Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

About Rod Ends

More

High-Strength 7075 Aluminum Rods and Discs

Originally developed for aircraft frames, uses for 7075 aluminum now include keys, gears, and other high-stress parts. It is often used as a replacement for 2024 aluminum because it’s stronger and provides similar performance in all other aspects.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 73,000 psi

- Hardness: Brinell 150 (Medium)

- Temper:

3/8" to 5/8" dia.: T6

All other sizes: T651 - Fabrication: Cold Drawn

- Specifications Met: ASTM B211, SAE AMS-QQ-A-225/9

| Dia. | Dia. Tolerance | Heat Treatment | Temperature Range, °F | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

| 3/8" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 1/2" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 5/8" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 3/4" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 7/8" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 1" | -0.002" to 0.002" | Hardened | -320° to 210° | 00000000 | |||||

| 1 1/8" | -0.003" to 0.003" | Hardened | -320° to 210° | 00000000 | |||||

| 1 1/4" | -0.003" to 0.003" | Hardened | -320° to 210° | 00000000 | |||||

| 1 3/8" | -0.003" to 0.003" | Hardened | -320° to 210° | 00000000 | |||||

| 1 1/2" | -0.003" to 0.003" | Hardened | -320° to 210° | 00000000 | |||||

| 1 5/8" | -0.004" to 0.004" | Hardened | -320° to 210° | 00000000 | |||||

| 1 3/4" | -0.004" to 0.004" | Hardened | -320° to 210° | 00000000 | |||||

| 1 7/8" | -0.004" to 0.004" | Hardened | -320° to 210° | 00000000 | |||||

| 2" | -0.004" to 0.004" | Hardened | -320° to 210° | 00000000 | |||||

| 2 1/8" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 2 1/4" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 2 3/8" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 2 1/2" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 2 5/8" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 2 3/4" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 3" | -0.006" to 0.006" | Hardened | -320° to 210° | 00000000 | |||||

| 3 1/4" | -0.008" to 0.008" | Hardened | -320° to 210° | 00000000 | |||||

| 3 1/2" | -0.012" to 0.012" | Hardened | -320° to 210° | 00000000 | |||||

| 3 3/4" | -0.012" to 0.012" | Hardened | -320° to 210° | 00000000 | |||||

| 4" | -0.012" to 0.012" | Hardened | -320° to 210° | 00000000 | |||||

| 4 1/2" | -0.012" to 0.012" | Hardened | -320° to 210° | 00000000 | |||||

| 5" | -0.012" to 0.012" | Hardened | -320° to 210° | 00000000 | |||||

| 6" | -0.016" to 0.016" | Hardened | -320° to 210° | 00000000 |

- Yield Strength: 73,000 psi

- Hardness: Brinell 150 (Medium)

- Temper: T651

- Fabrication: Cold Drawn

- Specifications Met: ASTM B211

| Dia. | Dia. Tolerance | Heat Treatment | Temperature Range, °F | 1/4" Lg. | 1/2" Lg. | 1" Lg. | 3" Lg. | |

| 2" | -0.004" to 0.004" | Hardened | -320° to 210° | 0000000 | ||||

| 2 1/4" | -0.006" to 0.006" | Hardened | -320° to 210° | 0000000 | ||||

| 2 1/2" | -0.006" to 0.006" | Hardened | -320° to 210° | 0000000 | ||||

| 2 3/4" | -0.006" to 0.006" | Hardened | -320° to 210° | 0000000 | ||||

| 3" | -0.008" to 0.008" | Hardened | -320° to 210° | 0000000 | ||||

| 3 1/4" | -0.008" to 0.008" | Hardened | -320° to 210° | 0000000 | ||||

| 3 1/2" | -0.012" to 0.012" | Hardened | -320° to 210° | 0000000 | ||||

| 4" | -0.012" to 0.012" | Hardened | -320° to 210° | 0000000 | ||||

| 4 1/2" | -0.012" to 0.012" | Hardened | -320° to 210° | 0000000 | ||||

| 5" | -0.012" to 0.012" | Hardened | -320° to 210° | 0000000 | ||||

| 5 1/2" | -0.020" to 0.020" | Hardened | -320° to 210° | 0000000 | ||||

| 6" | -0.020" to 0.020" | Hardened | -320° to 210° | 0000000 | ||||

| 7" | -0.025" to 0.025" | Hardened | -320° to 210° | 0000000 | ||||

| 8" | -0.030" to 0.030" | Hardened | -320° to 210° | 0000000 |

Tight-Tolerance High-Strength 7075 Aluminum Rods

- Yield Strength: 73,000 psi

- Hardness: Brinell 150 (Medium)

