About Sump, Water-Removal, Condensate, and Submersible Pumps

More

How to Prime Your Pump

More

How to Determine Feet of Head

More

About Process Pumps

More

About Drum Pumps

More

Circulation Pumps for Fuel and Flammable Liquid

Pump fuel and flammable liquids, such as isopropyl alcohol and xylene. These pumps have an explosion-proof motor that is rated for environments where hazardous material is present. Maximum temperature is 250° F or the boiling point of the liquid being pumped, whichever is lower. The motor is totally enclosed fan-cooled (TEFC) for use in dusty, dirty, and damp environments. Pumps are gravity fed and require an elevated liquid source. Do not run dry or use with solids.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

For technical drawings and 3-D models, click on a part number.

Pumps | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Pipe Size | Overall | Replacement Impellers | |||||||||||||||

| Max. Flow Rate, gpm | @ 10 ft. of Head | @ 20 ft. of Head | @ 40 ft. of Head | @ 60 ft. of Head, gpm | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | hp | Current, A | Intake (Female, NPT) | Discharge (Female, NPT) | Lg. | Wd. | Ht. | Each | Each | ||

120/208-240V AC, Single Phase—Hardwire | ||||||||||||||||||

| 25 | 31 | 25 | 13 | 1 | 62 | 150 | 264 | 1/2 | 7.4/3.7 | 3/4 | 1/2 | 15 5/8" | 10 7/8" | 7 1/2" | 0000000 | 000000000 | 00000000 | 0000000 |

208-240/460V AC, Three Phase—Hardwire | ||||||||||||||||||

| 25 | 31 | 25 | 13 | 1 | 62 | 150 | 264 | 1/2 | 2.4-2.2/1.1 | 3/4 | 1/2 | 15 5/8" | 10 7/8" | 7 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| 100 | __ | 78 | 48 | 10 | 64 | 150 | 264 | 1 | 2.8/1.4 | 1 1/2 | 1 | 15 1/4" | 10 7/8" | 8 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| Maintenance Kit | 00000000 | Each | 0000000 |

Pumps | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Pipe Size | Overall | Replacement Impellers | |||||||||||||||

| Max. Flow Rate, gpm | @ 20 ft. of Head | @ 30 ft. of Head | @ 40 ft. of Head | @ 60 ft. of Head, gpm | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | hp | Current, A | Intake (Female, NPT) | Discharge (Female, NPT) | Lg. | Wd. | Ht. | Each | Each | ||

120/208-240V AC, Single Phase—Hardwire | ||||||||||||||||||

| 15 | __ | 10 | 4 | __ | 46 | 150 | 264 | 1/3 | 4.8/2.4 | 3/4 | 1/2 | 15 1/2" | 10 7/8" | 7 1/2" | 0000000 | 000000000 | 00000000 | 0000000 |

| 100 | 78 | 64 | 48 | 10 | 64 | 150 | 264 | 1 | 12/6 | 1 1/2 | 1 | 17 1/4" | 10 7/8" | 8 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

208-240/460V AC, Three Phase—Hardwire | ||||||||||||||||||

| 115 | __ | 100 | 90 | 60 | 81 | 150 | 264 | 1 1/2 | 5-4.6/2.3 | 1 1/2 | 1 | 16 3/8" | 11 7/8" | 8 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| 125 | 114 | 98 | 78 | 18 | 69 | 150 | 264 | 2 | 5.7-5.4/2.7 | 2 | 1 1/2 | 17 1/8" | 11 7/8" | 8 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| 140 | __ | __ | 120 | 47 | 75 | 150 | 264 | 3 | 8.1-7.6/3.8 | 2 | 1 1/2 | 17 1/8" | 11 7/8" | 8 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| Maintenance Kit | 00000000 | Each | 0000000 |

Self-Priming Circulation Pumps without Motor for Water

Also known as flexible impeller pumps, these create a suction force that can draw liquid upward to fill the pump chamber when your liquid source is below the pump. The impeller resists clogging and wear. Select a spark-free air motor for hazardous environments or attach an electric motor with a speed reducer or a belt pulley to alter the pump speed.

Repair kits (sold separately) include components such as impellers, O-rings, and seal lips.

Note: Pumps must be filled with liquid before use. They need a constant flow of liquid and cannot run dry.

For technical drawings and 3-D models, click on a part number.

