How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

How to Install Key-Locking Inserts

More

About Hose

More

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance. BSPP and metric male threads have either a gasket or a gasket and washer to prevent leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have a gasket to prevent leaks.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

UN/UNF (SAE Straight)

Male Threads with Gasket

- Specifications Met: See table

- For Use With: See table

316 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Thread Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | For Use With | Specifications Met | Each | |

NPT Female × Metric Male | |||||||||

| 3/8 | __ | 06 | M18 × 1.5 mm | __ | 4,500 psi @ 72° F | Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 9974 | 00000000 | 000000 |

| 1/2 | __ | 08 | M18 × 1.5 mm | __ | 4,000 psi @ 72° F | Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 9974 | 00000000 | 00000 |

Metric Female × UN/UNF (SAE Straight) Male | |||||||||

| __ | M18 × 1.5 mm | __ | 3/4"-16 | 08 | 6,000 psi @ 72° F | Hydraulic Fluid (Petroleum Base), Oil, Water | __ | 000000000 | 00000 |

UN/UNF (SAE Straight) Female × Metric Male | |||||||||

| __ | 3/4"-16 | 08 | M18 × 1.5 mm | __ | 3,500 psi @ 72° F | Hydraulic Fluid (Petroleum Base), Oil, Water | __ | 000000000 | 00000 |

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

316 Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Max. Pressure | For Use With | Specifications Met | Each | |

BSPP Male × Metric Male | |||||||

| 1/2 | 08 | M18 × 1.5 mm | 4,500 psi @ 72° F | Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 8434-6, ISO 9974 | 00000000 | 000000 |

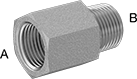

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized and zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

For technical drawings and 3-D models, click on a part number.

- For Use With:

NPTF: Air, Hydraulic Fluid, Water

Metric: Air, Hydraulic Fluid, Oil, Water - Specifications Met:

NPTF: ASTM A108

Metric: DIN 7631, ISO 6149, ISO 9974

| Thread Size | Max. Pressure | Material | Each | |

Metric Female | ||||

|---|---|---|---|---|

| M18 × 1.5 mm | 4,000 psi @ 72° F | Galvanized Steel | 00000000 | 000000 |

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Thread Size (A) | Dash Size (A) | Pipe Size (B) | Thread Size (B) | Dash Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPT Female × Metric Male | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8 | __ | 06 | __ | M18 × 1.5 mm | __ | 4,000 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 2353, ISO 8434-1 | 00000000 | 00000 |

| 1/2 | __ | 08 | __ | M18 × 1.5 mm | __ | 3,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 2353, ISO 8434-1 | 00000000 | 0000 |

Metric Female × NPT Male | |||||||||||

| __ | M18 × 1.5 mm | __ | 3/8 | __ | 06 | 5,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 6149, ISO 9974 | 00000000 | 00000 |

| __ | M18 × 1.5 mm | __ | 1/2 | __ | 08 | 4,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 6149, ISO 9974 | 00000000 | 00000 |

(SAE Straight) Male Threads

with Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPT Male × Metric Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/8 | 06 | M18 × 1.5 mm | 5,500 psi @ 72° F | Galvanized Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 2353, ISO 8434-1 | 00000000 | 000000 |

BSPP Male × Metric Male | ||||||||

| 1/2 | 08 | M18 × 1.5 mm | 4,500 psi @ 72° F | Galvanized Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 1179, ISO 6149, ISO 8434-6, ISO 9974 | 00000000 | 00000 |

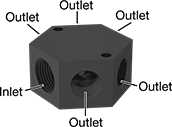

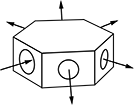

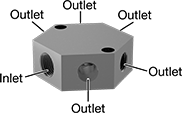

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Color | Each | |

| 5 | M20 | 1.5 | M18 | 1.5 | 50 | 31 | Standard | Black | 00000000 | 0000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Each | |

| 5 | M20 | 1.5 | M18 | 1.5 | 50 | 31 | Standard | 00000000 | 0000000 |

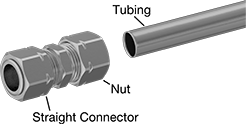

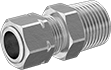

Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: See Table

- Tubing: Use with copper

- Specifications Met: See Table

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Thread Size | Thread Pitch, mm | Material | Max. Pressure | Temp. Range, °F | Each | |

Metric Threads | ||||||||

| 10mm | 1mm | M18 | 1.5 | Brass | 1,080 psi @ 72° F | -40° to 250° | 00000000 | 000000 |

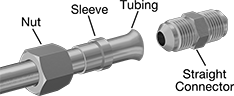

37° Flared Fittings for Steel Tubing

Male Threads with

Gasket and Washer

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

- Temperature Range: See table

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Gasket Material | Washer Material | Max. Pressure | Temp. Range, °F | Each | |

Metric Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | M18 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | __ | 2,300 psi @ 72° F | -30° to 200° | 00000000 | 000000 |

| 1/2" | M18 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | Zinc-Plated Steel | 4,500 psi @ 72° F | -20° to 212° | 00000000 | 00000 |

| 5/8" | M18 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | __ | 2,300 psi @ 72° F | -30° to 200° | 00000000 | 00000 |

- Temperature Range: NPT: -65° to 400° F

NPTF and BSPT: -60° to 400° F

Metric and BSPP with O-Rings: -30° to 200°F

BSPP with Washers: -20° to 212° F

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

For Tube OD | |||||

|---|---|---|---|---|---|

| Inch | Metric, mm | Sleeve Material | Max. Pressure | Each | |

Inch Sleeves | |||||

| 1/2" | __ | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 00000 |

| 5/8" | __ | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

Inch × Metric Sleeve Adapters | |||||

| 1/2" | 12 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | 14 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | 16 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

