About Installing Blind Rivets

More

18-8 Stainless Steel Domed Head High-Strength Blind Rivets

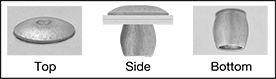

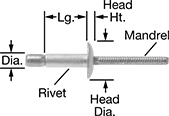

18-8 stainless steel has good corrosion resistance and may be mildly magnetic. The mandrel expands the body of these rivets to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

1/8" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.063"-0.125" | 0.275" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 700 | 600 | IFI 119 Standards | 10 | 000000000 | 000000 |

| 0.126"-0.25" | 0.4" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 700 | 600 | __ | 10 | 000000000 | 0000 |

| 0.188"-0.312" | 0.462" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 700 | 600 | __ | 10 | 000000000 | 0000 |

| 0.251"-0.375" | 0.535" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 700 | 600 | __ | 10 | 000000000 | 0000 |

5/32" Dia. | |||||||||||

| 0.126"-0.25" | 0.425" | 0.16"-0.164" | No. 20 | 0.312" | 0.05" | 1,050 | 1,000 | IFI 119 Standards | 5 | 000000000 | 0000 |

| 0.251"-0.375" | 0.55" | 0.16"-0.164" | No. 20 | 0.312" | 0.05" | 1,050 | 1,000 | IFI 119 Standards | 5 | 000000000 | 00000 |

3/16" Dia. | |||||||||||

| 0.126"-0.25" | 0.45" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,650 | 1,300 | __ | 10 | 000000000 | 00000 |

| 0.251"-0.375" | 0.575" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,650 | 1,300 | __ | 5 | 000000000 | 0000 |

| 0.376"-0.5" | 0.7" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,650 | 1,300 | __ | 5 | 000000000 | 00000 |

1/4" Dia. | |||||||||||

| 0.126"-0.25" | 0.5" | 0.257"-0.261" | F | 0.5" | 0.08" | 2,450 | 2,250 | __ | 5 | 000000000 | 00000 |

| 0.251"-0.375" | 0.625" | 0.257"-0.261" | F | 0.5" | 0.08" | 2,450 | 2,250 | __ | 1 | 000000000 | 0000 |

| 0.376"-0.5" | 0.75" | 0.257"-0.261" | F | 0.5" | 0.08" | 2,450 | 2,250 | __ | 1 | 000000000 | 0000 |

Zinc-Plated Steel Domed Head High-Strength Blind Rivets

The zinc-plated finish on these rivets provides mild corrosion resistance. The mandrel expands the body of these rivets to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Pkg. Qty. | Pkg. | |

1/8" Dia. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.094"-0.187" | 0.337" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 500 | 400 | 25 | 000000000 | 00000 |

| 0.126"-0.25" | 0.4" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 500 | 400 | 25 | 000000000 | 0000 |

| 0.188"-0.312" | 0.462" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 500 | 400 | 25 | 000000000 | 00000 |

| 0.251"-0.375" | 0.535" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 500 | 400 | 25 | 000000000 | 00000 |

| 0.376"-0.5" | 0.67" | 0.129"-0.133" | No. 30 | 0.25" | 0.04" | 500 | 400 | 25 | 000000000 | 00000 |

3/16" Dia. | ||||||||||

| 0.062"-0.125" | 0.325" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,050 | 820 | 25 | 000000000 | 00000 |

| 0.126"-0.25" | 0.45" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,050 | 820 | 25 | 000000000 | 00000 |

| 0.251"-0.375" | 0.575" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,050 | 820 | 25 | 000000000 | 00000 |

| 0.376"-0.5" | 0.7" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,050 | 820 | 25 | 000000000 | 00000 |

| 0.501"-0.625" | 0.85" | 0.192"-0.196" | No. 11 | 0.375" | 0.06" | 1,050 | 820 | 25 | 000000000 | 00000 |

1/4" Dia. | ||||||||||

| 0.126"-0.25" | 0.5" | 0.257"-0.261" | F | 0.5" | 0.08" | 1,750 | 1,450 | 25 | 000000000 | 00000 |

| 0.251"-0.375" | 0.625" | 0.257"-0.261" | F | 0.5" | 0.08" | 1,750 | 1,450 | 25 | 000000000 | 00000 |

| 0.376"-0.5" | 0.75" | 0.257"-0.261" | F | 0.5" | 0.08" | 1,750 | 1,450 | 10 | 000000000 | 0000 |

| 0.501"-0.625" | 0.9" | 0.257"-0.261" | F | 0.5" | 0.08" | 1,750 | 1,450 | 10 | 000000000 | 00000 |

Aluminum Domed Head High-Strength Blind Rivets

Lightweight and nonmagnetic, these rivets have good corrosion resistance. The mandrel expands the body of these rivets to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