- Temper: T6

- Fabrication: Cold Worked

- Specifications Met: ASTM B211

Ready for turning in a lathe, these rods are precision ground and held to a strict straightness tolerance. Originally developed for aircraft frames, uses for 7075 aluminum now include keys, gears, and other high-stress parts. It is often used as a replacement for 2024 aluminum because it’s stronger and provides similar performance in all other aspects.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Heat Treatment | Temperature Range, °F | Straightness Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

| 3/32" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1/8" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 3/16" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1/4" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 5/16" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 3/8" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 7/16" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1/2" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 9/16" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 5/8" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 11/16" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 3/4" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 7/8" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1 1/4" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 1 1/2" | -0.0005" to 0.0000" | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 4mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 5mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 6mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 8mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 10mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 12mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 15mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 20mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 25mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 30mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 | |||||

| 40mm | -0.0127mm to 0.0000mm | Hardened | -320° to 210° | 0.005" per ft. | 0000000 |

High-Strength 7075 Aluminum Hex Bars

- Yield Strength: 56,000 psi

- Hardness: Brinell 125 (Medium)

- Temper: T7351

- Fabrication: Cold Drawn

- Specifications Met: ASTM B211, SAE AMS-QQ-A-225/9

Originally developed for aircraft frames, uses for 7075 aluminum now include shafts, gears, and other high-stress parts. It is often used as a replacement for 2024 aluminum because it’s stronger and provides similar performance in all other aspects.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

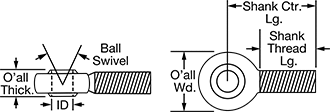

Lightweight Corrosion-Resistant Ball Joint Rod Ends

These anodized aluminum rod ends are lighter than stainless steel rod ends and have good corrosion resistance. A PTFE liner allows smooth ball rotation and eliminates the need for lubrication.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| 10-32 | 3/16" | 13° | 5/8" | 5/16" | 1 1/4" | 3/4" | 1,350 | Anodized 7075 Aluminum | 00000000 | 000000 | |

| 1/4"-28 | 1/4" | 16° | 3/4" | 3/8" | 1 9/16" | 1" | 2,450 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 5/16"-24 | 5/16" | 14° | 7/8" | 7/16" | 1 7/8" | 1 1/4" | 2,850 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 3/8"-24 | 3/8" | 12° | 1" | 1/2" | 1 15/16" | 1 1/4" | 4,200 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 7/16"-20 | 7/16" | 14° | 1 1/8" | 9/16" | 2 1/8" | 1 3/8" | 4,500 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 1/2"-20 | 1/2" | 12° | 1 5/16" | 5/8" | 2 7/16" | 1 1/2" | 7,650 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 5/8"-18 | 5/8" | 16° | 1 1/2" | 3/4" | 2 5/8" | 1 5/8" | 8,500 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 3/4"-16 | 3/4" | 14° | 1 3/4" | 7/8" | 2 7/8" | 1 3/4" | 13,300 | Anodized 7075 Aluminum | 00000000 | 00000 |

Internally Threaded Lightweight Corrosion-Resistant Ball Joint Rod Ends

These anodized aluminum rod ends are lighter than stainless steel rod ends and have good corrosion resistance. A PTFE liner allows smooth ball rotation and eliminates the need for lubrication.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| 10-32 | 3/16" | 13° | 5/8" | 5/16" | 1 1/16" | 1/2" | 1,350 | Anodized 7075 Aluminum | 00000000 | 000000 | |

| 1/4"-28 | 1/4" | 16° | 3/4" | 3/8" | 1 5/16" | 11/16" | 2,550 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 5/16"-24 | 5/16" | 14° | 7/8" | 7/16" | 1 3/8" | 11/16" | 2,850 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 3/8"-24 | 3/8" | 12° | 1" | 1/2" | 1 5/8" | 13/16" | 3,950 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 7/16"-20 | 7/16" | 14° | 1 1/8" | 9/16" | 1 13/16" | 15/16" | 4,500 | Anodized 7075 Aluminum | Right Hand | 000000000 | 00000 |

| 1/2"-20 | 1/2" | 12° | 1 5/16" | 5/8" | 2 1/8" | 1 1/16" | 7,000 | Anodized 7075 Aluminum | 00000000 | 00000 | |

| 5/8"-18 | 5/8" | 16° | 1 1/2" | 3/4" | 2 1/2" | 1 3/8" | 8,500 | Anodized 7075 Aluminum | Right Hand | 000000000 | 00000 |

| 3/4"-16 | 3/4" | 14° | 1 3/4" | 7/8" | 2 7/8" | 1 9/16" | 13,300 | Anodized 7075 Aluminum | 00000000 | 00000 |