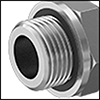

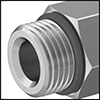

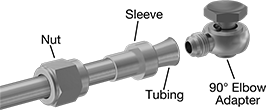

Tight-Space 37° Flared Fittings for Steel Tubing

- Temperature Range: -20° to 212° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

The external hex bolt on these fittings allows for easy installation in cramped spaces. Fittings are also known as banjo-style fittings and JIC (Joint Industrial Council) fittings. They provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings are zinc-plated steel, which has fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Washer Material | Max. Pressure | Each | |

Metric Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2" | M18 | 1.5 | Zinc-Plated Steel | Copper | 3,000 psi @ 72° F | 00000000 | 000000 |

Plastic Barbed Tube Fittings for Air and Water

Fittings have barbs that grip onto tubing.

Nylon fittings have excellent impact and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: See table

- Tubing: Semi-Clear: Use with firm or soft (Durometer 45A-80A) polyurethane rubber or PVC plastic

Opaque: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Metric Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 12mm | M18 × 1.5 mm | Nylon Plastic | Gray | Opaque | 145 psi @ 72° F | -40° to 190° | 10 | 00000000 | 000000 |

- Temperature Range: See table

- Tubing: Semi-Clear: Use with firm or soft (Durometer 45A-80A) polyurethane rubber or PVC plastic

Opaque: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance.Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance.

Stainless steel fittings have very good corrosion resistance. 303 stainless steel fittings won’t rust when exposed to water, making them good for areas that require frequent cleanings. Fittings with a threaded end are also known as hose nipples.

Metric, UN/UNF (SAE Straight), and BSPP male threads with gasket protect against leaks.

For technical drawings and 3-D models, click on a part number.

UN/UNF (SAE Straight)

Male Threads with Gasket

- Maximum Pressure: See table

- Maximum Vacuum: 27 in. of Hg @ 72° F

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Thread Size | Gasket Material | Max. Pressure | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | M18 × 1.5 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

| 3/4" | M18 × 1.5 mm | Buna-N Rubber | 300 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

Aluminum | ||||||||

| 1/2" | M18 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

303 Stainless Steel | ||||||||

| 1/2" | M18 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

| 3/4" | M18 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

| 19mm | M18 × 1.5 mm | Buna-N Rubber | 125 psi @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

Push-On Barbed Hose Fittings for Hydraulic Fluid

These fittings have sharp barbs to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip. Use them in low-pressure hydraulic applications up to 350 psi. Also known as hose nipples, they adapt a barbed end to a threaded end, so you can connect to pumps, cylinders, and other equipment in your hydraulic system. Fittings are zinc-plated steel, which has excellent strength and durability. Fittings have fair corrosion resistance.

Fittings that swivel until tightened rotate 360° for easy installation.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 350 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

- Maximum Pressure: See table

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

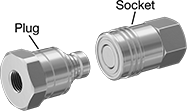

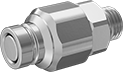

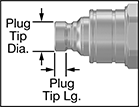

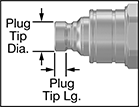

International Standard ISO Minimal-Spill

Quick-Disconnect Hose Couplings for Hydraulic Fluid

Also known as flush-face couplings, the plugs and sockets have a flat face, which allows them to mate close against each other, reducing fluid loss when connecting and disconnecting the line. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them when you need frequent access to a line. All of the International Standard ISO Minimal-Spill quick-disconnect plugs are compatible with any of the International Standard ISO Minimal-Spill quick-disconnect sockets of the same coupling size, regardless of the pipe size. Also known as double shut-off couplings, the plugs and sockets both have a shut-off valve that stops the flow when the coupling is separated. They are zinc-plated steel, which has excellent strength and durability and fair corrosion resistance.

Plugs are also known as nipples.

Sockets are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Never attempt to connect or disconnect couplings when operating at maximum pressure. Stop the flow before you disconnect the line.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -20° to 212° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

- Maximum Pressure: 5,800 psi @ 72° F

- Temperature Range: -20° to 212° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

Black-Phosphate Steel Easy-to-Install Thread-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Also known as E-Z Lok, these inserts use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. Installation requires a drill bit and a standard tap. Then set the insert with a bolt and two nuts, or use an installation bit.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For technical drawings and 3-D models, click on a part number.

For Tap | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Pkg. Qty. | Pkg. | |

Black-Phosphate Steel with Thick Wall | |||||||||

| M18 | 1.5 | Fine | 1"-12 | 29/64" | 59/64" | 59/64" | 1 | 000000000 | 00000 |

18-8 Stainless Steel Key-Locking Inserts

Made of stainless steel, these inserts have good corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For technical drawings and 3-D models, click on a part number.

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

For technical drawings and 3-D models, click on a part number.

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

18-8 stainless steel inserts are more corrosion resistant than black-phosphate steel. They may be mildly magnetic.

Black-phosphate steel inserts are mildly corrosion resistant.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For technical drawings and 3-D models, click on a part number.

For Tap | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

18-8 Stainless Steel with Thick Wall | |||||||||||

| M18 | 1.5 | Fine | M24 | 1.5 | 24mm | 22.5 mm | 22.5mm | 4 | 2 | 000000000 | 000000 |

Black-Phosphate Steel with Thick Wall | |||||||||||

| M18 | 1.5 | Fine | M24 | 1.5 | 24mm | 22.5 mm | 22.5mm | 4 | 2 | 000000000 | 00000 |