Select a cylinder, prolong its life by reducing wear, and trigger automated processes with sensors.

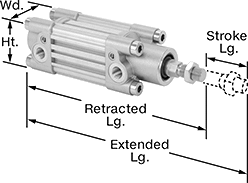

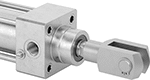

Enclosed-Body ISO Air Cylinders

An extruded-aluminum body means these cylinders have no open spaces for debris to collect. They have an ISO industry-standard footprint to match common mounting patterns for easy interchangeability. These cylinders are double-acting, so they exert force in both directions. To minimize wear and reduce noise, they cushion the impact of the piston with air. Adjust the amount of cushion with a screw at each port. All have a magnetic piston so, you can use them with sensors (sold separately) to activate relays and controllers. You can use multiple sensors—attach one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

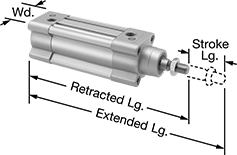

Lg., mm | Air Inlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Body Material | Pipe Size | Thread Type | Gender | Each | |

32 mm Bore Size (46.5 mm Wd.) | |||||||||

| 25 | 171 | 196 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 0000000 |

| 50 | 196 | 246 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 75 | 221 | 296 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 100 | 246 | 346 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 125 | 271 | 396 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 150 | 296 | 446 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 175 | 321 | 496 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 200 | 346 | 546 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 225 | 371 | 596 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 250 | 396 | 646 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 275 | 421 | 696 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

| 300 | 446 | 746 | 125 | Aluminum | 1/8 | BSPP | Female | 000000000 | 000000 |

40 mm Bore Size (53 mm Wd.) | |||||||||

| 25 | 188 | 213 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 50 | 213 | 263 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 75 | 238 | 313 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 100 | 263 | 363 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 125 | 288 | 413 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 150 | 313 | 463 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 175 | 338 | 513 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 200 | 363 | 563 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 225 | 388 | 613 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 250 | 413 | 663 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 275 | 438 | 713 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

| 300 | 463 | 763 | 195 | Aluminum | 1/4 | BSPP | Female | 000000000 | 000000 |

63 mm Bore Size (75 mm Wd.) | |||||||||

| 25 | 219 | 244 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 50 | 244 | 294 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 75 | 269 | 344 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 100 | 294 | 394 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 125 | 319 | 444 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 150 | 344 | 494 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 175 | 369 | 544 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 200 | 394 | 594 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 225 | 419 | 644 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 250 | 444 | 694 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 275 | 469 | 744 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

| 300 | 494 | 794 | 483 | Aluminum | 3/8 | BSPP | Female | 000000000 | 000000 |

Connect these mounts to an air cylinder to create linear, pivot, or arc movements. These mounts are compatible with ISO tie rod air cylinders.

Front or rear flanges are for straightforward, back-and-forth movements, such as opening a sliding door. These flanges mount to either end of your cylinder.

Pivot brackets and clevis brackets work together to allow the rear portion of cylinders to pivot back and forth. Use either with a rod clevis to create arcing movements, such as opening a swinging door. Rod clevises allow the front portion of cylinders to pivot.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Connect these mounts to an air cylinder to create linear, pivot, or arc movements. These mounts are compatible with ISO tie rod air cylinders.

Front or rear flanges are for straightforward, back-and-forth movements, such as opening a sliding door. These flanges mount to either end of your cylinder.

Pivot brackets and clevis brackets work together to allow the rear portion of cylinders to pivot back and forth. Use either with a rod clevis to create arcing movements, such as opening a swinging door. Rod clevises allow the front portion of cylinders to pivot.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Connect these mounts to an air cylinder to create linear, pivot, or arc movements. These mounts are compatible with ISO tie rod air cylinders.

Front or rear flanges are for straightforward, back-and-forth movements, such as opening a sliding door. These flanges mount to either end of your cylinder.

Pivot brackets and clevis brackets work together to allow the rear portion of cylinders to pivot back and forth. Use either with a rod clevis to create arcing movements, such as opening a swinging door. Rod clevises allow the front portion of cylinders to pivot.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

| For Bore Size | AC Voltage | DC Voltage | Electrical Connection | Temperature Range, °F | Each | |

Reed Switch | ||||||

|---|---|---|---|---|---|---|

| 32mm, 40mm, 63mm | 12V AC- 240V AC | 12V DC- 60V DC | Wire Leads | -4° to 176° | 00000000 | 0000000 |

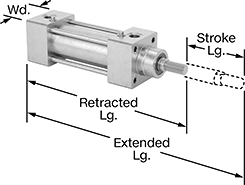

Mounts for ISO Tie Rod Air Cylinders

Connect these mounts to an air cylinder to create linear, pivot, or arc movements. These mounts are compatible with ISO tie rod air cylinders.