Intake (NPT) | Discharge (NPT) | Overall | Shaft | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity | Temp. Range, °F | Required hp | Gender | Pipe Size | Gender | Pipe Size | Ht. | Lg. | Wd. | Dia. | Lg. | Ctr.-to-Base Lg. | Each | |

For 500 rpm-2,100 rpm Motor Speed | |||||||||||||||||

| 13 | 60 | 26 | Not Rated | 50° to 180° | 1/3 | Female | 1/2 | Female | 1/2 | 3 13/16" | 4 1/2" | 4 1/8" | 5/8" | 1 1/8" | 1 15/16" | 0000000 | 0000000 |

| 27.9 | 60 | 26 | Not Rated | 50° to 180° | 3/4 | Female | 1 | Female | 1 | 3 9/16" | 6 3/8" | 4 3/4" | 5/8" | 2 1/4" | 1 7/8" | 0000000 | 000000 |

Self-Priming Circulation Pumps without Motor for Oil

Use these pumps to move lubricating oil such as hydraulic and motor oil. Also known as flexible impeller pumps, they create a suction force that can draw liquid upward to fill the pump chamber when your liquid source is below the pump. The impeller resists clogging and wear. Select a spark-free air motor for hazardous environments or attach an electric motor with a speed reducer or a belt pulley to alter the pump speed.

Repair kits (sold separately) include components such as impellers, O-rings, and seal lips.

Note: Pumps must be filled with liquid before use. They need a constant flow of liquid and cannot run dry.

For technical drawings and 3-D models, click on a part number.

Intake (NPT) | Discharge (NPT) | Shaft | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Max. Ft. of Head, ft. | Max. Pressure, psi | Max. Viscosity | Temp. Range, °F | Required hp | Gender | Pipe Size | Gender | Pipe Size | Dia. | Lg. | Ctr.-to-Base Lg. | Ht. | Lg. | Wd. | Each | |

For 500 rpm-2,100 rpm Motor Speed | |||||||||||||||||

| 11.5 | 50 | 21 | Not Rated | 50° to 180° | 1/3 hp | Female | 1/2 | Female | 1/2 | 5/8" | 1 1/8" | 1 15/16" | 3 13/16" | 4 1/2" | 4 1/8" | 0000000 | 0000000 |

| 25 | 50 | 26 | Not Rated | 50° to 180° | 3/4 hp | Female | 1 | Female | 1 | 5/8" | 2 1/4" | 1 7/8" | 3 9/16" | 6 3/8" | 4 3/4" | 0000000 | 000000 |

Electric Drum Pump Systems for Water, Oil, Coolants, and Chemicals

Including nozzles and connectors, these pumps come with everything you need to start pumping. All include a pump assembly, 1" ID hose, dispensing nozzle, drum connector, and storage bracket.

Pumps with a 316 stainless steel housing are often used with fuel, acetone, methyl ethyl ketone (MEK), xylene, and mineral spirits. Their motors are rated IP55 and are CSA certified for use in Class I, Divisions 1 and 2, Group D hazardous environments with flammable gases and vapors.

For technical drawings and 3-D models, click on a part number.

Temp. Range, °F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Environmental Rating | Each | |

120V AC, Single Phase—Hardwire | ||||||||||||||||

316 Stainless Steel Housing | ||||||||||||||||

| 18 | 15 | 55 | 1,000 | Not Rated | 175° | 1 1/3 hp | 9.1 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | NEC Class I Divisions 1, 2 Group D IP55 | 0000000 | 000000000 |

Hazardous Location Electric Drum Pumps

for Water, Oil, Coolants, and Chemicals

These pumps quickly empty drum contents by moving 48 gallons of liquid per minute. They are often used with lubricating oil as well as with chemicals such as detergents and etching and cleaning solutions. Their electric motors are explosion proof and UL listed for Class I, Divisions 1 and 2, Groups C and D; and Class II, Division 2, Groups F and G environments where flammable gases and combustible dust may be present.

Pumps | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. Range, °F | Intake | Discharge | Maintenance Parts | |||||||||||||

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size | Tube OD | Tube Lg. | Tube Connection Type | For Tube ID | Thermal Protection | Each | ||

120V AC, Single Phase | ||||||||||||||||

Hardwire | ||||||||||||||||

| 48.5 | 14 | 55 | 300 | -40° | 210° | 1/2 hp | 5.3 | 41 mm | 1 5/8" | 39" | Barbed | 1" | With Thermal Overload Protection | 00000000 | 000000000 | 00000000 |

Sanitary Electric Drum Pumps

Commonly used in food, beverage, pharmaceutical, and cosmetic processing, these pumps are designed for sanitary environments. The discharge connection can be easily disassembled for cleaning. Pumps do not include a drum connector.

Pumps that are 3-A certified meet sanitary design standards. Those that are CSA certified meet stringent safety standards.

For technical drawings and 3-D models, click on a part number.

