About Shafts

More

About Casters and Wheels

More

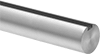

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use. 12L14 carbon steel shafts have a lead additive that makes them easier to machine than any other rotary shaft but also more prone to wear. Alloy steel shafts are good for high-stress applications. They are stronger than carbon steel and hardened for increased wear resistance; however, they are more difficult to machine.

Some steel shafts have a finish or coating to add corrosion or wear resistance. A black oxide finish gives the shaft mild corrosion resistance, so it should be used in dry environments. A chrome plating gives the shaft wear resistance and makes it more corrosion resistant than a shaft with a black oxide finish.

Stainless steel shafts are more corrosion resistant than steel shafts but more difficult to machine. 303 stainless steel shafts have good corrosion resistance and are easier to machine than other types of stainless steel. 316 stainless steel shafts are the most corrosion resistant stainless steel shaft.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

For technical drawings and 3-D models, click on a part number.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Finish Hardness Rating | Finish Hardness | Each | |

Inch—12L14 Carbon Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1/4" Dia. (Tolerance: -0.0002" to 0") | |||||||||

| 3" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 00000 |

| 4" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 0000 |

| 5" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 0000 |

| 6" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 0000000 | 0000 |

| 9" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 0000 |

| 12" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 0000000 | 0000 |

| 18" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 0000000 | 00000 |

| 24" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 0000000 | 00000 |

| 36" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 0000000 | 00000 |

| 48" | -0.01" to 0.01" | 0.0036" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 00000 |

Inch—Black-Oxide 1045 Carbon Steel | |||||||||

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 0000 |

| 18" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 0000 |

| 24" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 0000 |

| 36" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 00000 |

| 48" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 00000 |

| 60" | -0.0625" to 0.0625" | 0.003" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 000000 | 00000 |

Inch—Chrome-Plated 1045 Carbon Steel | |||||||||

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | -0.01" to 0.01" | 0.003" per ft. | Straight | Medium | Brinell 190 | Ultra Hard | Rockwell C68 | 0000000 | 0000 |

| 18" | -0.01" to 0.01" | 0.003" per ft. | Straight | Medium | Brinell 190 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 24" | -0.01" to 0.01" | 0.003" per ft. | Straight | Medium | Brinell 190 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 36" | -0.01" to 0.01" | 0.003" per ft. | Straight | Medium | Brinell 190 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 48" | -0.01" to 0.01" | 0.003" per ft. | Straight | Medium | Brinell 190 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

Inch—4140 Alloy Steel | |||||||||

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | __ | __ | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | __ | __ | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | __ | __ | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | __ | __ | 0000000 | 000000 |

Inch—303 Stainless Steel | |||||||||

1/4" Dia. (Tolerance: -0.0002" to 0") | |||||||||

| 3" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 4" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 5" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 6" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 0000 |

| 9" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 00000 |

| 12" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 18" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 24" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 36" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 48" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 00000 |

| 60" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 00000 |

| 72" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 00000 |

Inch—316 Stainless Steel | |||||||||

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 18" | -0.0625" to 0.0625" | 0.003" per ft. | Straight | Hard | Rockwell C21 | __ | __ | 0000000 | 00000 |

| 36" | -0.0625" to 0.0625" | 0.003" per ft. | Straight | Hard | Rockwell C21 | __ | __ | 0000000 | 00000 |

| 60" | -0.0625" to 0.0625" | 0.003" per ft. | Straight | Hard | Rockwell C21 | __ | __ | 0000000 | 000000 |

1/4" Dia. (Tolerance: -0.0002" to 0") | |||||||||

| 3" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 4" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 5" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 0000 |

| 6" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 9" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 00000000 | 00000 |

| 12" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 18" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 24" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

| 36" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | __ | __ | 0000000 | 00000 |

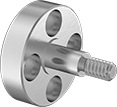

Flange-Mount Idler Rotary Shafts

Mount the flange to a machine or wall to support idler sprockets and pulleys in tensioning applications. They include washers and a nut to position your component and hold it in place.

For technical drawings and 3-D models, click on a part number.

