Bend-and-Stay Air Nozzles

Nozzles are attached to a flexible hose that bends and holds its shape until you reposition it. They conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Hose Material | Specifications Met | Each | ||

| A | 1/8 | NPT | Male | Not Rated | Not Rated | Not Rated | 7/16" | 9" | 30 | Steel | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

| B | 1/8 | NPT | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1/2" | 6 9/16" | 150 | Brass | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 1/8 | NPT | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1/2" | 12 9/16" | 150 | Brass | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| C | 1/8 | NPT | Male | 14 cfm @ 100 psi | 100° | 85 dBA @ 80 psi | 1/4" | 7 1/2" | 90 | Nylon Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| D | 1/4 | NPT | Male | 31 cfm @ 100 psi | 160° | 89 dBA @ 80 psi | 3/4" | 12 1/4" | 150 | Brass | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

Wide-Airflow Bend-and-Stay Air Nozzles

The flat shape distributes air over a wider area than focused-airflow nozzles. These nozzles are attached to a flexible hose that bends and holds its shape until you reposition it. All conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure and OSHA 29 CFR 1910.95 requirements for noise.

316 stainless steel nozzles are more corrosion resistant than zinc nozzles.

For technical drawings and 3-D models, click on a part number.

Air Inlet | Tip | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Hose Material | Specifications Met | Each | |

316 Stainless Steel | |||||||||||||

| 1/4 | NPT | Male | 12 cfm @ 100 psi | 140° | 75 dBA @ 80 psi | 1" | 3/8" | 6 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 0000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 7 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 13 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 19 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

Zinc | |||||||||||||

| 1/4 | NPT | Male | 12 cfm @ 100 psi | 140° | 75 dBA @ 80 psi | 1" | 3/8" | 25" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 14 cfm @ 100 psi | 140° | 75 dBA @ 80 psi | 1" | 3/8" | 13 11/16" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 000000 |

| 1/4 | NPT | Male | 21 cfm @ 100 psi | 140° | 85 dBA @ 80 psi | 1" | 3/8" | 25" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 7 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 13 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 19 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 26 cfm @ 100 psi | 140° | 80 dBA @ 80 psi | 2" | 3/8" | 25 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 45 cfm @ 100 psi | 140° | 85 dBA @ 80 psi | 2" | 1/2" | 7 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 45 cfm @ 100 psi | 140° | 85 dBA @ 80 psi | 2" | 1/2" | 13 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 45 cfm @ 100 psi | 140° | 85 dBA @ 80 psi | 2" | 1/2" | 19 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| 1/4 | NPT | Male | 45 cfm @ 100 psi | 140° | 85 dBA @ 80 psi | 2" | 1/2" | 37 3/4" | 250 | PVC Plastic | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

Magnet-Mount Bend-and-Stay Air Nozzles

The magnetic base with an attached flexible hose mounts to your work surface. Bend the hose to position the nozzle and keep it in place. Use the control valve on the base to adjust airflow.

Zinc nozzle meets OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure and OSHA 29 CFR 1910.95 requirements for noise.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Hoses | Hose Connection Type | For Hose ID | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Magnetic Pull, lbs. | Max. Inlet Pressure, psi | Material | Each | |

Acetal Plastic Nozzle | |||||||||||||

| 1 | Barbed | 1/4" | Male | 3 cfm @ 50 psi | 150 | Not Rated | 5/8" | 11 3/8" | 38 | 60 | Acetal Plastic | 0000000 | 000000 |

| 2 | Barbed | 1/4" | Male | 6 cfm @ 50 psi | 150 | Not Rated | 5/8" | 11 3/8" | 38 | 60 | Acetal Plastic | 0000000 | 00000 |

Air Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Hoses | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Magnetic Pull, lbs. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | |

Zinc Nozzle | ||||||||||||||

| 1 | 1/4 | NPT | Female | 16 cfm @ 100 psi | 140 | 74 dBA @ 80 psi | 3/4" | 15 11/16" | 100 | 150 | Zinc | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 0000000 |

Create-Your-Own Bend-and-Stay Air Nozzles

Choose a base, hose, and air nozzle for a custom setup. Bend the flexible hose to position the nozzle and keep it in place.

PVC hose has a copper core that lets you bend it into nearly any position. It will hold its position even as high-pressure air flows through it. Stainless steel hose has extra durability to withstand frequent repositioning.

Bases are magnetic, so they mount to metal work surfaces. 360° swivel bases let you set the air outlet at any angle.