Front or rear flanges are for straightforward, back-and-forth movements, such as opening a sliding door. These flanges mount to either end of your cylinder.

Pivot brackets and clevis brackets work together to allow the rear portion of cylinders to pivot back and forth. Use either with a rod clevis to create arcing movements, such as opening a swinging door. Rod clevises allow the front portion of cylinders to pivot.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

For technical drawings and 3-D models, click on a part number.

Inside Mounting Holes | Outside Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Specifications Met | Each | |

| 32 | 45 | 80 | 10 | 4 | 6.6 | 32 | Yes | 4 | 7 | 64 | No | Stainless Steel | ISO 15552 | 0000000 | 0000000 |

| 40 | 52 | 90 | 10 | 4 | 6.6 | 36 | Yes | 4 | 9 | 72 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 50 | 65 | 110 | 12 | 4 | 9 | 45 | Yes | 4 | 9 | 90 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 63 | 75 | 120 | 12 | 4 | 9 | 50 | Yes | 4 | 9 | 100 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 80 | 95 | 150 | 16 | 4 | 11 | 63 | Yes | 4 | 12 | 126 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

Mounting Hole | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Pin Hole Dia., mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Includes | Specifications Met | Each | |

| 32 | 10 | 48 | 48 | 32 | 10 | 4 | 6 | 32.5 | Yes | Aluminum | Four Bolts | ISO 15552 | 00000000 | 000000 |

| 32 | 10 | 51 | 31 | 34 | 8 | 4 | 6.6 | 38 | No | Stainless Steel | __ | ISO 15552 | 0000000 | 000000 |

| 40 | 12 | 53 | 53 | 37 | 10 | 4 | 6 | 38 | Yes | Aluminum | Four Bolts | ISO 15552 | 00000000 | 00000 |

| 40 | 12 | 54 | 35 | 37 | 10 | 4 | 6.6 | 41 | No | Stainless Steel | __ | ISO 15552 | 0000000 | 000000 |

| 50 | 12 | 65 | 45 | 46 | 12 | 4 | 9 | 50 | No | Stainless Steel | __ | ISO 15552 | 0000000 | 000000 |

| 63 | 16 | 67 | 50 | 51 | 14 | 4 | 9 | 52 | No | Stainless Steel | __ | ISO 15552 | 0000000 | 000000 |

| 63 | 16 | 73 | 73 | 48 | 12 | 4 | 8 | 56.5 | Yes | Aluminum | Four Bolts | ISO 15552 | 00000000 | 00000 |

| 80 | 16 | 86 | 60 | 64 | 14 | 4 | 11 | 66 | No | Stainless Steel | __ | ISO 15552 | 0000000 | 000000 |

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Specifications Met | Each | |

| 32 | 45 | 45 | 32 | 26 | 9 | 4 | 6.6 | 32.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 0000000 |

| 40 | 52 | 52 | 37 | 28 | 9 | 4 | 6.6 | 38 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 50 | 60 | 60 | 49 | 32 | 11 | 4 | 9 | 45.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 63 | 70 | 70 | 48 | 40 | 11 | 4 | 9 | 56.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 80 | 90 | 90 | 52 | 50 | 14 | 4 | 11 | 72 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

Pin | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Material | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Includes | Specifications Met | Each | |

| 32 | 10 | Steel | 49 | 49 | 32 | 26 | 10 | 4 | 6 | 32.5 | Yes | Aluminum | Four Bolts, Pin, Retaining Clip | ISO 15552 | 00000000 | 000000 |

| 40 | 12 | Steel | 53 | 53 | 38 | 28 | 10 | 4 | 6 | 38 | Yes | Aluminum | Four Bolts, Pin, Retaining Clip | ISO 15552 | 00000000 | 00000 |

| 63 | 16 | Steel | 73 | 73 | 49 | 40 | 14 | 4 | 8 | 56.5 | Yes | Aluminum | Four Bolts, Pin, Retaining Clip | ISO 15552 | 00000000 | 00000 |

