About Sound Levels

Measured in decibels (dB), volume ratings indicate how much noise equipment makes. Some common volume levels include a whisper @ 20 dB, a refrigerator @ 40 dB, a conversation @ 60 dB, and a light machine shop @ 90 dB. OSHA recommends hearing protection for exposure to 80 dB and greater.

Air Nozzles

These nozzles are engineered for the most efficient air consumption.

Nozzles that meet OSHA 29 CFR 1910.242 conform to requirements for maximum air outlet pressure. Nozzles that meet OSHA 29 CFR 1910.95 conform to requirements for noise.

For technical drawings and 3-D models, click on a part number.

| Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/8 NPT Male Inlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|

ABS Plastic | |||||||||

| A | 21 cfm @ 75 psi | 120° | 50 dBA @ 80 psi | 15/16" | 2 3/16" | 100 | __ | 0000000 | 000000 |

PEEK Plastic | |||||||||

| B | 12 cfm @ 100 psi | 500° | 80 dBA @ 80 psi | 5/16" | 1 1/4" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

Zinc | |||||||||

| C | 15 cfm @ 100 psi | 158° | 81 dBA @ 80 psi | 5/16" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| D | 3 cfm @ 100 psi | 1000° | 58 dBA @ 80 psi | 3/16" | 27/32" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

| D | 5 cfm @ 100 psi | 1000° | 68 dBA @ 80 psi | 7/32" | 31/32" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

| D | 10 cfm @ 100 psi | 752° | 78 dBA @ 80 psi | 5/16" | 1 5/16" | 145 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 000000000 | 000000 |

| D | 10 cfm @ 100 psi | 1000° | 75 dBA @ 80 psi | 1/4" | 1 1/16" | 250 | OSHA Compliant 29 CFR 1910.242 | 000000000 | 00000 |

17-4 PH Stainless Steel | |||||||||

| C | 15 cfm @ 100 psi | 752° | 81 dBA @ 80 psi | 5/16" | 1 1/2" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 000000 |

1/8 NPT Female Inlet | |||||||||

Zinc | |||||||||

| E | 12 cfm @ 100 psi | 250° | 71 dBA @ 80 psi | 1/2" | 1 3/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 00000000 | 00000 |

Nonmarring Air Nozzles

Made from rubber, these nozzles won’t scratch or damage sensitive workpieces.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max.Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | ||

| B | 1/8 | NPSM | Male | 10 cfm @ 100 psi | 175° | 94 dBA @ 80 psi | 9/16" | 1 7/16" | 150 | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| C | 1/8 | NPSM | Male | 10 cfm @ 100 psi | 150° | 91 dBA @ 80 psi | 19/32" | 1" | 150 | Rubber | __ | 00000000 | 0000 |

| C | 1/8 | NPSM | Male | 20 cfm @ 90 psi | Not Rated | 86 dBA @ 80 psi | 5/8" | 1 1/2" | 150 | Rubber | __ | 0000000 | 0000 |

Economy Air Nozzles

Attach to your blowgun to direct airflow.

Nozzles that meet OSHA 29 CFR 1910.242 conform to requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | ||

| A | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 7/16" | 7/8" | 150 | Brass | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 7/16" | 1 7/16" | 150 | Brass | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000 |

| C | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1/2" | 1 3/4" | 150 | Brass | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000 |

Chip-Guard Air Nozzles

Also known as an air-shield and safety-shield nozzle, a center airstream blows away debris while an outer air curtain deflects flying chips and dust. This nozzle conforms to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | |

| 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 3/4" | 13/16" | 150 | Brass | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

Adjustable-Flow Air Nozzles

Control consumption and noise by adjusting the airflow. Loosen the set screw inside the nozzle and twist the tip to change airflow. Tighten the screw to secure the setting. These nozzles conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | |

| Aluminum | 1/8 | NPT | Male | 8 cfm-26 cfm @ 100 psi | 160° | 84 dBA @ 80 psi | 9/16" | 1 7/8" | 150 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

| 304 Stainless Steel | 1/8 | NPT | Male | 8 cfm-26 cfm @ 100 psi | 160° | 84 dBA @ 80 psi | 9/16" | 1 7/8" | 150 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

Extended-Reach Air Nozzles

The extra length allows access into hard-to-reach areas.