Air nozzles that meet OSHA 29 CFR 1910.242 adhere to requirements for maximum air outlet pressure. Some also meet OSHA 29 CFR 1910.95 requirements for noise. Wide-airflow air nozzles have a flat shape that distributes air over a wider area than nozzles with a focused airflow.

| Lg. | Each | |

1/8 NPT Female Outlet × 1/4 NPT Male Inlet | ||

|---|---|---|

PVC Plastic | ||

| 6" | 0000000 | 000000 |

| 12" | 0000000 | 00000 |

| 18" | 0000000 | 00000 |

| 24" | 0000000 | 00000 |

| 30" | 0000000 | 00000 |

| 36" | 0000000 | 000000 |

1/4 NPT Male Outlet × 1/4 NPT Male Inlet | ||

PVC Plastic | ||

| 6" | 0000000 | 00000 |

| 12" | 0000000 | 00000 |

| 18" | 0000000 | 00000 |

| 24" | 0000000 | 00000 |

| 30" | 0000000 | 00000 |

| 36" | 0000000 | 000000 |

1/4 NPT Female Outlet × 1/4 NPT Male Inlet | ||

Rubber | ||

| 6" | 0000000 | 00000 |

| 12" | 0000000 | 00000 |

| 18" | 0000000 | 00000 |

| 24" | 0000000 | 00000 |

| 30" | 0000000 | 00000 |

| 36" | 0000000 | 00000 |

304 Stainless Steel | ||

| 7" | 0000000 | 000000 |

| 11" | 0000000 | 000000 |

| 15" | 0000000 | 000000 |

| 19" | 0000000 | 000000 |

| Air Consumption | Max. Temp., °F | Volume | Tip OD | Overall Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/8 NPT Male Inlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|

ABS Plastic | |||||||||

| A | 21 cfm @ 75 psi | 120° | 50 dBA @ 80 psi | 15/16" | 2 3/16" | 100 | __ | 0000000 | 000000 |

PEEK Plastic | |||||||||

| B | 12 cfm @ 100 psi | 500° | 80 dBA @ 80 psi | 5/16" | 1 1/4" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

Zinc | |||||||||

| C | 15 cfm @ 100 psi | 158° | 81 dBA @ 80 psi | 5/16" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| D | 3 cfm @ 100 psi | 1000° | 58 dBA @ 80 psi | 3/16" | 27/32" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

| D | 5 cfm @ 100 psi | 1000° | 68 dBA @ 80 psi | 7/32" | 31/32" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

| D | 10 cfm @ 100 psi | 752° | 78 dBA @ 80 psi | 5/16" | 1 5/16" | 145 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| D | 10 cfm @ 100 psi | 1000° | 75 dBA @ 80 psi | 1/4" | 1 1/16" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

17-4 PH Stainless Steel | |||||||||

| C | 15 cfm @ 100 psi | 752° | 81 dBA @ 80 psi | 5/16" | 1 1/2" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 000000 |

1/4 NPT Male Inlet | |||||||||

ABS Plastic | |||||||||

| A | 21 cfm @ 75 psi | 120° | 50 dBA @ 80 psi | 15/16" | 2 3/16" | 100 | __ | 0000000 | 00000 |

Aluminum | |||||||||

| F | 15 cfm @ 100 psi | 302° | 81 dBA @ 80 psi | 3/4" | 2 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| D | 27 cfm @ 100 psi | 752° | 88 dBA @ 80 psi | 5/16" | 1 17/32" | 145 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

1/4 NPT Female Inlet | |||||||||

Zinc | |||||||||

| G | 18 cfm @ 100 psi | 250° | 74 dBA @ 80 psi | 3/4" | 1 3/4" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 00000 |

Brass | |||||||||

| H | 21 cfm @ 100 psi | 400° | 80 dBA @ 80 psi | 1/2" | 1 7/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 00000 |

18-8 Stainless Steel | |||||||||

| H | 21 cfm @ 100 psi | 800° | 80 dBA @ 80 psi | 1/2" | 1 7/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| J | 41 cfm @ 100 psi | 752° | 90 dBA @ 80 psi | 19/32" | 31/32" | 145 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

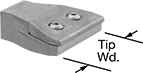

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | Overall Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/8 NPT Male Inlet | ||||||||||

316L Stainless Steel | ||||||||||

| A | 17 cfm @ 100 psi | 750° | 84 dBA @ 80 psi | 15/16" | 3/16" | 2 1/4" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000000 |

1/4 NPT Male Inlet | ||||||||||

Nylon Plastic | ||||||||||

| B | 24 cfm @ 100 psi | 350° | 84 dBA @ 80 psi | 1 7/8" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

| B | 58 cfm @ 100 psi | 350° | 90 dBA @ 80 psi | 2 3/4" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

ABS Plastic | ||||||||||

| C | 17 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 100 | __ | 0000000 | 00000 |

| C | 43 cfm @ 90 psi | 170° | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

316 Stainless Steel | ||||||||||

| C | 22 cfm @ 100 psi | 500° | 82 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 150 | OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

| C | 43 cfm @ 90 psi | 500° | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 150 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

316L Stainless Steel | ||||||||||

| A | 46 cfm @ 100 psi | 750° | 89 dBA @ 80 psi | 2 7/16" | 3/16" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/4 NPT Female Inlet | ||||||||||

ABS Plastic | ||||||||||

| C | 30 cfm @ 90 psi | 170° | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

| C | 43 cfm @ 90 psi | 170° | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

Zinc | ||||||||||

| E | 26 cfm @ 100 psi | 250° | 75 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 000000 |

| E | 37 cfm @ 80 psi | 250° | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

316 Stainless Steel | ||||||||||

| E | 22 cfm @ 80 psi | 1000° | 77 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

| E | 37 cfm @ 80 psi | 1000° | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |