Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

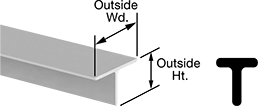

Multipurpose 6061 Aluminum T-Bars

- Yield Strength: 35,000 psi

- Hardness: Brinell 80 (Soft)

- Temper: T6

- Fabrication: Extruded

- Specifications Met: ASTM B221

The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

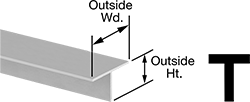

Outside | Corner Shape | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Heat Treatment | Temperature Range, °F | Outside | Inside | Leg Edge Shape | Straightness Tolerance | 2 ft. Lg. | 4 ft. Lg. | 8 ft. Lg. | |

0.05" Wall Thick. (-0.006" to 0.006" Tolerance) | |||||||||||||

| 1/2" | -0.014" to 0.014" | 5/8" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

0.062" Wall Thick. (-0.01" to 0.01" Tolerance) | |||||||||||||

| 3/4" | -0.014" to 0.014" | 1 1/4" | -0.024" to 0.024" | Hardened | -320° to 300° | Round | Round | Round | 0.013" per ft. | 0000000 | |||

| 1" | -0.014" to 0.014" | 1 1/4" | -0.024" to 0.024" | Hardened | -320° to 300° | Round | Round | Round | 0.013" per ft. | 0000000 | |||

| 2" | -0.014" to 0.014" | 1 1/4" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

1/8" Wall Thick. (-0.007" to 0.007" Tolerance) | |||||||||||||

| 1/4" | -0.014" to 0.014" | 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1/2" | -0.014" to 0.014" | 1" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 3/4" | -0.014" to 0.014" | 3/4" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 3/4" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 7/8" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Round | Round | Round | 0.013" per ft. | 0000000 | |||

| 1" | -0.014" to 0.014" | 1" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1" | -0.014" to 0.014" | 2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/4" | -0.014" to 0.014" | 2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/2" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/2" | -0.014" to 0.014" | 2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/2" | -0.014" to 0.014" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

0.188" Wall Thick. (-0.007" to 0.007" Tolerance) | |||||||||||||

| 1" | -0.014" to 0.014" | 1" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1" | -0.014" to 0.014" | 2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/2" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

| 1 1/2" | -0.014" to 0.014" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

1/4" Wall Thick. (-0.01" to 0.01" Tolerance) | |||||||||||||

| 1 1/2" | -0.014" to 0.014" | 1 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | Square | Square | Square | 0.013" per ft. | 0000000 | |||

High-Strength 2024 Aluminum T-Bars

- Yield Strength: 42,000 psi

- Hardness: Brinell 120 (Medium)

- Temper: T3511

- Fabrication: Extruded

- Specifications Met: ASTM B221, SAE AMS-QQ-A-200/3

While 2024 aluminum was initially designed for structural components in aircraft, it's now widely used when a high strength-to-weight ratio is needed. It offers similar performance to 7075 aluminum, but it’s not as strong.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

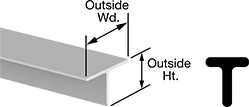

Outside | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Heat Treatment | Temperature Range, °F | Straightness Tolerance | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

1/16" Wall Thick. (-0.007" to 0.007" Tolerance) | ||||||||||

| 3/4" | -0.024" to 0.024" | 1 1/2" | -0.014" to 0.014" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 1" | -0.024" to 0.024" | 1 3/8" | -0.014" to 0.014" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

1/8" Wall Thick. (-0.007" to 0.007" Tolerance) | ||||||||||

| 1" | -0.024" to 0.024" | 2" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 1 1/2" | -0.024" to 0.024" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 2" | -0.024" to 0.024" | 2 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 2 1/2" | -0.024" to 0.024" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

3/16" Wall Thick. (-0.007" to 0.007" Tolerance) | ||||||||||

| 2" | -0.024" to 0.024" | 2 1/2" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 2" | -0.024" to 0.024" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

| 2 1/2" | -0.024" to 0.024" | 3" | -0.024" to 0.024" | Hardened | -320° to 300° | 0.050" per ft. | 0000000 | |||

Ceiling Tile Frames

Use these components to design your own frame to support ceiling tiles.

Aluminum frames are corrosion resistant and withstand higher humidity than steel.

For technical drawings and 3-D models, click on a part number.

Ceiling Tile Clips

Secure ceiling tiles or join ceiling tile frame components.

Clips for ceiling tiles keep ceiling tiles in place. Those for 1/16"-5/8" ceiling tiles are best for entryways and other drafty areas.

Clips for ceiling tile frames join ceiling tile frames and molding. Tee clips join molding to main beams and cross tees. Those for 9/16”-15/16” ceiling tile frames help you comply with ICC-ES seismic requirements when properly installed.

For technical drawings and 3-D models, click on a part number.

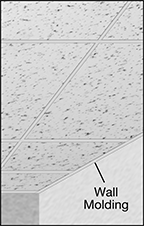

Ceiling Tile Wall Molding

Secure tile frames to the wall.

Aluminum molding is corrosion resistant and withstands higher humidity than steel.

For technical drawings and 3-D models, click on a part number.