Nozzles that meet OSHA 29 CFR 1910.242 conform to requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Lg. | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | Max. Inlet Pressure, psi | Material | Specifications Met | Each | ||

| A | 6" | 1/8 | NPT | Male | 35 cfm @ 100 psi | Not Rated | 104 dBA @ 80 psi | 5/16" | 120 | Brass | __ | 0000000 | 00000 |

| A | 12" | 1/8 | NPT | Male | 35 cfm @ 100 psi | Not Rated | 104 dBA @ 80 psi | 5/16" | 120 | Brass | __ | 0000000 | 00000 |

| A | 18" | 1/8 | NPT | Male | 35 cfm @ 100 psi | Not Rated | 104 dBA @ 80 psi | 5/16" | 120 | Brass | __ | 0000000 | 00000 |

| B | 6 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 8 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 12 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 16 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 18 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 24 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 36 3/8" | 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/16" | 150 | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| D | 6" | 1/8 | NPT | Male | 35 cfm @ 100 psi | 140° | 103 dBA @ 100 psi | 3/16" | 120 | Brass | __ | 0000000 | 0000 |

| D | 12" | 1/8 | NPT | Male | 35 cfm @ 100 psi | 140° | 103 dBA @ 100 psi | 3/16" | 120 | Brass | __ | 000000 | 0000 |

| D | 18" | 1/8 | NPT | Male | 35 cfm @ 100 psi | 140° | 103 dBA @ 100 psi | 3/16" | 120 | Brass | __ | 0000000 | 00000 |

Adjustable-Length Air Nozzles

Extend this telescoping nozzle to increase your reach. It conforms to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Tip Material | Specifications Met | Each | |

| 1/8 | NPSM | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 5/8" | 9 3/8"-32 3/8" | 150 | 304 Stainless Steel | ABS Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

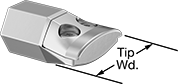

Wide-Airflow Air Nozzles

The flat nozzle tip distributes air over a wider area than focused-airflow nozzles. Volume (dBA) is measured 3 ft. from the nozzle at 80 psi.

Nozzles that are OSHA Compliant 29 CFR 1910.242 conform to requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/8 NPT Male Inlet | ||||||||||

Zinc | ||||||||||

| A | 13 cfm @ 100 psi | 158° | 80 dBA @ 80 psi | 15/16" | 1/8" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 000000 |

316L Stainless Steel | ||||||||||

| A | 17 cfm @ 100 psi | 750° | 84 dBA @ 80 psi | 15/16" | 3/16" | 2 1/4" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/8 NPT Female Inlet | ||||||||||

Zinc | ||||||||||

| A | 25 cfm @ 100 psi | 158° | 85 dBA @ 80 psi | 1 13/16" | 3/16" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 00000000 | 00000 |

1/8 BSPP Male Inlet | ||||||||||

Zinc | ||||||||||

| A | 12 cfm @ 85 psi | 155° | 82 dBA @ 80 psi | 15/16" | 3/16" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

Low-Profile Wide-Airflow Air Nozzles

At less than 2" long and with a wide airflow pattern, these nozzles are ideal for tight spaces where you need to distribute air over a wider area than a focused-airflow nozzle.

Nozzles that meet OSHA 29 CFR 1910.242 conform to requirements for maximum air outlet pressure. Nozzles that meet OSHA 29 CFR 1910.95 conform to requirements for noise.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/8 NPT Male | ||||||||||

316L Stainless Steel | ||||||||||

| A | 14 cfm @ 100 psi | 750° | 81 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 0000000 |

1/8 NPT Female | ||||||||||

Zinc | ||||||||||

| B | 11 cfm @ 80 psi | 250° | 75 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

| B | 18 cfm @ 80 psi | 250° | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

316 Stainless Steel | ||||||||||

| B | 11 cfm @ 80 psi | 1000° | 75 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

| B | 18 cfm @ 80 psi | 1000° | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

1/8 BSPT Female | ||||||||||

Zinc | ||||||||||

| B | 18 cfm @ 80 psi | 250° | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

Right-Angle Wide-Airflow Air Nozzles

Air blows out of these nozzles at a right angle in a wide pattern, distributing air over a wider area than focused-airflow nozzles. All conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Tip | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | |

1/8 NPT Male | |||||||||

Zinc | |||||||||

| 15 cfm @ 100 psi | 155° | 84 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

316L Stainless Steel | |||||||||

| 14 cfm @ 100 psi | 750° | 81 dBA @ 80 psi | 15/16" | 3/16" | 11/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

1/8 BSPP Male | |||||||||

Zinc | |||||||||

| 13 cfm @ 85 psi | 155° | 84 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

Right-Angle Food Industry Wide-Airflow Air Nozzles

Air blows out of these nozzles in a wide pattern at a 90° angle from the inlet, distributing air over a wider area than focused-airflow nozzles. They’re FDA compliant 21 CFR 110.40 for use in the food industry. All conform to OSHA 29 CFR 1910.95 requirements for noise.

