How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

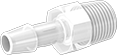

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

For technical drawings and 3-D models, click on a part number.

Cartridges fit into unthreaded ports in your equipment to create a push-to-connect junction with tubing. Install them in equipment such as taps, manifolds, and flow direction splitters as an alternative to installing a threaded port. They have a release ring, a grasping ring for securing the tubing, and an O-ring.

Release Ring | Required Hole Dia. For | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Material | Color | Max. Pressure | Grasping Ring | O-Ring | Tube Stop | Hole Dia. Tolerance | Max. Through Hole Dia. | Each | |

| 3/8" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.593" | 0.516" | 0.38" | -0.001" to 0.001" | 0.3" | 00000000 | 00000 |

Universal-Thread Nickel-Plated Brass

Push-to-Connect Tube Fittings for Air and Water

Threads

with Gasket

- Temperature Range: 0° to 175° F

- Tubing: Use with firm (Durometer 85A-100A) nylon plastic or polyurethane rubber

- Specifications Met: ISO 14743

Made of nickel-plated brass, these tube fittings resist corrosion better than plain brass fittings. The male threaded ends connect to NPT, NPTF, BSPP, BSPT, and other universal threads, so you don’t have to bother matching exact thread types. They also have a reusable gasket to protect against leaks. The tube ends connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect them, push the release ring and pull the tubing out of the fitting. These fittings are sometimes called instant fittings. All meet ISO 14743, which is an international standard for push-to-connect fittings for plastic tubing.

For technical drawings and 3-D models, click on a part number.

Threads

with Gasket

Nickel-Plated Brass Release Ring | ||||||

|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Gasket Material | Maximum Pressure | Each | |

BSPP, BSPT, NPT, NPTF, Universal Threads | ||||||

| 1/8" | 1/8 | Nickel-Plated Brass | Buna-N Rubber | 290 psi @ 72° F | 00000000 | 00000 |

Moisture-Resistant Push-to-Connect Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water,

except Manifolds with Swivel: Air, Water - Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

These fittings won’t absorb moisture, so they’re good for water and high-humidity air applications. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. They have good corrosion resistance.

Nickel-plated brass fittings have better corrosion resistance than unfinished brass fittings.

Fittings with thread sealant offer extra protection against leaks.

For technical drawings and 3-D models, click on a part number.

Release Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Color | Max. Pressure | Features | Choose a Material | Each | |

NPT Threads | ||||||||

| 1/8" | 1/4 | Plastic | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 00000 | |

| 5/32" | 1/4 | Plastic | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

| 3/16" | 1/4 | Plastic | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

| 1/4" | 1/4 | Plastic | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

Aluminum Low-Pressure Barbed Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water

- Temperature Range: -40° to 230° F

- Tubing: Use with hard (Durometer 75A-60D) EVA plastic, polyethylene plastic, polyurethane rubber or PVDF plastic

Made of aluminum, these fittings are lighter in weight than other metal barbed tube fittings and have good corrosion resistance. The barb grips onto tubing, providing a secure hold with no clamp required.

UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

Nickel-Plated Brass Low-Pressure Barbed Tube Fittings for Air and Water

The nickel plating on these brass fittings provides extra protection against corrosive environments. The plating won’t peel or chip, so the fittings keep a bright, polished appearance. The barbs grip onto tubing, providing a secure hold with no clamp required.

UN/UNF (SAE Straight) and BSPP male threads have an O-ring to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

(SAE Straight) and BSPP

Male Threads with Gasket

- Temperature Range: -40° to 230° F,

except UN/UNF (SAE Straight) Threads: -20° to 160° F - Tubing: Use with hard (Durometer 60D-90D) Buna-N rubber, EVA plastic, Nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PTFE plastic, PVC plastic, PVDF plastic, or silicone rubber,

except UN/UNF (SAE Straight) Threads: Use with firm (Durometer 85A) polyurethane rubber

| For Tube ID | Thread Size | Material | Max. Pressure | Each | |

UN/UNF (SAE Straight) Threads | |||||

|---|---|---|---|---|---|

| 1/8" | 10-32 | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 00000 |

Stainless Steel High-Pressure Barbed Tube Fittings for Air and Water

- Temperature Range: See table

- Tubing: Use with firm (Durometer 75A-95A) EVA plastic, polyethylene plastic, polypropylene plastic or PVC plastic

