Select a cylinder, prolong its life by reducing wear, and trigger automated processes with sensors.

Clean Room Round Body Air Cylinders

Minimize the release of particles that can damage electronics or contaminate batches as you push and pull light loads. These air cylinders are designed with seals and caps that prevent particles from escaping. A rod seal wipes grease particles off the rod as it moves back and forth. The seal is polyurethane, which is slippery, so it wears more slowly than standard seals, releasing fewer particles. These cylinders also have tightly crimped end caps to stop air from leaking.

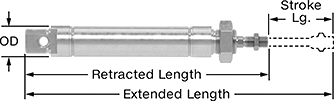

With no tie rods on the outside, these round-body cylinders fit in tight spaces. They have an ISO industry-standard footprint that fits common mounting patterns for easy interchangeability. As universal-mount cylinders, they have mounting threads on both ends, giving you more mounting options than nose-mount cylinders. You can also pivot mount them with the through-hole on the back. They’re double acting, meaning they push and pull loads with equal force.

The piston is magnetic, so you can use these cylinders with sensors (sold separately) to activate relays and controllers. When the piston moves past a sensor, the sensor activates. You can use multiple sensors—one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

Lg., mm | Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Environmental Rating | Air Cushion Type | Body Material | Rod Thread Size | Pipe Size | Thread Type | Gender | Specifications Met | Each | |

20mm Bore Size (21mm OD) | |||||||||||||

| 25 | 157 | 182 | 48 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M8 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 000000 |

| 50 | 182 | 232 | 48 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M8 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 70 | 202 | 272 | 48 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M8 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 100 | 232 | 332 | 48 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M8 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 125 | 257 | 382 | 48 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M8 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

25mm Bore Size (27mm OD) | |||||||||||||

| 25 | 166.5 | 191.5 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 50 | 191.5 | 241.5 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 70 | 211.5 | 281.5 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 100 | 241.5 | 341.5 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 00000 |

| 125 | 266.5 | 391.5 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | ISO 6432 | 0000000 | 000000 |

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

| Shank Thread Size | ID, mm | Max. Ball Swivel | O'all Wd., mm | O'all Thick., mm | Shank Center Lg., mm | Shank Thread Lg., mm | Static Radial Load Cap., lbs. | Material | Shank Thread Direction | Each | |

| M8 × 1.25 mm | 8 | 18° | 22 | 12 | 36 | 17 | 7,450 | Zinc-Plated Chrome-Moly Steel | Right Hand | 00000000 | 000000 |

| M10 × 1.25 mm | 10 | 17° | 27 | 14 | 43 | 21 | 11,250 | Zinc-Plated Chrome-Moly Steel | Right Hand | 00000000 | 00000 |