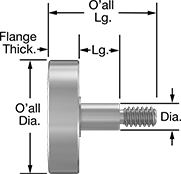

Overall | Thread | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

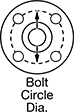

| Dia. | Lg. | Lg. | Dia. | Size | Lg. | Flange Thick. | Bolt Circle Dia. | No. of | Dia. | Edge Type | Hardness Rating | Hardness | Each | |

Inch—Zinc-Plated 1215 Carbon Steel | ||||||||||||||

| 1/4" | 3/8" | 1" | 1 1/16" | 10-24 | 11/32" | 9/32" | 23/32" | 4 | 5/32" | Straight | Not Rated | Not Rated | 0000000 | 000000 |

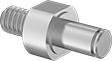

Thread-Mount Idler Rotary Shafts

Thread these shafts into a tapped hole to support idler sprockets and pulleys in tensioning applications.

Shafts with retaining ring grooves come with a retaining ring and spacers to position your component and hold it in place.

For technical drawings and 3-D models, click on a part number.

Overall | Thread | Groove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Dia. | Size | Lg. | Wd. | Dia. | End-to-Groove Lg. | Edge Type | Hardness Rating | Hardness | Each | |

Inch with Retaining Ring Grooves—Zinc-Plated 1215 Carbon Steel | |||||||||||||

| 1/4" | 3/8" | 1 1/16" | 1/2" | 1/4"-20 | 21/64" | 0.029" | 0.21" | 0.063" | Chamfered | Not Rated | Not Rated | 000000 | 00000 |

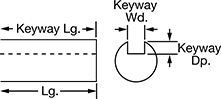

Keyed Rotary Shafts with Material Certification

In addition to diameter tolerances that are twice as tight as standard keyed shafts, these shafts include a traceable lot number and test report. Use them with machine keys (not included) to transmit torque to gears, sprockets, and other power transmission components. Shafts are 1045 carbon steel, a general purpose shafting material that balances high strength and good machinability. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to meet tight diameter and straightness tolerances.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||||

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||||||

| 3" | -0.005" to 0.005" | 3" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 000000 |

| 6" | -0.005" to 0.005" | 6" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 00000 |

| 9" | -0.005" to 0.005" | 9" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 00000 |

| 12" | -0.005" to 0.005" | 12" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 00000 |

| 24" | -0.005" to 0.005" | 24" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 00000 |

| 36" | -0.005" to 0.005" | 36" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 00000 |

| 48" | -0.005" to 0.005" | 48" | 0.094" | 0.047" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 000000 | 000000 |

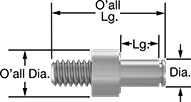

Threaded Rotary Shafts

Attach threaded accessories, such as mixer propellers and fan blades, to the end of these shafts. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances. Made of carbon steel, these shafts balance high strength and good machinability, making them ideal for general purpose use.

For technical drawings and 3-D models, click on a part number.

Threaded End | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Size | Lg. | Step Lg. | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1117 Carbon Steel | ||||||||||

1/4" Dia. (Tolerance: -0.0002" to 0") | ||||||||||

| 6" | -0.125" to 0.125" | 10-32 | 3/8" | 7/16" | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 000000 |

| 6" | -0.125" to 0.125" | 1/4"-20 | 1/2" | __ | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 00000 |

| 12" | -0.125" to 0.125" | 10-32 | 3/8" | 7/16" | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 00000 |

| 12" | -0.125" to 0.125" | 1/4"-20 | 1/2" | __ | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 00000 |

| 24" | -0.125" to 0.125" | 10-32 | 3/8" | 7/16" | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 00000 |

| 24" | -0.125" to 0.125" | 1/4"-20 | 1/2" | __ | 0.0048" per ft. | Chamfered | Medium | Rockwell B75 | 0000000 | 00000 |

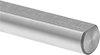

D-Profile Rotary Shafts

A flat surface area allows set screws to dig into the shaft for securely mounting gears, sprockets, and bearings. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances.

1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use. They are stronger than aluminum and stainless steel shafts but not as corrosion resistant. 303 stainless steel shafts are more corrosion resistant than steel shafts but also more difficult to machine.