Fittings withstand pressures up to 250 psi. They are 303 stainless steel for very good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Tight-Seal Plastic Barbed Tube Fittings for Air and Water

Minimize leaks in your line—these fittings have a single barb that creates a smooth clamping surface for extra-tight connections. Fittings are nylon for excellent impact and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

Tight-Seal Moisture-Resistant Plastic Barbed Tube Fittings for Air and Water

- Temperature Range: -20° to 280° F

- Tubing: Use with firm or soft (Durometer 50A-90A) polyurethane rubber or PVC plastic

- Specifications Met: FDA Compliant 21 CFR 177.2470

Fittings have a single barb that creates a smooth clamping surface for extra-tight connections that minimize leaks. Made of acetal, they won’t absorb water and lose strength, even in high-humidity environments.

For technical drawings and 3-D models, click on a part number.

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Each | |

UNF Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8" | 10-32 | Acetal Plastic | White | Semi-Clear | Not Rated | 0000000 | 00000 |

Brass Quick-Turn Tube Couplings for Air

An all-brass body gives these couplings better strength and durability than plastic quick-turn couplings. They have a nickel plating for extra protection against corrosive environments. Also known as luer lock couplings, they consist of a plug and socket (sold separately) that connect with a half turn. They have a compact body, so they’re easy to fit in tight spaces. Plugs and sockets are open-flow style, so there is no shut-off valve to stop the flow when the coupling is separated. They have a universal connection, so the plugs will connect to any of the sockets, regardless of the pipe or tube size.

Note: For a complete coupling, order a plug and a socket.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -100° to 300° F

Plugs | |||

|---|---|---|---|

| Material | Max. Pressure | Each | |

| Nickel-Plated Brass | 30 psi @ 72° F | 000000000 | 00000 |

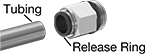

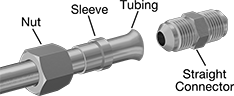

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 3/16" | 316 Stainless Steel | -380° to 800° | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 3/16" | 316 Stainless Steel | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 3/16" | 316 Stainless Steel | 000000000 | 00000 |

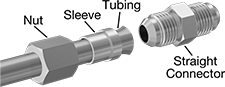

High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Air, Dairy, Water

- Temperature Range: See Gaskets

- Tubing:

Inch Butt-Weld Fittings and Quick-Clamp Fittings: Use with welded 304/304L or 316/316L stainless steel that meets ASTM 269 or ASTM 27

Metric Butt-Weld Fittings: Use with welded or seamless 316 stainless steel - Specifications Met:

304 Stainless Steel Adapters, Caps, and Nuts: 3-A Certified 63-04

Gaskets: See table

Join these fittings with a threaded nut and a gasket for a secure connection that grants you easy access to your line. Also known as bevel seat fittings, the fittings are beveled to fit snugly around the gasket, creating a vibration-resistant seal. Fittings are polished to a smooth finish on the interior to prevent product buildup and bacterial growth.

304 stainless steel fittings have very good corrosion resistance. They’re 3-A certified to meet sanitary design standards.

Note: For a complete connection, you’ll need a threaded straight adapter, an unthreaded straight adapter, a gasket, and a nut (all sold separately unless noted).

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Material | Max. Pressure | Each | |

| 2 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 000000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 2 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 000000 |

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 1/2" | 2.340" | 2.950" | 0.35" | -30° to 200° | Black | __ | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 2 1/2" | 2.340" | 2.950" | 0.35" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

316 Stainless Steel/PTFE Plastic Blend | ||||||||

| 2 1/2" | 2.340" | 2.950" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 3/16" | Zinc-Plated Steel | 7,500 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

For Tube OD | ||||

|---|---|---|---|---|

| Inch | Sleeve Material | Max. Pressure | Each | |

Inch Sleeves | ||||

| 3/16" | Zinc-Plated Steel | 1,250 psi @ 72° F | 00000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 3/16" | Zinc-Plated Steel | 1,200 psi @ 72° F | 00000000 | 00000 |