | Yes | Machine Key | 2 | 17.5 | 3.5 | 00000000 | 000000 |

Material | Mounting Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | Flange OD, mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | No. of | Thread Size | Each | |

| 16 | 4 | 50 | 50 | 31 | Steel | Steel | 1,350 | 531 | Yes | 4 | M4 × 0.7 mm | 000000000 | 0000000 |

Ball Screw/Splines and Bearings

From one compact system, transmit linear or rotary motion or both at once (sometimes called spiral motion). Because of these different motions, these ball screw/splines and bearings create efficient, fluid movements in complex automated applications, such as pick-and-place robots.

The ball bearings move smoothly and precisely, even at high speeds. They're powered independently, so you can drive one bearing at a time or both together to coordinate movements.

The ball screw/splines are hardened on the surface, so they stand up to repeated motion. They’re also hollow, so you can run electrical wiring, compressed air tubing, coolants, or lubricant through their center.

For technical drawings and 3-D models, click on a part number.

Spline | Thread | Ball Screw Bearing | Ball Spline Bearing | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | No. of | Lg. | Direction | ID, mm | Lg., mm | Root Dia., mm | OD, mm | Overall Lg., mm | Dynamic Load Cap., lbs. | Static Load Cap., lbs. | OD, mm | Overall Lg., mm | Dynamic Load Cap., lbs. | Static Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | Temp. Range, ° F | Each | |

Metric—1055 Carbon Steel | ||||||||||||||||||

16mm Dia. (Tolerance: -0.018mm to 0mm) | ||||||||||||||||||

| 500 mm | 6 | 360 mm | Right Hand | 11 | 500 | 15.15 | 32 | 40 | 870 | 1,610 | 31 | 50 | 1,590 | 2,830 | 277 | 5° to 176° | 0000000 | 000000000 |