About Air Conditioner Cooling Capacity

More

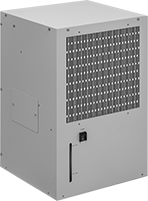

High-Capacity Heat Sinks for Oil

For greater cooling capacity and higher flow rates than other heat sinks for oil, these have a large fan. Also known as oil coolers, they're commonly used to cool hydraulic fluid and lubricating oil in cylinders and compressors. Cooling capacity is based on an initial temperature difference of 50° F.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Thread Size | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | SAE Trade Size | Each | |

Female UN/UNF (SAE Straight) Threaded—For Use with Oil | |||||||||||

| 12,000 | 1 1/16"-12 | 13 3/4" | 13 3/4" | 12 9/16" | Aluminum | 377 | 30 | 250° | #12 | 00000000 | 000000000 |

| 20,000 | 1 1/16"-12 | 14 1/2" | 14 1/8" | 16 15/16" | Aluminum | 377 | 35 | 250° | #12 | 0000000 | 00000000 |

Overall | Bolt Hole | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Thread Size | Ht. | Wd. | Dp. | SAE Flange Size | Dia. | No. of | Ctr.-to-Ctr. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | SAE Trade Size | Each | ||

Female UN/UNF (SAE Straight) Threaded—For Use with Oil | ||||||||||||||||

| A | 7,500 | 1 5/16"-12 | 11 13/16" | 14 13/16" | 20" | __ | __ | __ | __ | Aluminum, Copper | 300 | 20 | 400° | #16 | 00000000 | 000000000 |

| A | 13,800 | 1 5/16"-12 | 13 1/8" | 19" | 19 1/4" | __ | __ | __ | __ | Aluminum, Copper | 300 | 25 | 400° | #16 | 00000000 | 00000000 |

| B | 27,000 | 1 5/16"-12 | 15 15/16" | 16 1/8" | 14 3/16" | __ | __ | __ | __ | Aluminum | 377 | 50 | 250° | #16 | 0000000 | 00000000 |

| B | 32,000 | 1 5/16"-12 | 15 15/16" | 16 9/16" | 16" | __ | __ | __ | __ | Aluminum | 377 | 65 | 250° | #16 | 00000000 | 00000000 |

| B | 44,000 | 1 5/8"-12 | 19 9/16" | 22" | 15 3/8" | __ | __ | __ | __ | Aluminum | 377 | 60 | 250° | #20 | 00000000 | 00000000 |

| B | 76,000 | 1 5/8"-12 | 24" | 25 9/16" | 16 3/4" | __ | __ | __ | __ | Aluminum | 377 | 65 | 250° | #20 | 0000000 | 00000000 |

| B | 90,000 | 1 5/8"-12 | 24" | 26 3/8" | 18" | __ | __ | __ | __ | Aluminum | 377 | 75 | 250° | #20 | 0000000 | 00000000 |

| B | 126,000 | 1 5/8"-12 | 25 7/8" | 30 5/16" | 19 1/2" | __ | __ | __ | __ | Aluminum | 377 | 80 | 250° | #20 | 00000000 | 00000000 |

SAE Flange—For Use with Oil | ||||||||||||||||

| B | 205,000 | __ | 30 3/16" | 37" | 23 3/16" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 377 | 115 | 250° | __ | 00000000 | 00000000 |

| B | 238,000 | __ | 33 1/4" | 39" | 23 3/8" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 377 | 120 | 250° | __ | 00000000 | 00000000 |

| B | 356,000 | __ | 38 3/8" | 43 5/8" | 29 1/2" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 250 | 150 | 250° | __ | 00000000 | 000000000 |

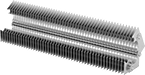

Heat Sinks for Oil

Dozens of fins and coolant tubes quickly dissipate excess heat. Also known as oil coolers, these heat sinks cool hydraulic fluid and lubricating oil in cylinders and compressors. Cooling and flow capacities are based on 50 SSU oil, 1,000 feet per minute of air, a 50° F initial temperature difference, and a 10 psi pressure drop.

Heat sinks with a bypass prevent damage to the cooling fins by diverting pressurized oil. They’re often used in machines that are started up while cold. Once the oil heats up and the pressure drops, flow through the cooling tubes resumes.

