Ultra-High-Strength Poly Chain Timing Belts

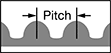

Strong enough to replace roller chain, these timing belts combine the high strength of a curved tooth with high-strength carbon fiber reinforcement. Belts are abrasion-resistant urethane, so they don’t create dust while they run. They have carbon fiber reinforcement, which has ultra-high-strength, low stretch, and excellent shock resistance. The teeth are nylon coated to protect the wear surface and minimize friction.

For technical drawings and 3-D models, click on a part number.