Pin | Shank | Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Lg., mm | Material | Lg., mm | Ht., mm | Jaw Opening Wd., mm | Center Lg., mm | Gender | Size | Pitch, mm | Spacing | Lg., mm | Material | Includes | Each | |

| 32 | 10 | 26 | Stainless Steel | 52 | 22 | 10 | 40 | Female | M10 | 1.25 | Fine | 20 | Stainless Steel | Pin, Retaining Rings | 0000000 | 000000 |

| 32 | 10 | 26 | Steel | 52 | 20 | 10 | 40 | Female | M10 | 1.25 | Fine | 19 | Steel | Retaining Clip | 00000000 | 00000 |

| 40 | 12 | 31 | Steel | 62 | 24 | 12 | 48 | Female | M12 | 1.25 | Extra Fine | 25 | Steel | Retaining Clip | 00000000 | 00000 |

| 40 | 12 | 32 | Stainless Steel | 62 | 28 | 12 | 48 | Female | M12 | 1.25 | Extra Fine | 22 | Stainless Steel | Pin, Retaining Rings | 0000000 | 00000 |

| 50, 63 | 16 | 40 | Stainless Steel | 83 | 36 | 16 | 64 | Female | M16 | 1.5 | Fine | 30 | Stainless Steel | Pin, Retaining Rings | 0000000 | 00000 |

| 63 | 16 | 39 | Steel | 83 | 32 | 16 | 64 | Female | M16 | 1.5 | Fine | 32 | Steel | Retaining Clip | 00000000 | 00000 |

| 80 | 20 | 40 | Stainless Steel | 105 | 36 | 20 | 80 | Female | M20 | 1.5 | Extra Fine | 38 | Stainless Steel | Pin, Retaining Rings | 0000000 | 000000 |

| For Bore Size, mm | Dia., mm | Groove Wd., mm | Lg., mm | Usable Lg., mm | Material | Includes | Each | |

| 32 | 10 | 1.1 | 53 | 46 | Stainless Steel | Two Retaining Rings | 0000000 | 000000 |

| 40 | 12 | 1.1 | 60 | 53 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 50 | 12 | 1.1 | 68 | 61 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 63 | 16 | 1.1 | 78 | 71 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 80 | 16 | 1.1 | 98 | 91 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

Corrosion-Resistant ISO Tie Rod Air Cylinders

Our most corrosion-resistant air cylinders, these cylinders are made of stainless steel for use in wet environments. Rods secure the end caps and shield the barrel from impact. These air cylinders are double acting, meaning they push and pull loads with nearly equal force. They have an ISO industry-standard footprint to match common mounting patterns, so they’re easy to switch in and out across equipment.

The magnetic piston inside these cylinders can activate relays and controllers when used with a sensor (sold separately). When the piston moves past the sensor, the sensor activates. You can use multiple sensors—attach one for each action to trigger.

For technical drawings and 3-D models, click on a part number.

Lg., mm | Air Inlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Body Material | Pipe Size | Thread Type | Gender | Specifications Met | Each | |

32 mm Bore Size (50 mm Wd.) | ||||||||||

| 25 | 171 | 196 | 122 | 304 Stainless Steel | 1/8 | BSPP | Female | ISO 15552 | 0000000 | 0000000 |

| 50 | 196 | 246 | 122 | 304 Stainless Steel | 1/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 100 | 246 | 346 | 122 | 304 Stainless Steel | 1/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 150 | 296 | 446 | 122 | 304 Stainless Steel | 1/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 200 | 346 | 546 | 122 | 304 Stainless Steel | 1/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

40 mm Bore Size (55 mm Wd.) | ||||||||||

| 25 | 188 | 213 | 193 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 50 | 213 | 263 | 193 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 100 | 263 | 363 | 193 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 150 | 313 | 463 | 193 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 200 | 363 | 563 | 193 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

50 mm Bore Size (65 mm Wd.) | ||||||||||

| 25 | 204 | 229 | 300 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 50 | 229 | 279 | 300 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 100 | 279 | 379 | 300 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 150 | 329 | 479 | 300 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 200 | 379 | 579 | 300 | 304 Stainless Steel | 1/4 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

63 mm Bore Size (75 mm Wd.) | ||||||||||

| 25 | 219 | 244 | 478 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 50 | 244 | 294 | 478 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 100 | 294 | 394 | 478 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 150 | 344 | 494 | 478 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 200 | 394 | 594 | 478 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

80 mm Bore Size (95 mm Wd.) | ||||||||||

| 25 | 243 | 268 | 770 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 50 | 268 | 318 | 770 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 100 | 318 | 418 | 770 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 150 | 368 | 518 | 770 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

| 200 | 418 | 618 | 770 | 304 Stainless Steel | 3/8 | BSPP | Female | ISO 15552 | 0000000 | 000000 |