For technical drawings and 3-D models, click on a part number.

| Lg. | Lg. Tolerance | Flat Wd. | D-Profile Lg. | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1/4" Dia. (Tolerance: -0.003" to 0") | |||||||||

| 6" | -0.0625" to 0.0625" | 1/8" | 6" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 00000000 | 00000 |

| 12" | -0.0625" to 0.0625" | 1/8" | 12" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 00000000 | 00000 |

| 24" | -0.0625" to 0.0625" | 1/8" | 24" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 00000000 | 00000 |

| 36" | -0.0625" to 0.0625" | 1/8" | 36" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 00000000 | 00000 |

| 48" | -0.0625" to 0.0625" | 1/8" | 48" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 00000000 | 00000 |

Inch—303 Stainless Steel | |||||||||

1/4" Dia. (Tolerance: -0.003" to 0") | |||||||||

| 6" | -0.0625" to 0.0625" | 1/8" | 6" | 0.012" per ft. | Chamfered | Medium | Rockwell B83 | 00000000 | 00000 |

| 12" | -0.0625" to 0.0625" | 1/8" | 12" | 0.012" per ft. | Chamfered | Medium | Rockwell B83 | 00000000 | 00000 |

| 24" | -0.0625" to 0.0625" | 1/8" | 24" | 0.012" per ft. | Chamfered | Medium | Rockwell B83 | 00000000 | 00000 |

| 36" | -0.0625" to 0.0625" | 1/8" | 36" | 0.012" per ft. | Chamfered | Medium | Rockwell B83 | 00000000 | 00000 |

| 48" | -0.0625" to 0.0625" | 1/8" | 48" | 0.012" per ft. | Chamfered | Medium | Rockwell B83 | 00000000 | 00000 |

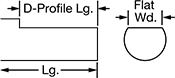

Tapped D-Profile Rotary Shafts

Connect these internally threaded shafts directly to threaded components, or use a fastener to secure. They have a flat surface area that allows set screws to dig into the shaft for securely mounting gears, sprockets, and bearings. Shafts are 1045 carbon steel, a general purpose shafting material that balances high strength and good machinability. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to meet tight diameter and straightness tolerances.

For technical drawings and 3-D models, click on a part number.

Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Flat Wd. | D-Profile Lg. | Size | Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||||

1/4" Dia. (Tolerance: -0.003" to 0") | |||||||||||

| 6" | 1/8" | 6" | 5-40 | 0.375" | -0.0625" to 0.0625" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 000000 | 000000 |

| 12" | 1/8" | 12" | 5-40 | 0.375" | -0.0625" to 0.0625" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 000000 | 00000 |

| 24" | 1/8" | 24" | 5-40 | 0.375" | -0.0625" to 0.0625" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 0000000 | 00000 |

| 48" | 1/8" | 48" | 5-40 | 0.375" | -0.0625" to 0.0625" | 0.012" per ft. | Chamfered | Medium | Rockwell B90 | 0000000 | 00000 |

Rotary Shafts with Retaining Ring Grooves

Clip retaining rings into the grooves to separate and position gears, sprockets, and bearings. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances. Made of 303 stainless steel, they are more corrosion resistant than steel shafts but also more difficult to machine.

For technical drawings and 3-D models, click on a part number.

Groove | No. of Grooves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Wd. | Dia. | End-to-Groove Lg. | Groove-to-Groove Lg. | First End | Second End | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—303 Stainless Steel | |||||||||||||

1/4" Dia. (Tolerance: -0.0002" to 0") | |||||||||||||

| 3" | -0.01" to 0.01" | 0.029" | 0.21" | 0.063" | 0.25" | 5 | 2 | 0.0008" per in. | Chamfered | Medium | Rockwell B83 | 000000 | 00000 |

| 6" | -0.01" to 0.01" | 0.029" | 0.21" | 0.063" | 0.25" | 5 | 2 | 0.0008" per in. | Chamfered | Medium | Rockwell B83 | 000000 | 0000 |

| 12" | -0.01" to 0.01" | 0.029" | 0.21" | 0.063" | 0.25" | 5 | 2 | 0.0008" per in. | Chamfered | Medium | Rockwell B83 | 000000 | 00000 |

Undersized Rotary Shafts

The diameter of these shafts is slightly smaller than listed, so precision ball bearings (ABEC-3 and above) slide on without any tools. This saves you from having to use a bearing heater or mechanical press, which can cause damage. These rotary shafts are also known as drive shafts because they’re frequently used with a motor to drive power transmission applications. All are turned, ground, and polished to tight diameter and straightness tolerances. This allows them to evenly distribute loads, reduce vibration, and improve accuracy and stability. They’re stainless steel, so they resist corrosion. All have chamfered edges to remove sharp corners, reducing damage to bearings, housings, and other components during installation.

For technical drawings and 3-D models, click on a part number.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—303 Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

1/4" Dia. (Tolerance: -0.0005" to -0.0003") | |||||||

| 6" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 12" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | 0000000 | 0000 |

| 24" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 36" | -0.01" to 0.01" | 0.0048" per ft. | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

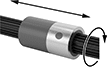

Sleeve Splines and Bearings

Often used in wet and dirty environments, these sleeve splines and bearings create a compact linear and rotary motion system. The grooves on the splines transmit rotary power as the sleeve bearing moves freely along their length. Sleeve bearings don't have moving parts that can be damaged from dirt and debris. And they don't need to be lubricated, making them overall lower maintenance than ball bearings.

Splines are PTFE coated to reduce friction, so bearings slide smoothly and last longer. They’re stainless steel, so they won’t rust.

Bearings are plastic with a bronze shell, so they won't rust. Threaded bearings allow you to mount your load directly to the bearing. Anti-backlash bearings minimize the space (play) between the bearing and spline for more accurate, repeatable positioning.

Flanges work with threaded bearings to give you a surface with mounting holes to attach your load.

For technical drawings and 3-D models, click on a part number.

Spline | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | No. of | Lg. | Lg. Tolerance | Root Dia. | Material | Edge Type | Hardness Rating | Hardness | Each | |

1/4" Dia. (Tolerance: -0.002" to 0.002") | ||||||||||

| 12" | 14 | 12" | 0" to 0.25" | 0.202" | PTFE-Coated 304 Stainless Steel | Straight | Medium | Rockwell B70 | 0000000 | 000000 |

| 24" | 14 | 24" | 0" to 0.25" | 0.202" | PTFE-Coated 304 Stainless Steel | Straight | Medium | Rockwell B70 | 0000000 | 000000 |

| 36" | 14 | 36" | 0" to 0.25" | 0.202" | PTFE-Coated 304 Stainless Steel | Straight | Medium | Rockwell B70 | 0000000 | 000000 |

| For Spline Diameter | Number of Splines | OD | Overall Length | Dynamic Load Capacity, lbs. | Static Load Capacity, lbs. | Max. Dynamic Torque | Max. Static Torque | Bearing Material | Shell Material | Each | |

| 1/4" | 14 | 1/2" | 3/4" | 5 | 5 | Not Rated | Not Rated | Plastic | Bronze | 0000000 | 000000 |

| For Spline Diameter | Number of Splines | OD | Overall Length | Thread Size | Dynamic Load Capacity, lbs. | Static Load Capacity, lbs. | Max. Dynamic Torque | Max. Static Torque | Bearing Material | Shell Material | Each | |

| 1/4" | 14 | 1/2" | 3/4" | 7/16"-20 | 5 | 5 | Not Rated | Not Rated | Plastic | Bronze | 0000000 | 000000 |

| For Spline Diameter | Number of Splines | OD | Overall Length | Thread Size | Dynamic Load Capacity, lbs. | Static Load Capacity, lbs. | Max. Dynamic Torque | Max. Static Torque | Bearing Material | Shell Material | Each | |

| 1/4" | 14 | 1/2" | 3/4" | 7/16"-20 | 5 | 5 | Not Rated | Not Rated | Plastic | Bronze | 0000000 | 000000 |

Flange | Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thick. | OD | Bolt Circle Dia. | Material | No. of | Dia. | Mounting Fasteners Included | Each | |

| 7/16"-20 | 1/4" | 1 3/16" | 7/8" | Anodized Aluminum | 4 | 0.144" | No | 0000000 | 000000 |