Mounting kits (sold separately) are required for installation.

Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | No. of Mount. Kits Required | Each | |

Copper Tube—For Use with Oil | |||||||||||||

| 3,300 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 0000000 | 0000000 |

| 6,100 | 1/2 | NPT | Female | 6 1/2" | 18" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 0000000 | 000000 |

| 8,100 | 1/2 | NPT | Female | 6 1/2" | 24" | 1 1/2" | Aluminum | 300 | 7 | 350° | 4 | 0000000 | 000000 |

| 9,600 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 0000000 | 000000 |

| 11,800 | 3/4 | NPT | Female | 12 3/4" | 18" | 1 1/2" | Aluminum | 300 | 19 | 350° | 4 | 0000000 | 000000 |

| 24,000 | 3/4 | NPT | Female | 18 3/4" | 24" | 1 1/2" | Aluminum | 300 | 22 | 350° | 6 | 0000000 | 000000 |

| 31,000 | 1 | NPT | Female | 25" | 24" | 1 1/2" | Aluminum | 300 | 28 | 350° | 8 | 0000000 | 000000 |

| 49,000 | 1 | NPT | Female | 31" | 30" | 1 1/2" | Aluminum | 300 | 30 | 350° | 8 | 0000000 | 000000 |

| 57,000 | 1 1/4 | NPT | Female | 37 7/16" | 30" | 1 1/2" | Aluminum | 300 | 36 | 350° | 8 | 0000000 | 00000000 |

Copper Tube with Bypass—For Use with Oil | |||||||||||||

| 3,400 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 00000000 | 000000 |

| 6,300 | 1/2 | NPT | Female | 6 1/2" | 18 1/4" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 00000000 | 000000 |

| 10,000 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 00000000 | 000000 |

| 12,000 | 3/4 | NPT | Female | 12 3/4" | 18" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 00000000 | 000000 |

| Includes | Each | |

| Two Carriage Bolts, Two Flat Washers, Two Lock Washers, Two Nuts, Two Rubber Blocks | 0000000 | 000000 |

Heat Sinks for Water

A fan cools water as it moves through the tubes to dissipate heat. These heat sinks have flanges with mounting slots for installation in frames and cabinets. Overall height, width, and depth do not include tube ends.

Heat sinks with 316 stainless steel tubes have excellent corrosion resistance to withstand deionized water and other corrosive liquid.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Ht. | Wd. | Dp. | Heat Sink Material | No. of Fans | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | Voltage (Electrical Phase) | Cord Lg., ft. | Mount. Slot Wd. | Tube OD | Choose a Tube Connection Type | Each | |

Copper Tube—For Use With Water | |||||||||||||||

| 1,300 | 6 9/16" | 6 3/4" | 2 13/16" | Copper | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | 00000000 | 0000000 | |

| 1,500 | 5 3/4" | 6 1/2" | 3 5/8" | Copper | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 7/32" | 3/8" | 00000000 | 000000 | |

| 2,200 | 5 3/4" | 11 3/8" | 3 5/16" | Copper | 2 | 150 | 2 | 400° | 120V AC (Single) | 2 | 7/32" | 3/8" | 00000000 | 000000 | |

| 4,200 | 9" | 9 11/16" | 4 1/2" | Copper | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 7/32" | 3/8" | 00000000 | 000000 | |

| 4,400 | 12" | 11 11/16" | 6 1/16" | Copper | 1 | 150 | 4 | 400° | 120V AC (Single) | 2 | 7/32" | 1/2" | 00000000 | 00000000 | |

| 7,100 | 9" | 17 11/16" | 4 1/2" | Copper | 2 | 150 | 2 | 400° | 120V AC (Single) | 2 | 7/32" | 3/8" | 00000000 | 00000000 | |

| 8,800 | 12" | 21 15/16" | 5 5/8" | Copper | 2 | 150 | 4 | 400° | 120V AC (Single) | 2 | 7/32" | 1/2" | 00000000 | 00000000 | |