Inside Mounting Holes | Outside Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Specifications Met | Each | |

| 32 | 45 | 80 | 10 | 4 | 6.6 | 32 | Yes | 4 | 7 | 64 | No | Stainless Steel | ISO 15552 | 0000000 | 0000000 |

| 40 | 52 | 90 | 10 | 4 | 6.6 | 36 | Yes | 4 | 9 | 72 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 50 | 65 | 110 | 12 | 4 | 9 | 45 | Yes | 4 | 9 | 90 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 63 | 75 | 120 | 12 | 4 | 9 | 50 | Yes | 4 | 9 | 100 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 80 | 95 | 150 | 16 | 4 | 11 | 63 | Yes | 4 | 12 | 126 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Pin Hole Dia., mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Specifications Met | Each | |

| 32 | 10 | 51 | 31 | 34 | 8 | 4 | 6.6 | 38 | No | Stainless Steel | ISO 15552 | 0000000 | 0000000 |

| 40 | 12 | 54 | 35 | 37 | 10 | 4 | 6.6 | 41 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 50 | 12 | 65 | 45 | 46 | 12 | 4 | 9 | 50 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 63 | 16 | 67 | 50 | 51 | 14 | 4 | 9 | 52 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 80 | 16 | 86 | 60 | 64 | 14 | 4 | 11 | 66 | No | Stainless Steel | ISO 15552 | 0000000 | 000000 |

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Specifications Met | Each | |

| 32 | 45 | 45 | 32 | 26 | 9 | 4 | 6.6 | 32.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 0000000 |

| 40 | 52 | 52 | 37 | 28 | 9 | 4 | 6.6 | 38 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 50 | 60 | 60 | 49 | 32 | 11 | 4 | 9 | 45.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 63 | 70 | 70 | 48 | 40 | 11 | 4 | 9 | 56.5 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

| 80 | 90 | 90 | 52 | 50 | 14 | 4 | 11 | 72 | Yes | Stainless Steel | ISO 15552 | 0000000 | 000000 |

Pin | Shank | Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Lg., mm | Material | Lg., mm | Ht., mm | Jaw Opening Wd., mm | Center Lg., mm | Gender | Size | Pitch, mm | Spacing | Lg., mm | Material | Includes | Each | |

| 32 | 10 | 26 | Stainless Steel | 52 | 22 | 10 | 40 | Female | M10 | 1.25 | Fine | 20 | Stainless Steel | Pin, Retaining Rings | 0000000 | 000000 |

| 40 | 12 | 32 | Stainless Steel | 62 | 28 | 12 | 48 | Female | M12 | 1.25 | Extra Fine | 22 | Stainless Steel | Pin, Retaining Rings | 0000000 | 00000 |

| 50, 63 | 16 | 40 | Stainless Steel | 83 | 36 | 16 | 64 | Female | M16 | 1.5 | Fine | 30 | Stainless Steel | Pin, Retaining Rings | 0000000 | 00000 |

| 80 | 20 | 40 | Stainless Steel | 105 | 36 | 20 | 80 | Female | M20 | 1.5 | Extra Fine | 38 | Stainless Steel | Pin, Retaining Rings | 0000000 | 000000 |

| For Bore Size, mm | Dia., mm | Groove Wd., mm | Usable Lg., mm | Lg., mm | Material | Includes | Each | |

| 32 | 10 | 1.1 | 46 | 53 | Stainless Steel | Two Retaining Rings | 0000000 | 000000 |

| 40 | 12 | 1.1 | 53 | 60 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 50 | 12 | 1.1 | 61 | 68 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 63 | 16 | 1.1 | 71 | 78 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| 80 | 16 | 1.1 | 91 | 98 | Stainless Steel | Two Retaining Rings | 0000000 | 00000 |

| For Bore Size | AC Voltage | DC Voltage | Each | |

| 1 1/4", 1 3/4", 2", 2 1/2", 3", 3 1/2", 4 1/2", 32mm, 40mm, 50mm, 63mm, 80mm | 5V AC- 240V AC | 5V DC- 240V DC | 00000000 | 000000 |

Enclosed-Body Load Responsive Cushion Air Cylinders

Ensure the correct cushioning, even with changing loads. These cylinders have self-adjusting cushions that automatically compensate for changes in load and speed. They have an extruded-aluminum body so there's no open spaces for debris to collect. All have a magnetic piston so you can use them with sensors (sold separately) to activate relays and controllers.

