About Plastic

More

Print Surfaces for 3D Printers

Also known as build sheets, stick these sheets to your printer bed for more accurate 3D printed parts than those made on bare printer beds, masking tape, and glue. They won’t transfer heat between your part and printer bed, which means they grip your part as it prints to keep it from shifting. Then they easily release the part without damaging it once it’s cooled. Because they’re insulating, they also protect glass printer beds from cracking due to sudden temperature changes, so you won’t need to replace the bed as often. You can reuse these sheets multiple times, since they’re durable and stand up to heat.

Use these sheets with fused filament fabrication (FFF) 3D printers. Cut them to size with scissors before sticking them to your printer bed. For large print surfaces, use primer and smoothing tools (both sold separately) to remove wrinkles and trapped air bubbles.

Plastic-blend print surfaces have a stronger hold than PEI print surfaces, so they’re good for polycarbonate and other filaments that are prone to warping. But, this makes them difficult for removing some polyester-based filaments. Since they’re coarse, they leave a textured finish on the bottom of your part.

PEI print surfaces don’t grip as tightly as plastic-blend print surfaces, making them easier for removing sticky filaments, such as PETG. They also last longer. Their smooth exterior leaves a smooth finish on the bottom of your part.

For technical drawings and 3-D models, click on a part number.

| Lg. | Wd. | Thick. | For Printer Bed Temp. | Color | Each | |

Plastic Blend—For Heated and Unheated Printer Beds | ||||||

|---|---|---|---|---|---|---|

| 4 1/2" | 4 1/2" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 6 5/16" | 5 1/8" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 0000 |

| 6 1/2" | 6 1/2" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 0000 |

| 8" | 8" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 8 7/8" | 8 7/8" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 9 1/4" | 6 1/4" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 10" | 6 1/2" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 10" | 8" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 10" | 9" | 0.014" | 21° to 120° C 70° to 248° F | Black | 000000 | 00000 |

| 10" | 9 1/2" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 10" | 10" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 11 1/2" | 6 1/2" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 12" | 12" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 16" | 16" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

| 19 7/8" | 19 7/8" | 0.014" | 21° to 120° C 70° to 248° F | Black | 0000000 | 00000 |

PEI Plastic—For Heated and Unheated Printer Beds | ||||||

| 6 5/16" | 5 1/8" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 0000 |

| 6 1/2" | 6 1/2" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 8" | 8" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 8 7/8" | 8 7/8" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 9 1/4" | 6 1/4" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 10" | 6 1/2" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 000000 | 00000 |

| 10" | 8" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 10" | 9" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 10" | 9 1/2" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 10" | 10" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 12" | 12" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 16" | 16" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

| 19 7/8" | 19 7/8" | 0.014" | 21° to 150° C 70° to 302° F | Amber | 0000000 | 00000 |

Filament 3D Printers

Melt and extrude plastic filaments to build quick and inexpensive prototypes, custom and complex parts, and manufacturing aids such as jigs and fixtures. These 3D printers are also known as fused filament fabrication (FFF) and fused deposition modeling (FDM) printers. They meet U.S. and international standards for safety. Product regulations restrict sales to the listed jurisdictions/areas.

These printers use PLA, which is good for creating prototypes. PLA prints at a low temperature, so it rarely clogs extruders. Because it’s so low maintenance, it’s the most common material for 3D printing. MakerBot printers are compatible only with MakerBot-brand filaments.

These printers have a camera that connects to the internet, so you can stream live video of the printing process to monitor it remotely. They have heated printer beds to prevent parts from warping during cooling.

Max. Printing | Printer Bed | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Min. Layer Ht., mm | Printer Speed, mm/s | Material | Type | Lg. | Wd. | Ht. | Accuracy, mm | Data Connection Type | Current, A | Voltage | Specifications Met | Cannot Be Sold To | Each | |

Sketch Large | |||||||||||||||||

| 8.7" | 7.9" | 9.84" | 0.1 | 150 | Steel | Heated | 18 1/2" | 21.07" | 21.54" | Not Rated | Ethernet, USB-A, Wi-Fi | 2.7 | 120V AC, 240V AC | C-UL Listed, CE Marked, UL-Listed | Outside United States and Canada | 0000000 | 000000000 |

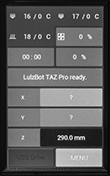

LulzBot printers are compatible with many different materials, so they’re useful across a wide range of applications. They have a minimum layer height that is twice as thin as MakerBot printers, meaning they print a finer level of detail. LulzBot printers come with open source software, so you can manually adjust temperature and print settings. All have heated printer beds to prevent parts from warping during cooling. The printer beds are reversible—prints adhere well to the PEI glass side, while the borosilicate glass side is especially flat for perfectly level prints.

Mini 2 printers are the smallest in our offering but also among the fastest; use them to quickly print small pieces.