1/8" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.063"-0.125" | 0.275" | 0.129"-0.133" | No. 30 | 0.25" | 0.042" | 220 | 250 | IFI 119 Standards | 25 | 000000000 | 000000 |

| 0.094"-0.187" | 0.337" | 0.129"-0.133" | No. 30 | 0.25" | 0.042" | 220 | 250 | IFI 119 Standards | 10 | 000000000 | 0000 |

| 0.126"-0.25" | 0.4" | 0.129"-0.133" | No. 30 | 0.25" | 0.042" | 220 | 250 | IFI 119 Standards | 10 | 000000000 | 0000 |

5/32" Dia. | |||||||||||

| 0.126"-0.25" | 0.425" | 0.16"-0.164" | No. 20 | 0.312" | 0.05" | 320 | 320 | IFI 119 Standards | 10 | 000000000 | 0000 |

| 0.251"-0.375" | 0.55" | 0.16"-0.164" | No. 20 | 0.312" | 0.05" | 320 | 320 | IFI 119 Standards | 10 | 000000000 | 0000 |

3/16" Dia. | |||||||||||

| 0.126"-0.25" | 0.45" | 0.192"-0.196" | No. 11 | 0.375" | 0.057" | 500 | 450 | IFI 119 Standards | 10 | 000000000 | 0000 |

| 0.251"-0.375" | 0.575" | 0.192"-0.196" | No. 11 | 0.375" | 0.057" | 500 | 450 | IFI 119 Standards | 10 | 000000000 | 0000 |

18-8 Stainless Steel Wide-Thickness-Range

Domed Head High-Strength Blind Rivets

18-8 stainless steel has good corrosion resistance and may be mildly magnetic. These rivets can grip a wider range of material thicknesses than standard high-strength rivets. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

3/16" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.062"-0.272" | 0.415" | 0.191"-0.201" | No. 11 | 0.385" | 0.085" | 1,300 | 1,050 | IFI 134 Standards | 10 | 000000000 | 00000 |

| 0.062"-0.437" | 0.582" | 0.191"-0.201" | No. 11 | 0.4" | 0.101" | 1,300 | 950 | IFI 134 Standards | 10 | 000000000 | 00000 |

1/4" Dia. | |||||||||||

| 0.083"-0.375" | 0.56" | 0.261"-0.272" | I | 0.525" | 0.117" | 2,350 | 1,800 | IFI 134 Standards | 10 | 000000000 | 00000 |

| 0.35"-0.625" | 0.81" | 0.261"-0.272" | I | 0.525" | 0.117" | 2,350 | 1,800 | IFI 134 Standards | 10 | 000000000 | 00000 |

Aluminum Wide-Thickness-Range Domed Head High-Strength Blind Rivets

Lightweight and nonmagnetic, these rivets have good corrosion resistance. They can grip a wider range of material thicknesses than standard high-strength rivets. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

3/16" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.062"-0.27" | 0.415" | 0.191"-0.201" | No. 11 | 0.385" | 0.085" | 500 | 400 | IFI 134 Standards | 50 | 000000000 | 000000 |

| 0.062"-0.437" | 0.57" | 0.191"-0.201" | No. 11 | 0.4" | 0.085" | 550 | 450 | IFI 134 Standards | 50 | 000000000 | 00000 |

| 0.214"-0.437" | 0.57" | 0.191"-0.201" | No. 11 | 0.4" | 0.085" | 550 | 450 | IFI 134 Standards | 25 | 000000000 | 0000 |

1/4" Dia. | |||||||||||

| 0.083"-0.374" | 0.56" | 0.261"-0.272" | I | 0.53" | 0.12" | 1,150 | 750 | IFI 134 Standards | 25 | 000000000 | 00000 |

| 0.083"-0.622" | 0.81" | 0.261"-0.272" | I | 0.53" | 0.12" | 1,150 | 750 | IFI 134 Standards | 25 | 000000000 | 00000 |

Zinc-Plated Steel Wide-Thickness-Range

Domed Head High-Strength Blind Rivets

The zinc-plated finish provides mild corrosion resistance. These rivets can grip a wider range of material thicknesses than standard high-strength rivets. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