316 Stainless Steel Tube—For Use With Corrosive Liquid, Deionized Water | |||||||||||||||

| 1,300 | 6 9/16" | 7" | 2 13/16" | Stainless Steel | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | 00000000 | 000000 | |

| 1,500 | 5 13/16" | 6 1/8" | 3 11/16" | Stainless Steel | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | 00000000 | 00000000 | |

| 2,200 | 5 13/16" | 10 7/8" | 3 11/16" | Stainless Steel | 2 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | Plain | 000000000 | 00000000 |

| 4,200 | 9" | 9 3/16" | 4 13/16" | Stainless Steel | 1 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | 00000000 | 00000000 | |

| 4,400 | 12" | 11 3/16" | 6 1/16" | Stainless Steel | 1 | 150 | 4 | 400° | 120V AC (Single) | 2 | 3/16" | 1/2" | Plain | 000000000 | 00000000 |

| 7,100 | 9" | 17 3/16" | 4 1/2" | Stainless Steel | 2 | 150 | 2 | 400° | 120V AC (Single) | 2 | 3/16" | 3/8" | Plain | 000000000 | 00000000 |

| 8,800 | 12" | 21 3/16" | 6 1/16" | Stainless Steel | 2 | 150 | 4 | 400° | 120V AC (Single) | 2 | 3/16" | 1/2" | Plain | 000000000 | 00000000 |

Heat Sinks with Internal Pump for Water

To provide a more consistent flow of cooled water than other heat sinks for water, these have a built-in pump and reservoir. The internal fan-cooled heat exchanger dissipates heat. Btu/hr. cooling capacity is based on water with an initial temperature difference of 77° F.

Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | Voltage (Electrical Phase) | Current | NEMA Style | Cord Lg., ft. | Each | |

For Use with Water, Noncorrosive Liquids | ||||||||||||||||

| 12,000 | 1/2 | NPT | Female | 24" | 15" | 15" | Copper | 60 | 1.8 | 130° | 120V AC (Single) | 5.8A | 5-15 | 8 | 00000000 | 000000000 |

Clamp-On Heat Sinks for Pipe and Tube

Turn your pipe or tube into a heat sink. A hinged design makes these heat sinks simple to wrap around an existing line—no need to cut into your line and drain the liquid to install a heat sink. Multiple fins create a large surface to draw heat away quickly. As they cool down the contents of your line, they heat the space around the heat sink, similar to how radiant heat works.

Secure them together with the included fasteners. You don't need to worry about using heat transfer compounds or putty with these.

Cooling capacity is based on 180° F water flowing through your line at one gallon per minute in a space with an ambient temperature of 65° F and normal airflow.

Overall | 12" Overall Lg. | 24" Overall Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Copper Tube Size | For OD | Ht. | Wd. | Heat Sink Material | Cooling Capacity, Btu/hr. | Each | Cooling Capacity, Btu/hr. | Each | ||

| 1/2 | 5/8" | 2 1/8" | 2 1/8" | Aluminum | 430 | 0000000 | 000000 | 860 | 0000000 | 000000 |

| 3/4 | 7/8" | 2 1/8" | 2 1/8" | Aluminum | 590 | 0000000 | 00000 | 1,100 | 0000000 | 00000 |

| 1 | 1 1/8" | 2 1/8" | 2 1/8" | Aluminum | 1,600 | 0000000 | 00000 | 3,300 | 0000000 | 000000 |

| 1 1/4 | 1 3/8" | 2 1/8" | 2 1/8" | Aluminum | 1,500 | 0000000 | 00000 | 3,000 | 0000000 | 000000 |

Adhesive-Mount Heat Sinks

Remove excess heat by sticking these heat sinks onto circuit boards, semi-conductors, relays, and other heat-sensitive electrical components. They mount using a thermal tape, which makes the heat sink more effective by increasing the heat transfer. The tape also simplifies setup since you don’t need fasteners or to wait for epoxies to cure. Because they're pin style, air can flow around the pins in any direction, which means you get the same heat transfer without needing to determine the airflow direction before mounting.

Thermal resistance is a measure of how difficult it is for a heat sink to transfer heat. The lower the thermal resistance, the more effectively it dissipates heat.