TAZ Workhorse printers have the best combination of size and speed in our offering. They’re as fast as Mini 2 printers with a print area as large as TAZ Pro printers.

TAZ Pro printers are not as fast as the Mini 2 or the Workhorse, but have dual extruders so you can print structural supports. Dual extruders can also print two different colors into a single part.

Max. Printing | Printer Bed | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Min. Layer Ht., mm | Printer Speed, mm/s | Material | Type | Lg. | Wd. | Ht. | Accuracy, mm | Data Connection Type | Current, A | Voltage | Specifications Met | Each | |

Mini 2 | ||||||||||||||||

| 6 1/4" | 6 1/4" | 7" | 0.05 | 300 | Borosilicate Glass PEI Glass | Heated | 18" | 13" | 24" | ±0.2 | Standard SD Card, USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 000000000 |

TAZ Workhorse | ||||||||||||||||

| 11" | 11" | 11 1/8" | 0.05 | 300 | Borosilicate Glass PEI Glass | Heated | 32 3/4" | 20" | 20 1/2" | ±0.2 | Standard SD Card, USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 00000000 |

TAZ Pro | ||||||||||||||||

| 11" | 11" | 11 1/8" | 0.05 | 200 | Borosilicate Glass PEI Glass | Heated | 32 5/8" | 28" | 20 1/2" | ±0.2 | USB-A | 3.2 | 120V AC, 240V AC | UL Listed, ETL Listed, C-ETL Listed, OSHW Certified, CSA Certified, CE Marked | 0000000 | 00000000 |

Clear Slippery High-Temperature FEP Film

The slippery surface on this FEP film prevents sticking. Use it as a release film when making molded parts.

For technical drawings and 3-D models, click on a part number.

- Color: Clear

- Temperature Range: -320° to 400° F

- Tensile Strength: 3,000-3,500 psi (Poor)

- Impact Strength: No Break (Excellent)

- Hardness: Rockwell R25 (Medium Soft)

- For Use Outdoors: Yes

- Specifications Met: UL 94 V-0

- Color: Clear

- Temperature Range: -100° to 400° F

- Tensile Strength: 3,000-3,500 psi (Poor)

- Impact Strength: No Break (Excellent)

- Hardness: Rockwell R25 (Medium Soft)

- For Use Outdoors: No

12" × 12" | |||||

|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Adhesive Type | Adhesive Temperature, °F | Each | |

| 0.0035" | -0.0004" to 0.0004" | Silicone | -100° to 400° | 0000000 | 000000 |

Electrical-Insulating Ultem PEI Film

Use this film in 3D printing operations as a build surface. It’s also widely used in semiconductor applications because it has excellent electrical-insulating properties.

For technical drawings and 3-D models, click on a part number.

- Color: Semi-Clear Amber

- Temperature Range: -20° to 335° F

- Tensile Strength: 14,200 psi (Excellent)

- Impact Strength: Not Rated

- Hardness: Rockwell M109 (Extra Hard)

- For Use Outdoors: Yes

- Specifications Met: UL 94 VTM-0

12" × 12" | 12" × 24" | |||||

|---|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Dielectric Strength | Each | Each | ||

| 0.001" | -0.0001" to 0.0001" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 000000 |

| 0.002" | -0.0002" to 0.0002" | 3,050 V/mil | 0000000 | 0000 | 0000000 | 00000 |

| 0.003" | -0.0003" to 0.0003" | 3,050 V/mil | 0000000 | 0000 | 0000000 | 00000 |

| 0.005" | -0.0005" to 0.0005" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.01" | -0.001" to 0.001" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.02" | -0.002" to 0.002" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.03" | -0.003" to 0.003" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

- Color: Semi-Clear Amber

- Temperature Range: -20° to 335° F

- Tensile Strength: 14,200 psi (Excellent)

- Impact Strength: Not Rated

- Hardness: Rockwell M109 (Extra Hard)

- For Use Outdoors: Yes

12" × 12" | 12" × 24" | |||||

|---|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Dielectric Strength | Each | Each | ||

| 0.001" | -0.0001" to 0.0001" | 3,050 V/mil | 0000000 | 000000 | 0000000 | 000000 |

| 0.002" | -0.0002" to 0.0002" | 3,050 V/mil | 0000000 | 00000 | 000000 | 00 |

| 0.003" | -0.0003" to 0.0003" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.005" | -0.0005" to 0.0005" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.01" | -0.001" to 0.001" | 3,050 V/mil | 0000000 | 00000 | 0000000 | 00000 |

| 0.02" | -0.002" to 0.002" | 3,050 V/mil | 0000000 | 00000 | 000000 | 00 |

| 0.03" | -0.003" to 0.003" | 3,050 V/mil | 0000000 | 00000 | 000000 | 00 |