Temp. Range, °F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size, mm | Tube OD | Tube Lg. | Tube Connection Type | For Tube OD | Thermal Protection | Specifications Met | Each | |

115V AC, Single Phase—Hardwire | ||||||||||||||||

Nylon Plastic Housing | ||||||||||||||||

| 31 | 10 | 55 | 1,000 | 15° | 175° | 1 hp | 4.2 | 38 | 1 1/2" | 39" | Quick Clamp | 1 1/2" | With Thermal Overload Protection | 3-A Certified 02-11; CSA Certified | 0000000 | 000000000 |

Hazardous Location High-Flow Battery-Operated

Drum Pumps with Nozzle for Fuel

These pumps are C-UL listed for Class I, Division 2, Group D for use in environments with flammable gases. Operating on a 12-volt battery, use them to transfer and drain fuel such as gasoline, diesel fuel, and kerosene. Lock the nozzle with a padlock (not included).

Always bond and ground your application for static control. For more information about bonding and grounding, see Sections 1910.106 and 1910.107 of the Federal OSHA Code or see bonding and grounding equipment.

Pumps with automatic shut-off nozzle turn off when the tank is full.

Temp. Range, °F | Intake | Discharge (Hose and Nozzle) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | Max. Lift, ft. | For Drum Opening Size | Includes | Pipe Size | Gender | Thread Type | ID | Lg., ft. | Nozzle Type | Max. Shackle Dia. | Thermal Protection | Each | |

12V DC | |||||||||||||||||||

| 25 | 20 | 10 | -20° | 125° | 4/10 hp | 35 | 15 | 2 NPT | 18-ft. Battery Cable, Drum Connector | 1 | Female | NPT | 1" | 18 | Automatic Shut-Off, Lockable | 5/16" | With Thermal Overload Protection | 0000000 | 000000000 |

| 25 | 20 | 10 | -20° | 125° | 4/10 hp | 35 | 15 | 2 NPT | 18-ft. Battery Cable, Drum Connector | 1 | Female | NPT | 1" | 18 | Manual Shut-Off, Lockable | 5/16" | With Thermal Overload Protection | 0000000 | 000000 |

Air-Powered Drum Pumps for Flammable Liquid

These pumps have a motor that is rated for IEC Zone 1, Groups IIB and IIA; and IEC Zone 21, Groups IIIC, IIIB, and IIIA hazardous locations with flammable gases and vapors, so they can be used with liquids such as acetone, ethanol, methyl ethyl ketone (MEK), xylene, and mineral spirits. Motor is nonsparking for use in applications where electricity is unavailable or dangerous. Install an air line filter/lubricator to ensure efficiency and reduce wear on the pump.

Always bond and ground your application for static control. For more information about bonding and grounding, see Sections 1910.106 and 1910.107 of the Federal OSHA Code or see bonding and grounding equipment.

For technical drawings and 3-D models, click on a part number.

Temp. Range, °F | Air Connection | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure Range, psi | Air Consumption, cfm | For Drum Opening Size | Includes | Pipe Size | Gender | Thread Type | Tube OD | Tube Lg. | Tube Connection Type | For Tube ID | Each | |

| 26 | 55 | 1,100 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 39" | Barbed | 1" | 0000000 | 000000000 |

| 26 | 55 | 1,100 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 47" | Barbed | 1" | 0000000 | 00000000 |

| 53 | 55 | 1,000 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 39" | Barbed | 1" | 0000000 | 00000000 |

| 53 | 55 | 1,000 | -40° | 210° | 44-87 | 53 | 2 NPT | Drum Connector | 3/8 | Female | NPT | 1 5/8" | 47" | Barbed | 1" | 0000000 | 00000000 |

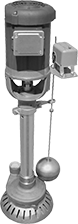

Hazardous Location Sump Pumps for Hot Water

These pumps have an explosion-proof motor that is rated for use where hazardous material is present. Since the motor is totally enclosed fan cooled (TEFC) and never comes into contact with the water, the pump can be used with hot water up to 300° F. A pedestal-mounted motor design provides easy access for maintenance. The float switch has a separate cord that can unplug, so you can replace the switch without replacing the whole pump.

Hazardous location environmental ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Before selecting a product for a hazardous location, ensure it is rated for your environment. See About Hazardous Location Environmental Ratings.

Max. Flow Rate, gpm | Level | Discharge | Min. Sump Pit | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 Ft. of Head | @ 10 Ft. of Head | @ 15 Ft. of Head | Max. Ft. of Head, ft. | Max. Solids Dia. | Turn On | Turn Off | Temp. Range, °F | Horsepower | Pipe Size | Thread Type | Gender | Dia. | Dp. | Ht. | Wd. | Lg. | | Each | |

120/240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

Hardwire | |||||||||||||||||||

| 60 | 60 | 45 | 32 | 1/4" | 24" | 6" | 40° to 300° | 1/2 hp | 1 1/2 | NPT | Female | 16" | 24" | 42" | 17" | 15" | 4.9A | 0000000 | 000000000 |