About Roller Chain and Sprockets

More

Grade 30 Chain—Not for Lifting

Use this strong chain for binding loads, tie downs, and towing applications. It is stamped with the grade and manufacturer. When using fittings with chain, you must match the trade size and meet or exceed the chain’s grade. Galvanized steel chain has excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straight-Link Chain Trade Size | Metric Trade Size | Thick. | Wd. | Lg. | Cap., lbs. | Wt. per ft., lbs. | Approximate No. of Links per ft. | For Fitting Thick. | Max. Temp., ° F | For Use Outdoors | Lengths, ft. | Per Ft. | |

Unfinished Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 1.00" | 1.87" | 6,900 | 4 | 6 | 15/16" | 400º | No | 0000000 | 000000 | |

Galvanized Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 1.00" | 1.87" | 6,900 | 4 | 6 | 15/16" | 400º | Yes | 0000000 | 00000 | |

High-Strength Grade 43 Chain—Not for Lifting

This chain is approximately 50% stronger than Grade 30 chain. Use it for binding loads, tie downs, and towing applications. It is stamped with the grade and manufacturer. When using fittings with chain, you must match the trade size and meet or exceed the chain’s grade. Galvanized steel chain has excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straight-Link Chain Trade Size | Metric Trade Size | Thick. | Wd. | Lg. | Cap., lbs. | Wt. per ft., lbs. | Approximate No. of Links per ft. | For Fitting Thick. | Max. Temp., ° F | For Use Outdoors | Lengths, ft. | Per Ft. | |

Unfinished Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 0.85" | 2.02" | 13,000 | 3.8 | 6 | 13/16" | 400° | No | 0000000 | 000000 | |

Galvanized Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 1.00" | 1.87" | 13,000 | 4 | 6 | 15/16" | 400° | Yes | 0000000 | 00000 | |

Jack Chain—Not for Lifting

The links are formed into a figure eight then twisted into a 90° angle for a lightweight chain suitable for hanging applications.

Zinc-plated steel chain has good corrosion resistance. Nickel-plated steel, brass-plated steel, and brass chain have excellent corrosion resistance. 304 stainless steel chain is the most corrosion resistant.

For a comparison of chain sizes, view our sizing guide.

For technical drawings and 3-D models, click on a part number.

| Jack Chain Trade Size | Thick. | Inside Lg. | Cap., lbs. | For Use Outdoors | Lengths, ft. | Per Ft. | |

Zinc-Plated Steel | |||||||

|---|---|---|---|---|---|---|---|

| 16 | 0.06" | 0.52" | 10 | No | 0000000 | 00000 | |

Nickel-Plated Steel | |||||||

| 16 | 0.06" | 0.52" | 10 | No | 0000000 | 000 | |

Brass-Plated Steel | |||||||

| 16 | 0.06" | 0.52" | 10 | No | 0000000 | 000 | |

Unfinished Brass | |||||||

| 16 | 0.06" | 0.52" | 8 | No | 00000000 | 0000 | |

Unfinished 304 Stainless Steel | |||||||

| 16 | 0.06" | 0.52" | 10 | Yes | 000000 | 0000 | |

Sash Chain Lanyards—Not for Lifting

The chain has flat links that fold back on themselves for maximum flexibility. Use the split ring on one end to hold tags and keys.

Zinc-plated steel lanyards are mildly corrosion resistant.

| Lg. | Thick. | Sash Chain Trade Size | Split Ring Dia. | Each | |

Zinc-Plated Steel | |||||

|---|---|---|---|---|---|

| 16" | 1/32" | 8 | 5/8" | 000000000 | 00000 |

General Purpose Grade 80 Chain—For Lifting

Strong and durable, use this chain for your lifting applications. It is heat treated and stamped with the grade and manufacturer. When using fittings with chain, you must match the trade size and meet or exceed the chain’s grade.

Zinc-plated steel chain has good corrosion resistance.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straight-Link Chain Trade Size | Metric Trade Size | Thick. | Wd. | Lg. | Cap., lbs. | Wt. per ft., lbs. | Approximate No. of Links per ft. | For Fitting Thick. | Max. Temp., ° F | For Use Outdoors | Lengths, ft. | Per Ft. | |

Black Painted Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 0.92" | 1.93" | 18,100 | 3.7 | 6 | 7/8" | 400° | No | 0000000 | 000000 | |

Zinc-Plated Steel | |||||||||||||

| 5/8 | 16 | 0.61" | 0.87" | 1.89" | 18,100 | 3.8 | 8 | 13/16" | 400° | No | 0000000 | 00000 | |

Gauge measures the maximum allowable wear tolerances on links of Grade 80 or Grade 100 steel chain, as required by OSHA. If the gauge can be inserted over any part of the link, the chain should be taken out of service.

High-Strength Grade 100 Chain—For Lifting

This chain is approximately 25% stronger than Grade 80 chain. It's heat treated and stamped with the grade and manufacturer. When using fittings with chain, you must match the trade size and meet or exceed the chain’s grade.

Zinc-plated steel chain has good corrosion resistance.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straight-Link Chain Trade Size | Metric Trade Size | Thick. | Wd. | Lg. | Cap., lbs. | Wt. per ft., lbs. | Approximate No. of Links per ft. | For Fitting Thick. | Max. Temp., ° F | For Use Outdoors | Lengths, ft. | Per Ft. | |

Unfinished Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 0.85" | 1.89" | 22,600 | 3.9 | 6 | 13/16" | 400° | No | 0000000 | 000000 | |

Black Zinc-Plated Steel | |||||||||||||

| 5/8 | 16 | 0.63" | 0.85" | 1.89" | 22,600 | 3.9 | 6 | 13/16" | 400° | No | 0000000 | 00000 | |

Gauge measures the maximum allowable wear tolerances on links of Grade 80 or Grade 100 steel chain, as required by OSHA. If the gauge can be inserted over any part of the link, the chain should be taken out of service.

| For Straight-Link Chain Trade Size | For Manufacturer Model Number | Each | |

For Grade 80 and Grade 100 Chain | |||

|---|---|---|---|

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | L8, L10 | 00000000 | 000000 |

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | P8, P10, H29, KWB | 00000000 | 00000 |

For Grade 100 Chain | |||

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | C10 | 0000000 | 00000 |

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | PW, PWA | 00000000 | 00000 |

Metric Roller Chain and Links

This chain conforms to ISO 606B and is compatible with BS 228 (British standard) and DIN 8187 (German standard).