For technical drawings and 3-D models, click on a part number.

Lg., mm | Air Inlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Body Material | Pipe Size | Thread Type | Gender | Specifications Met | Each | |

32 mm Bore Size (45 mm Wd.) | ||||||||||

| 25 | 170.1 | 195.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 0000000 |

| 50 | 195.1 | 245.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 75 | 220.1 | 295.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 100 | 245.1 | 345.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 125 | 270.1 | 395.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 150 | 295.1 | 445.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 175 | 320.1 | 495.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 200 | 345.1 | 545.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 275 | 420.1 | 695.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 350 | 495.1 | 845.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 400 | 545.1 | 945.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 500 | 645.1 | 1,145.1 | 114 | Aluminum | 1/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

40 mm Bore Size (54 mm Wd.) | ||||||||||

| 25 | 186.9 | 211.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 50 | 211.9 | 261.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 75 | 236.9 | 311.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 100 | 261.9 | 361.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 125 | 286.9 | 411.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 150 | 311.9 | 461.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 175 | 336.9 | 511.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 200 | 361.9 | 561.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 250 | 411.9 | 661.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 300 | 461.9 | 761.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 350 | 511.9 | 861.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 400 | 561.9 | 961.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 450 | 611.9 | 1,061.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 500 | 661.9 | 1,161.9 | 178 | Aluminum | 1/4 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

63 mm Bore Size (75 mm Wd.) | ||||||||||

| 50 | 243.1 | 293.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 75 | 268.1 | 343.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 100 | 293.1 | 393.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 125 | 318.1 | 443.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 150 | 343.1 | 493.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 175 | 368.1 | 543.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 200 | 393.1 | 593.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 250 | 443.1 | 693.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 300 | 493.1 | 793.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 325 | 518.1 | 843.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 400 | 593.1 | 993.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

| 500 | 693.1 | 1,193.1 | 441 | Aluminum | 3/8 | BSPP | Female | ISO 15552, ISO 6431 | 00000000 | 000000 |

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Pin Hole Dia., mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Includes | Each | |

| 32 | 10 | 45 | 45 | 37 | 5.5 | 4 | 6.6 | 32.5 | Yes | Aluminum | Four Bolts | 00000000 | 000000 |

| 40 | 12 | 54 | 54 | 42 | 5.5 | 4 | 6.6 | 38 | Yes | Aluminum | Four Bolts | 00000000 | 00000 |

| 63 | 16 | 75 | 75 | 55 | 6.5 | 4 | 9 | 56.5 | Yes | Aluminum | Four Bolts | 00000000 | 000000 |

Pin | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Lg., mm | Material | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Includes | Each | |

| 32 | 10 | 41 | Steel | 45 | 45 | 32 | 14 | 5.5 | 4 | 6.6 | 32.5 | Yes | Aluminum | Four Bolts, Retaining Clip | 00000000 | 000000 |

| 40 | 12 | 48 | Steel | 54 | 54 | 37 | 16 | 5.5 | 4 | 6.6 | 38 | Yes | Aluminum | Four Bolts, Retaining Clip | 00000000 | 00000 |

| 63 | 16 | 60 | Steel | 75 | 75 | 48 | 21 | 6.5 | 4 | 9 | 56.5 | Yes | Aluminum | Four Bolts, Retaining Clip | 00000000 | 00000 |

Pin | Shank | Thread | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Lg., mm | Material | Lg., mm | Ht., mm | Jaw Opening Wd., mm | Center Lg., mm | Gender | Size | Pitch, mm | Lg., mm | No. of Mounting Holes | Mounting Hardware Included | Material | Includes | Specifications Met | Each | |

| 32 | 10 | 26 | Steel | 52 | 20 | 10 | 40 | Female | M10 | 1.25 | 20 | 4 | Yes | Galvanized Steel | Nut | DIN 71752, ISO 8140 | 00000000 | 000000 |

| 40 | 12 | 31 | Steel | 62 | 24 | 12 | 48 | Female | M12 | 1.25 | 24 | 4 | Yes | Galvanized Steel | Nut | DIN 71752, ISO 8140 | 00000000 | 00000 |

| 63 | 16 | 39 | Steel | 83 | 32 | 16 | 64 | Female | M16 | 1.5 | 32 | 4 | Yes | Galvanized Steel | Nut | DIN 71752, ISO 8140 | 00000000 | 00000 |