3/16" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.062"-0.27" | 0.415" | 0.191"-0.201" | No. 10 | 0.4" | 0.085" | 1,250 | 1,200 | IFI 134 Standards | 50 | 000000000 | 000000 |

| 0.062"-0.437" | 0.582" | 0.191"-0.201" | No. 10 | 0.4" | 0.085" | 1,250 | 1,200 | IFI 134 Standards | 50 | 000000000 | 00000 |

| 0.214"-0.437" | 0.575" | 0.191"-0.201" | No. 11 | 0.401" | 0.09" | 1,280 | 920 | IFI 134 Standards | 25 | 000000000 | 00000 |

1/4" Dia. | |||||||||||

| 0.083"-0.374" | 0.56" | 0.261"-0.272" | I | 0.525" | 0.117" | 2,360 | 1,800 | IFI 134 Standards | 25 | 000000000 | 00000 |

| 0.35"-0.625" | 0.81" | 0.261"-0.272" | I | 0.592" | 0.12" | 2,400 | 1,850 | IFI 134 Standards | 25 | 000000000 | 00000 |

18-8 Stainless Steel Wide-Thickness-Range

Flush-Mount High-Strength Blind Rivets

18-8 stainless steel has good corrosion resistance. These rivets can grip a wider range of material thicknesses than standard high-strength rivets. Install in countersunk holes and the angled head sits flush with the material's surface. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Countersink Angle | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

3/16" Dia. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.125"-0.331" | 0.49" | 0.191"-0.201" | No. 11 | 0.35" | 0.08" | 100° | 1,300 | 950 | IFI 134 Standards | 10 | 000000000 | 000000 |

| 0.305"-0.5" | 0.66" | 0.191"-0.201" | No. 11 | 0.35" | 0.08" | 100° | 1,300 | 950 | IFI 134 Standards | 10 | 000000000 | 00000 |

1/4" Dia. | ||||||||||||

| 0.16"-0.437" | 0.665" | 0.261"-0.272" | I | 0.41" | 0.09" | 100° | 2,350 | 1,800 | IFI 134 Standards | 10 | 000000000 | 00000 |

| 0.415"-0.725" | 0.915" | 0.261"-0.272" | I | 0.41" | 0.09" | 100° | 2,350 | 1,800 | IFI 134 Standards | 10 | 000000000 | 00000 |

Aluminum Wide-Thickness-Range Flush-Mount High-Strength Blind Rivets

Lightweight and nonmagnetic, these rivets have good corrosion resistance. They can grip a wider range of material thicknesses than standard high-strength rivets. Install in countersunk holes and the angled head sits flush with the material's surface. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Use blind rivets to fasten material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Countersink Angle | Material | Specifications Met | Pkg. Qty. | Pkg. | |

3/16" Dia. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.125"-0.331" | 0.49" | 0.191"-0.201" | No. 10 | 0.35" | 0.08" | 500 | 580 | 100° | 5000 Series Aluminum | IFI 134 Standards | 10 | 000000000 | 000000 |

| 0.305"-0.5" | 0.66" | 0.191"-0.201" | No. 11 | 0.35" | 0.08" | 550 | 450 | 100° | 5000 Series Aluminum | IFI 134 Standards | 25 | 000000000 | 00000 |

1/4" Dia. | |||||||||||||

| 0.16"-0.475" | 0.81" | 0.261"-0.272" | I | 0.41" | 0.09" | 1,270 | 830 | 100° | 5056 Aluminum | IFI 134 Standards | 10 | 000000000 | 00000 |

| 0.415"-0.725" | 0.91" | 0.261"-0.272" | I | 0.41" | 0.09" | 1,270 | 830 | 100° | 5056 Aluminum | IFI 134 Standards | 5 | 000000000 | 0000 |

Large-Diameter Domed Head High-Strength Blind Rivets

A 50% larger head diameter than standard domed head blind rivets distributes pressure where the head meets the material surface. Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing. The mandrel expands the rivet body to completely fill the hole, providing the highest shear and tensile strengths of all the blind rivets we offer. The portion of the mandrel that's retained inside the rivet after installation won't loosen over time and fall out. Made of aluminum, rivets are lightweight, nonmagnetic, and resist mild corrosion. They join material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Material | Mandrel Material | Specifications Met | Pkg. Qty. | Pkg. | |