For technical drawings and 3-D models, click on a part number.

Tip | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | |

1/8 NPT Male | |||||||||

316 Stainless Steel | |||||||||

| 10 cfm @ 75 psi | 1000° | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | FDA Compliant 21 CFR 110.40, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

1/8 BSPP Male | |||||||||

316 Stainless Steel | |||||||||

| 10 cfm @ 75 psi | 1000° | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | FDA Compliant 21 CFR 110.40, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

Adjustable Wide-Airflow Air Nozzles

Control consumption and noise by loosening or tightening the airflow adjustment screw. The flat shape distributes air over a wider area than focused-airflow nozzles. These blowguns conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Tip | Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | O'all Lg. | Max. Inlet Pressure, psi | Material | Specifications Met | Each | |

| 15/16" | 3/16" | 1/8 | NPT | Male | 0.3 cfm-17 cfm @ 100 psi | 750° | 82 dBA @ 80 psi | 2 3/4" | 145 | 316 Stainless Steel | OSHA Compliant 29 CFR 1910.242 | 00000000 | 0000000 |

Precise-Airflow Air Nozzles

Focus air with pinpoint precision.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Each | |

| 1/8 | NPSM | Male | Not Rated | 175° | 68 dBA @ 100 psi | 1/16" | 1 9/16" | 150 | 304 Stainless Steel | 0000000 | 00000 |

| 1/8 | NPSM | Male | 1 cfm @ 100 psi | 175° | 80 dBA @ 100 psi | 1/16" | 1 13/16" | 150 | 304 Stainless Steel | 0000000 | 0000 |

| 1/8 | NPSM | Male | 5 cfm @ 100 psi | 175° | 91 dBA @ 100 psi | 1/16" | 2 5/16" | 150 | 304 Stainless Steel | 0000000 | 0000 |

| 1/8 | NPSM | Male | 7 cfm @ 100 psi | 175° | 95 dBA @ 100 psi | 1/8" | 3 1/16" | 150 | 304 Stainless Steel | 0000000 | 0000 |

| 1/8 | NPSM | Male | 12 cfm @ 100 psi | 175° | 98 dBA @ 100 psi | 1/8" | 3 5/16" | 150 | 304 Stainless Steel | 0000000 | 0000 |

Precise-Airflow Air Nozzle Sets

Focus air with pinpoint precision.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Pieces | Includes | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Max. Inlet Pressure, psi | Material | Each | |

| 5 | 1/16" Tip OD × 1 9/16" O'all Lg. Nozzle 1/16" Tip OD × 1 13/16" O'all Lg. Nozzle 1/16" Tip OD × 2 5/16" O'all Lg. Nozzle 1/8" Tip OD × 3 1/16" O'all Lg. Nozzle 1/8" Tip OD × 3 5/16" O'all Lg. Nozzle | 1/8 | NPSM | Male | 12 cfm @ 100 psi | 175° | 98 dBA @ 100 psi | 150 | 304 Stainless Steel | 0000000 | 000000 |

Bend-and-Stay Air Nozzles

Nozzles are attached to a flexible hose that bends and holds its shape until you reposition it. They conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure.

For technical drawings and 3-D models, click on a part number.

Air Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure, psi | Material | Hose Material | Specifications Met | Each | ||

| A | 1/8 | NPT | Male | Not Rated | Not Rated | Not Rated | 7/16" | 9" | 30 | Steel | Steel | OSHA Compliant 29 CFR 1910.242 | 0000000 | 000000 |

| B | 1/8 | NPT | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1/2" | 6 9/16" | 150 | Brass | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| B | 1/8 | NPT | Male | 13 cfm @ 100 psi | 150° | 87 dBA @ 80 psi | 1/2" | 12 9/16" | 150 | Brass | Rubber | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

| C | 1/8 | NPT | Male | 14 cfm @ 100 psi | 100° | 85 dBA @ 80 psi | 1/4" | 7 1/2" | 90 | Nylon Plastic | Nylon Plastic | OSHA Compliant 29 CFR 1910.242 | 0000000 | 00000 |

Wedge Air Nozzles

Shaped to fit into extremely tight spaces, these nozzles can be used to remove parts from molds. Tap the wedge into position, attach the nozzle to a blowgun, and activate airflow to release the part.

Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Lg. | Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp. | Volume | Thick. | Tip Wd. | Max. Inlet Pressure | Material | Each | |

| 6 3/4" | 1/8 | NPT | Male | Not Rated | Not Rated | Not Rated | 3/16"-15/16" | 3 3/16" | Not Rated | Polyethylene Plastic | 0000000 | 000000 |

Air Nozzle Swivels

Direct air 30° left, right, up, and down by attaching a swivel to an air nozzle.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | Volume | Swivel Range of Motion | O'all Lg. | Max. Inlet Pressure, psi | Material | Each | |

| 1/8 | NPT | Male | Not Rated | 390° | Not Rated | 30° | 1 3/16" | 145 | 303 Stainless Steel | 0000000 | 000000 |

Blow-and-Spray Air Nozzles

Convert your blowgun to a spray gun. These nozzles spray air and liquids at the same time. Note: Do not use with flammable liquids.

For technical drawings and 3-D models, click on a part number.

Air Inlet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Air Consumption | Max. Temp., °F | For Liquid Inlet Hose ID | Liquid Inlet Gender | Volume | Tip OD | O'all Lg. | Max. Inlet Pressure | Max. Flow Rate | Material | Includes | Each | |

| 1/8 | NPT | Male | Not Rated | 120° | 1/4" | Male | Not Rated | 1/4" | 1 3/8" | Not Rated | Not Rated | Nickel-Plated Steel | 7-ft. Lg. Clear 1/4" ID PVC Tubing | 0000000 | 000000 |

Cold-Air Dispensers

Replace messy mist coolant dispensers—these convert compressed air into a stream of cold air. They can be used in applications where liquid coolant can't. Made with a vortex tube, these dispensers have no moving parts and need no electricity to provide a continuous supply of cold air. Dispensers have any-which-way nozzles that stay in place once positioned. All dispensers come with a filter to install in your air line.

For technical drawings and 3-D models, click on a part number.

Nozzle | Body | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Air Outlets | Airflow | Max. Pressure, psi | Lg. | Material | Mount Type | Bend Radius | No. of Dispensing Tips Included | Dia. | Lg. | Material | Vortex Tube Material | Air Temp. Reduction, °F | Each | |

Magnetic Mount | ||||||||||||||

Fixed Temperature | ||||||||||||||

| 1 | 4 cfm | 100 | 7 1/8" | Acetal Plastic | Threaded | 1 1/4" | 1 | 7/8" | 5 7/8" | Aluminum | Aluminum | 100° | 000000000 | 0000000 |

| 2 | 4 cfm | 100 | 8 1/8" | Acetal Plastic | Threaded | 1 1/4" | 2 | 7/8" | 5 7/8" | Aluminum | Aluminum | 100° | 000000000 | 000000 |

Enclosure-Cooling Vortex Tubes

Vortex tubes convert compressed air into a stream of cold air to keep electronics within enclosures from overheating while also keeping dust and other contaminants out. These vortex tubes chill compressed air by 50° F or more. They include a ducting kit to distribute cool air throughout the enclosure. All are rated NEMA 12 to resist dirt, light water splashes, and oil/coolant dripping.

Replacement filters are sold separately.

Enclosure-Cooling Vortex Tubes with Thermostats

Set the thermostat and these vortex tubes switch on only when needed. They convert compressed air into a stream of cold air to keep electronics within enclosures from overheating while also keeping dust and other contaminants out. These vortex tubes chill compressed air by 50° F or more. They include a ducting kit to distribute cool air throughout the enclosure. All are rated NEMA 12 to resist dirt, light water splashes, and oil/coolant dripping.

Replacement filters are sold separately.