Overall | |||||||

|---|---|---|---|---|---|---|---|

| Ht., mm | Lg., mm | Wd., mm | Thermal Resistance | Heat Sink Material | Includes | Each | |

Pin Style | |||||||

| 9.5 | 15 | 15 | 29.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 9.5 | 17 | 17 | 28° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 19 | 19 | 24° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 21 | 21 | Not Rated | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 23 | 23 | 18° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 25 | 25 | 16.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 27 | 27 | 15.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 29 | 29 | 14.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 30 | 30 | 14° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 35 | 35 | 11.3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 40 | 40 | 10° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 9.5 | 45 | 45 | 9.2° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 15 | 15 | 21.4° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 17 | 17 | 15.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 19 | 19 | 13.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 21 | 21 | 12° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 23 | 23 | 9.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 25 | 25 | 8.8° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 27 | 27 | 8.3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 29 | 29 | 7.8° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 30 | 30 | 7.6° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 14.5 | 35 | 35 | 5.9° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 14.5 | 40 | 40 | 5.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 14.5 | 45 | 45 | 4.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 15 | 15 | 15.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 19.5 | 17 | 17 | 11.3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 0000 |

| 19.5 | 19 | 19 | 9.2° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 21 | 21 | 8.4° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 23 | 23 | 7.8° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 25 | 25 | 6.2° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 27 | 27 | 5.8° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 29 | 29 | 5.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 30 | 30 | 5.3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 35 | 35 | 4.2° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 40 | 40 | 3.6° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 19.5 | 45 | 45 | 3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 15 | 15 | 11.7° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 17 | 17 | 8.6° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 19 | 19 | 7.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 21 | 21 | 6.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 23 | 23 | 6° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 25 | 25 | 4.7° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 27 | 27 | 4.5° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 29 | 29 | 4.2° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 30 | 30 | 4.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 35 | 35 | 3.1° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 40 | 40 | 2.6° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

| 24.5 | 45 | 45 | 2.3° C/W @ 200 LFM | Black Anodized Aluminum | Mounting Tape | 00000000 | 00000 |

Enclosure-Cooling Heat Exchangers

Cool the air in your enclosure to protect electronic components from excessive heat. These heat exchangers absorb heat in the enclosure, then use cooler air outside the enclosure to draw the heat away, lowering the temperature inside. Unlike a fan, they seal out outside air, so dust, moisture, and other contaminants can't get in. Because they use ambient air to cool the enclosure, heat exchangers use less energy and are less likely to cause condensation than air conditioners.

Heat exchangers that meet NEMA 12 and IP54 seal out dust, dirt, and splashing water and oil. Made of steel, these enclosures are powder coated, so they won’t rust in damp environments, but they’re not watertight enough to use outdoors.

NEMA 4- and IP56-rated heat exchangers are designed to withstand rain, snow, and washdowns. They’re made of powder-coated steel.

Heat exchangers rated NEMA 4X and IP56 are made of stainless steel to resist corrosion in the harshest environments. They stand up to weather, washdowns, and corrosive chemicals.

All of these heat exchangers meet American and Canadian safety standards. CE marked heat exchangers also meet European safety standards.

Overall | For Opening | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity, Btu/hr. | Airflow, cfm | Wattage, W | Current, A | Height | Width | Depth | Height | Width | Material | Thermostat Included | For Use Outdoors | Mounting Fasteners Included | Specifications Met | Each | |

NEMA 12, IP54 | |||||||||||||||

120V AC, Single Phase, 60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 000000000 |

| 6,800 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

230V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

460V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | No | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

NEMA 4, IP56 | |||||||||||||||

120V AC, Single Phase, 60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

230V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

460V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Powder-Coated Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

NEMA 4X, IP56 | |||||||||||||||

120V AC, Single Phase, 50Hz/60Hz—Three-Prong Plug | |||||||||||||||

| 1,400 | Not Rated | 80 | 0.7 | 12" | 12" | 8" | 11" | 11" | Stainless Steel | No | Yes | Yes | UL Listed C-UL Listed CE Marked | 0000000 | 00000000 |

| 3,000 | Not Rated | 160 | 1.4 | 23" | 12" | 8" | 21 3/4" | 11" | Stainless Steel | No | Yes | Yes | UL Listed C-UL Listed CE Marked | 0000000 | 00000000 |

120V AC, Single Phase, 60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

230V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

460V AC, Single Phase, 50Hz/60Hz—Screw Terminals | |||||||||||||||

| 4,400 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 6,800 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 10,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |

| 12,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 |