Aluminum Mandrel | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

3/16" Dia. | |||||||||||||

| 0.062"-0.27" | 0.416" | 0.191"-0.201" | No. 11 | 0.53" | 0.095" | 550 | 450 | 5056 Aluminum | Aluminum | IFI 134 Standards | 5 | 000000000 | 00000 |

| 0.062"-0.437" | 0.582" | 0.191"-0.201" | No. 11 | 0.53" | 0.095" | 550 | 450 | 5056 Aluminum | Aluminum | IFI 134 Standards | 5 | 000000000 | 0000 |

High-Strength Blind Rivets for Soft Materials

When installed, the rivet body splits into four legs to fasten plastic and fiberglass to thin materials, such as sheet metal. Made of aluminum, these rivets are lightweight, nonmagnetic, and have good corrosion resistance. They join material when you only have access to one side. A low-profile domed head creates a finished appearance.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Material | Pkg. Qty. | Pkg. | |

Steel Mandrel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

1/8" Dia. | |||||||||||

| 0.039"-0.138" | 0.335" | 0.129" | No. 30 | 0.247" | 0.051" | 180 | 210 | 5154 Aluminum | 100 | 000000000 | 000000 |

| 0.098"-0.197" | 0.433" | 0.142" | No. 27 | 0.256" | 0.048" | 180 | 210 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.177"-0.276" | 0.512" | 0.142" | No. 27 | 0.256" | 0.048" | 180 | 210 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.256"-0.354" | 0.571" | 0.129" | No. 30 | 0.247" | 0.051" | 180 | 210 | 5154 Aluminum | 100 | 000000000 | 00000 |

| 0.335"-0.433" | 0.669" | 0.142" | No. 27 | 0.256" | 0.048" | 180 | 210 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.413"-0.511" | 0.748" | 0.129" | No. 30 | 0.264" | 0.051" | 220 | 270 | 5154 Aluminum | 100 | 000000000 | 00000 |

5/32" Dia. | |||||||||||

| 0.039"-0.118" | 0.354" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.098"-0.197" | 0.433" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.177"-0.256" | 0.512" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.236"-0.315" | 0.59" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.295"-0.394" | 0.669" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.354"-0.422" | 0.748" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.452"-0.551" | 0.827" | 0.173" | No. 17 | 0.315" | 0.059" | 310 | 450 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.531"-0.63" | 0.826" | 0.165" | No. 19 | 0.331" | 0.067" | 320 | 320 | 5154 Aluminum | 100 | 000000000 | 00000 |

| 0.61"-0.826" | 1.023" | 0.165" | No. 19 | 0.331" | 0.067" | 320 | 320 | 5154 Aluminum | 100 | 000000000 | 00000 |

3/16" Dia. | |||||||||||

| 0.039"-0.118" | 0.414" | 0.196" | No. 9 | 0.363" | 0.079" | 400 | 350 | 5154 Aluminum | 100 | 000000000 | 00000 |

| 0.098"-0.197" | 0.433" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 100 | 000000000 | 00000 |

| 0.177"-0.276" | 0.512" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.256"-0.354" | 0.59" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.335"-0.394" | 0.669" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.375"-0.472" | 0.748" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.453"-0.551" | 0.827" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.531"-0.748" | 1.024" | 0.204" | No. 6 | 0.374" | 0.063" | 450 | 600 | 5052 Aluminum | 50 | 000000000 | 00000 |

| 0.728"-0.866" | 1.102" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 100 | 000000000 | 00000 |

| 0.846"-0.984" | 1.22" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 50 | 000000000 | 00000 |

| 0.964"-1.063" | 1.248" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 50 | 000000000 | 00000 |

| 1.043"-1.181" | 1.417" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 50 | 000000000 | 00000 |

| 1.161"-1.26" | 1.614" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 50 | 000000000 | 00000 |

| 1.24"-1.456" | 1.81" | 0.196" | No. 9 | 0.398" | 0.079" | 400 | 350 | 5154 Aluminum | 50 | 000000000 | 00000 |

1/4" Dia. | |||||||||||

| 0.748"-0.984" | 1.417" | 0.26" | G | 0.528" | 0.106" | 550 | 780 | 5154 Aluminum | 50 | 000000000 | 00000 |

| 1.339"-1.575" | 2.007" | 0.26" | G | 0.528" | 0.106" | 550 | 780 | 5154 Aluminum | 25 | 000000000 | 00000 |

| 2.52"-2.756" | 3.188" | 0.26" | G | 0.528" | 0.106" | 550 | 780 | 5154 Aluminum | 10 | 000000000 | 00000 |