Vortex Tubes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Overall | Replacement Filters | ||||||||||||||

| Cooling Cap., Btu/hr. | Airflow, cfm | Pipe Size | Thread Type | Gender | Required Air Pressure, psi | Volume, dBA | Voltage | Electrical Connection | Frequency | Dia. | Ht. | For Opening Dia. | Each | Each | ||

With Adjustable Thermostat (50° to 140° F) | ||||||||||||||||

Aluminum—NEMA 12 | ||||||||||||||||

| 400 | 5 | 1/8 | NPT | Male | 80-100 | 53 | 120V AC | Wire Leads | 60Hz | 7/8" | 7 1/16" | 1 1/8" | 0000000 | 000000000 | 0000000 | 0000000 |

Low-Noise Weather-Resistant Enclosure-Cooling Vortex Tubes

Quietly cool electronics inside enclosures while keeping out rain, snow, splashing water, and dirt. These vortex tubes have mufflers on both the hot and cold air outlets to reduce noise. They use compressed air, making them a lower-maintenance choice than electric air conditioners. Adjust the ducting to spread air evenly in your enclosure or to cool specific parts. A filter captures and drains moisture from the air to protect your equipment from water damage.

Vortex Tubes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Overall | Replacement Filters | ||||||||||||

| Cooling Capacity, Btu/hr. | Airflow, cfm | Pipe Size | Thread Type | Gender | Required Air Pressure, psi | Volume, dBA | Diameter | Height | For Opening Diameter | Includes | Each | Each | ||

304 Stainless Steel—IP24, NEMA 3R | ||||||||||||||

| 200 | 4 | 1/8 | NPT | Male | 80-100 | 58 | 2 1/4" | 12 1/2" | 2 1/4" | Automatic Water Drain Filter, Cold-Air Muffler, Ducting Kit, Hot-Air Muffler | 0000000 | 0000000 | 0000000 | 0000000 |

| 500 | 8 | 1/8 | NPT | Male | 80-100 | 60 | 2 1/4" | 12 1/2" | 2 1/4" | Automatic Water Drain Filter, Cold-Air Muffler, Ducting Kit, Hot-Air Muffler | 0000000 | 000000 | 0000000 | 000000 |

Weather-Resistant Enclosure-Cooling Vortex Tubes with Thermostats

Cool electronics inside enclosures to your desired temperature while keeping out rain, snow, splashing water, and dirt. After you set the thermostat on these vortex tubes, it works with a solenoid valve to regulate temperature. Cooling turns on and off automatically to cut down on energy use. These vortex tubes use compressed air, making them a lower-maintenance choice than electric air conditioners. Adjust the ducting to spread air evenly in your enclosure or to cool specific parts. A filter captures and drains moisture from the air to protect your equipment from water damage.

Vortex Tubes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Overall | Replacement Filters | ||||||||||||||

| Cooling Capacity, Btu/hr. | Airflow, cfm | Pipe Size | Thread Type | Gender | Required Air Pressure, psi | Volume, dBA | Voltage | Electrical Connection | Diameter | Height | For Opening Diameter | Includes | Each | Each | ||

With Adjustable Thermostat (-50° to 200° F) | ||||||||||||||||

304 Stainless Steel—IP24, NEMA 3R | ||||||||||||||||

| 200 | 4 | 1/8 | NPT | Male | 80-100 | 64 | 120V AC | Wire Leads | 1 1/8" | 6 1/2" | 1 1/8" | Automatic Water Drain Filter, Ducting Kit, Solenoid Valve | 0000000 | 0000000 | 0000000 | 0000000 |

| 500 | 8 | 1/8 | NPT | Male | 80-100 | 66 | 120V AC | Wire Leads | 1 1/8" | 6 1/2" | 1 1/8" | Automatic Water Drain Filter, Ducting Kit, Solenoid Valve | 0000000 | 000000 | 0000000 | 000000 |

Weather-Resistant Enclosure-Cooling Vortex Tubes

Cool electronics inside enclosures while keeping out rain, snow, splashing water, and dirt. These vortex tubes use compressed air, making them a lower-maintenance choice than electric air conditioners. Adjust the ducting to spread air evenly in your enclosure or to cool specific parts. A filter captures and drains moisture from the air to protect your equipment from water damage.

