H Series Timing Belts

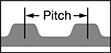

Good for use in general purpose drive systems, these belts combine quiet-running neoprene with high-strength fiberglass reinforcement. They are H series (heavy) and have trapezoidal teeth. The teeth are nylon coated to protect the wear surface and minimize friction.

For technical drawings and 3-D models, click on a part number.

| Belt Trade Number | Outer Circle | Number of Teeth | Pitch | Material | Color | Temperature Range, ° F | Each | |

3/4" Wd. | ||||||||

|---|---|---|---|---|---|---|---|---|

| 480H075 | 48" | 96 | 0.500" | Neoprene | Black | -30° to 180° | 0000000 | 000000 |

1" Wd. | ||||||||

| 480H100 | 48" | 96 | 0.500" | Neoprene | Black | -30° to 180° | 00000000 | 00000 |

1 1/2" Wd. | ||||||||

| 480H150 | 48" | 96 | 0.500" | Neoprene | Black | -30° to 180° | 00000000 | 00000 |

2" Wd. | ||||||||

| 480H200 | 48" | 96 | 0.500" | Neoprene | Black | -30° to 180° | 00000000 | 000000 |

H Series Dust-Free Timing Belts

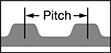

Urethane has excellent abrasion resistance, so these belts don’t create dust while they run. Belts have steel reinforcement, which has very high strength, low stretch, and excellent shock resistance. All are H series (heavy) and have trapezoidal teeth.

For technical drawings and 3-D models, click on a part number.

High-Strength HTD Timing Belts

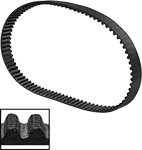

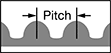

HTD (high torque drive) timing belts have a curved tooth shape that provides higher strength than trapezoidal teeth. Belts are neoprene with fiberglass reinforcement for quiet operation. The teeth are nylon coated to protect the wear surface and minimize friction.

For technical drawings and 3-D models, click on a part number.

| Belt Trade Number | Manufacturer Equivalent Number | Outer Circle, mm | Number of Teeth | Pitch, mm | Material | Color | Temperature Range, °F | Specifications Met | Each | |

20 mm Wd. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 480-H8M-20 | Omega High Power | 480 | 60 | 8 | Neoprene | Black | -20° to 212° | ISO 9563 | 00000000 | 000000 |