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding-and-connecting links are also known as half links and offset links. They can join chain that requires an odd number of links. For trade number 06B and up, the side plate is easy to remove for attaching them to chain.

For technical drawings and 3-D models, click on a part number.

Pitch | ||||||||

|---|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Lengths, ft. | Per Ft. | |

Steel | ||||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 1-20, 50, 100 | 0000000 | 000000 |

Pitch | |||||||

|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Each | |

Steel | |||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 0000000 | 00000 |

Pitch | |||||||

|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Each | |

Steel | |||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 0000000 | 00000 |

Corrosion-Resistant Metric Roller Chain and Links

Made of stainless steel, this chain has excellent corrosion resistance. It conforms to ISO 606B and is compatible with BS 228 (British standard) and DIN 8187 (German standard).

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding-and-connecting links are also known as half links and offset links. They can join chain that requires an odd number of links. For trade number 06B and up, the side plate is easy to remove for attaching them to chain.

For technical drawings and 3-D models, click on a part number.

High-Strength Corrosion-Resistant Metric Roller Chain and Links

This treated steel chain has over seven times the capacity of stainless steel chain. It conforms to ISO 606B and is compatible with BS 228 (British standard) and DIN 8187 (German standard).

Connecting links are also known as master links. They're used to join the ends of a chain length. The side plate is easy to remove for attaching to a chain. Adding-and-connecting links are also known as half links and offset links. They can join chain that requires an odd number of links. The side plate is easy to remove for attaching to chain.

For technical drawings and 3-D models, click on a part number.

Pitch | ||||||||

|---|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Length, ft. | Per Ft. | |

Corrosion-Resistant-Coated Steel | ||||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 1, 10, 20, 50, 100 | 000000 | 000000 |

Pitch | |||||||

|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Each | |

Corrosion-Resistant-Coated Steel | |||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 00000000 | 00000 |

Pitch | |||||||

|---|---|---|---|---|---|---|---|

| Roller Chain Trade No. | mm | in. | Roller Dia., mm | Roller Wd., mm | Working Load, lbs. | Each | |

Corrosion-Resistant-Coated Steel | |||||||

| 16B | 25.40 | 1.000" | 15.88 | 17.02 | 3,600 | 00000000 | 000000 |

High-Accuracy Roller Chain Wear-Indicating Gauges

Precisely measure chain elongation to see if you need to replace your chain. These gauges give a more accurate reading than alternatives because they’re designed to anchor to a roller and extend across several links. A color indicator helps you quickly measure the space between rollers. If the gauge rests on top of the chain and you see green markings, your chain doesn't need to be replaced. If it slips between two rollers and you only see red markings, it’s time for a replacement.

| For Roller Chain Trade Size | Material | Each | |

For Single-, Double-, and Triple-Strand ISO Roller Chain | |||

|---|---|---|---|

| 16B | Steel | 0000000 | 0000000 |

| No. of Gauges | For Roller Chain Trade Size | Material | Includes | Each | |

For Single-, Double-, and Triple-Strand ISO Roller Chain | |||||

|---|---|---|---|---|---|

| 5 | 06B, 08B, 10B, 12B, 16B | Steel | Chain Indentification Tool | 0000000 | 000000000 |

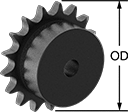

Sprockets for Metric Roller Chain

Designed to meet ISO 606 and DIN 8187 international dimensional standards, these sprockets are for use with compatible ISO and DIN roller chain. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 16B Roller Chain (25.4 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 12 | 16 | 47 | 114.01 | 40 | 72 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 15 | 16 | 62 | 138.04 | 40 | 96 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 17 | 25 | 67 | 154.11 | 45 | 102 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 20 | 25 | 70 | 178.24 | 45 | 108 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

Idler Sprockets for Metric Roller Chain

Keep constant tension on your drive with these sprockets that press against your metric ISO roller chain to take up slack and reduce wear and vibration. They rotate freely on built-in ball bearings, which are double sealed to keep dirt out, and are for use with roller chain tensioners. All come with a finished bore that fits directly onto your shaft—no need for machining. These sprockets meet ISO 606, which is an international standard for dimensions and materials.

For technical drawings and 3-D models, click on a part number.

Bearing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Type | Material | Specifications Met | Each | |

For ISO 16B Roller Chain (25.4 mm Pitch) | ||||||||||

| 12 | 20 | 109 | 18 | 47 | Steel | Ball | Steel | ISO 606 | 000000 | 000000 |

Roller Chain Tensioning Rings

Install these rings between strands of chain to absorb slack without the need for realignment, lubrication, or tools—good for use in confined spaces where maintenance may be difficult.

For technical drawings and 3-D models, click on a part number.

| For Roller Chain Trade Size | Tension Force, lbs. | OD | Max. Speed, fpm | Maximum Temperature, ° F | Material | Each | |

For Single-Strand ANSI, ISO Roller Chain | |||||||

|---|---|---|---|---|---|---|---|

| 80, 16B | 21 | 8.15" | 1,120 | 155° | Plastic | 000000 | 0000000 |