Choose a magnet with the right strength, material, and temperature resistance for your application.

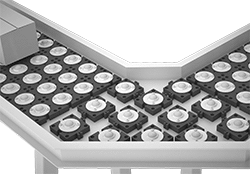

Create-Your-Own Ball Transfer Plates

Snap these ball transfers together like jigsaw pieces to create a custom ball transfer plate, or use them unconnected to create your own pattern for rotating and positioning material. They have magnets embedded in the frame, so you can mount them on any flat magnetic metal surface and rearrange them as your operations change.

Neodymium Magnets

Made of neodymium, these rare earth magnets are the strongest for their size. The nickel-plated finish resists corrosion.

Warning: Maximum pull ratings are based on direct contact with rust-free and unpainted iron plate. Variations in material condition will significantly reduce these ratings. Do not use for lifting over people.