Vortex Tubes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Overall | Replacement Filters | |||||||||||||

| Cooling Capacity, Btu/hr. | Airflow, cfm | Pipe Size | Thread Type | Gender | Required Air Pressure, psi | Volume, dBA | Diameter | Height | For Opening Diameter | Environmental Rating | Includes | Each | Each | ||

304 Stainless Steel—IP24, NEMA 3R | |||||||||||||||

| 200 | 4 | 1/8 | NPT | Male | 80-100 | 64 | 1 1/8" | 6 1/2" | 1 1/8" | IP24, NEMA 3R | Automatic Water Drain Filter, Ducting Kit | 0000000 | 0000000 | 0000000 | 0000000 |

| 500 | 8 | 1/8 | NPT | Male | 80-100 | 66 | 1 1/8" | 6 1/2" | 1 1/8" | IP24, NEMA 3R | Automatic Water Drain Filter, Ducting Kit | 0000000 | 000000 | 0000000 | 000000 |

Low-Noise Weather-Resistant Enclosure-Cooling Vortex Tubes with Thermostats

Quietly cool electronics inside enclosures to your desired temperature while keeping out rain, snow, splashing water, and dirt. After you set the thermostat on these vortex tubes, it works with a solenoid valve to regulate temperature. Cooling turns on and off automatically to cut down on energy use. These vortex tubes have mufflers on both the hot and cold air outlets to reduce noise. Using compressed air, they’re a lower-maintenance choice than electric air conditioners. Adjust the ducting to spread air evenly in your enclosure or to cool specific parts. A filter captures and drains moisture from the air to protect your equipment from water damage.

Vortex Tubes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Overall | Replacement Filters | ||||||||||||||

| Cooling Capacity, Btu/hr. | Airflow, cfm | Pipe Size | Thread Type | Gender | Required Air Pressure, psi | Volume, dBA | Voltage | Electrical Connection | Diameter | Height | For Opening Diameter | Includes | Each | Each | ||

With Adjustable Thermostat (-50° to 200° F) | ||||||||||||||||

304 Stainless Steel—IP24, NEMA 3R | ||||||||||||||||

| 200 | 4 | 1/8 | NPT | Male | 80-100 | 58 | 120V AC | Wire Leads | 2 1/4" | 12 1/2" | 2 1/4" | Automatic Water Drain Filter, Cold-Air Muffler, Ducting Kit, Hot-Air Muffler, Solenoid Valve | 0000000 | 000000000 | 0000000 | 0000000 |

| 500 | 8 | 1/8 | NPT | Male | 80-100 | 60 | 120V AC | Wire Leads | 2 1/4" | 12 1/2" | 2 1/4" | Automatic Water Drain Filter, Cold-Air Muffler, Ducting Kit, Hot-Air Muffler, Solenoid Valve | 0000000 | 00000000 | 0000000 | 000000 |

Equipment-Cooling Vortex Tubes

Vortex tubes convert compressed air into a stream of cold air. Use them to keep heat-sensitive electronic equipment cool with cold air. They have no moving parts for a long service life. Note: Air supply must be filtered to remove moisture and contaminants.

Airflow adjusters (sold separately) can be switched out to increase or decrease the vortex tube's airflow (cfm) to alter its cooling capacity.

Mufflers (sold separately) reduce the sound level to protect your hearing.

Vortex Tubes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Inlet | Air Outlet | Airflow Adjusters | Cold-Air Mufflers | |||||||||||||

| Airflow, cfm | Cooling Cap., Btu/hr. | Volume, dBA | Overall Lg. | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Min. Operating Temp., °F | Each | Each | Each | |||

303 Stainless Steel | ||||||||||||||||

| 2 | 135 | 68 | 4 1/8" | 1/8 | NPT | Male | 1/4 | NPT | Female | -20° | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 |

| 4 | 275 | 70 | 4 1/8" | 1/8 | NPT | Male | 1/4 | NPT | Female | -20° | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

| 8 | 550 | 76 | 4 1/8" | 1/8 | NPT | Male | 1/4 | NPT | Female | -20° | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

Equipment-Cooling Vortex Tube Kits

Kits include one vortex tube for converting compressed air into a stream of cold air as well as airflow adjusters, a cold-air muffler, a tube fitting, and tubing. Use them to keep heat-sensitive electronic equipment cool with cold air. The vortex tube has no moving parts for a long service life. Note: Air supply must be filtered to remove moisture and contaminants.

Air Inlet | Air Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Airflow, cfm | Cooling Cap., Btu/hr. | Overall Lg. | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Min. Operating Temp., °F | Includes | Each | |

303 Stainless Steel | ||||||||||||

| 2, 4, 8 | 135, 275, 550 | 4 1/8" | 1/8 | NPT | Male | 1/4 | NPT | Female | -20° | One Vortex Tube Three Airflow Adjusters One Cold-Air Muffler One Tube Fitting Tubing | 00000000 | 0000000 |

| Filter | 0000000 | Each | 0000000 |