About Composites

More

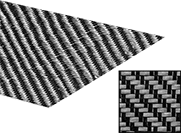

Composite Fabrics

Use these resin-free fabrics to reinforce or repair existing composites as well as create new composites. Mold custom-shaped composite parts by layering your choice of fabric with an epoxy. The epoxy (sold separately) is a two-part resin that begins to harden in 15 hours and reaches full strength in 4 days. Finished composite pieces withstand temperatures up to 250° or 350° F.

Fabrics with a plain, twill, or triaxial weave have fibers that are woven in alternating directions for uniform strength and rigidity in all directions. Easier to machine than fabrics with a unidirectional weave, their woven pattern holds the fibers together to limit splintering. Twill-weave fabrics are stronger than plain-weave fabrics. They’re also more flexible, making them easier to manipulate into complex shapes. They will not, however, retain their shape as well as plain-weave fabrics.

Kevlar fabrics are a super-tough material that offers excellent wear and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

Cut-Resistant Kevlar Webbing

This webbing resists abrasion caused by sharp corners and edges. Use it to create straps, belts, and tie downs. It has a finished end with a locking stitch that won't unravel. To prevent fraying after a new cut, fold and sew or use a finishing tip.

Note: Breaking strength is the force at which new webbing will break, and should never be considered the work load limit.

Warning: Never use for lifting applications.